Technology peripherals

Technology peripherals

It Industry

It Industry

Foxconn builds AI one-stop service, and invested Sharp to enter advanced semiconductor packaging: put into production in 2026, designed to produce 20,000 wafers per month

Foxconn builds AI one-stop service, and invested Sharp to enter advanced semiconductor packaging: put into production in 2026, designed to produce 20,000 wafers per month

Foxconn builds AI one-stop service, and invested Sharp to enter advanced semiconductor packaging: put into production in 2026, designed to produce 20,000 wafers per month

News from this site on July 11, Economic Daily reported today (July 11) that Foxconn Group has entered the advanced packaging field, focusing on the current mainstream panel-level fan-out packaging (FOPLP) semiconductor solution.

- Foxconn Group itself has sufficient influence in the AI field, and by making up for its shortcomings in advanced packaging, it can provide "one-stop" services to facilitate the acceptance of more AI product orders in the future.

- According to public information on this website, Foxconn Group currently holds 10.5% of Sharp’s shares. The group stated that it will not increase or reduce its holdings at this stage and will maintain the existing investment relationship.

- Sharp announced that it will join hands with Japanese electronic component manufacturer Aoi Electronics to enter the advanced packaging field. Aoi will renovate existing Sharp factories and facilities and build semiconductor packaging production lines.

- Aoi plans to build an advanced semiconductor panel packaging production line at Sharp's factory in 2024, with a target of full production in 2026, with a monthly production capacity of 20,000 pieces.

The above is the detailed content of Foxconn builds AI one-stop service, and invested Sharp to enter advanced semiconductor packaging: put into production in 2026, designed to produce 20,000 wafers per month. For more information, please follow other related articles on the PHP Chinese website!

Hot AI Tools

Undresser.AI Undress

AI-powered app for creating realistic nude photos

AI Clothes Remover

Online AI tool for removing clothes from photos.

Undress AI Tool

Undress images for free

Clothoff.io

AI clothes remover

Video Face Swap

Swap faces in any video effortlessly with our completely free AI face swap tool!

Hot Article

Hot Tools

Notepad++7.3.1

Easy-to-use and free code editor

SublimeText3 Chinese version

Chinese version, very easy to use

Zend Studio 13.0.1

Powerful PHP integrated development environment

Dreamweaver CS6

Visual web development tools

SublimeText3 Mac version

God-level code editing software (SublimeText3)

Hot Topics

Innolux plans to mass-produce fan-out panel-level semiconductor packaging technology by the end of the year

Aug 07, 2024 pm 06:18 PM

Innolux plans to mass-produce fan-out panel-level semiconductor packaging technology by the end of the year

Aug 07, 2024 pm 06:18 PM

According to news from this site on August 6, Yang Zhuxiang, general manager of Innolux Corporation, said yesterday (August 5) that the company is actively deploying and promoting semiconductor fan-out panel-level packaging (FOPLP) and is expected to mass-produce ChipFirst before the end of this year. The contribution of process technology to revenue will be apparent in the first quarter of next year. Fenye Innolux stated that it is expected to mass-produce the redistribution layer (RDLFirst) process technology for mid-to-high-end products in the next 1-2 years, and will work with partners to develop the most technically difficult glass drilling (TGV) process, which will take another 2-3 years. It can be put into mass production within a year. Yang Zhuxiang said that Innolux’s FOPLP technology is “ready for mass production” and will enter the market with low-end and mid-range products.

Sharp is considering selling its semiconductor and camera module businesses to Hon Hai for an undisclosed amount

Aug 13, 2024 am 10:36 AM

Sharp is considering selling its semiconductor and camera module businesses to Hon Hai for an undisclosed amount

Aug 13, 2024 am 10:36 AM

According to news from this website on August 12, Sharp announced on August 9 that it is considering selling its semiconductor business and smartphone camera module business to Hon Hai within this fiscal year. Regarding the sale amount, Sharp President Masahiro Okitsu said that since the negotiations have just begun, it is not convenient to disclose more details at the moment. ▲Picture source: Sharp’s website noticed that as early as July 11, there were reports that Foxconn Group has entered the advanced packaging field, focusing on the current mainstream panel-level fan-out packaging (FOPLP) semiconductor solution. Following its subsidiary Innolux, Sharp, invested by Foxconn Group, also announced its entry into Japan's panel-level fan-out packaging field and is expected to be put into production in 2026. Public information shows that Foxconn Group currently holds 10.5% of Sharp’s shares.

Sharp AQUOS wish4 mobile phone released: Dimensity 700 processor, Miyake design, overseas launch in early July

May 08, 2024 pm 09:10 PM

Sharp AQUOS wish4 mobile phone released: Dimensity 700 processor, Miyake design, overseas launch in early July

May 08, 2024 pm 09:10 PM

According to news on May 8, the entry-level Sharp AQUOSwish4 mobile phone was released at the same time as the AQUOS R9. It was also designed by Miyake Design and will be launched in early July. Sharp AQUOSwish4 mobile phone uses a soft-touch matte plastic body, about 60% of which is recycled plastic, and is available in three colors: blue, white, and black. The phone complies with 18 MIL-STD-810H military regulations and has passed IPX5/8 waterproof and IP6X dustproof certifications. The phone is equipped with a 6.6-inch 720p90Hz water drop LCD screen on the front, the same Dimensity 700 processor as the previous generation Wish3, 4GB of memory and 64GB of storage, and the battery capacity has been upgraded to 5000mAh. New machines

Sharp launches commercial NAS device BP-X2ST: 4-bay design, pre-built RAID

Mar 06, 2024 pm 09:13 PM

Sharp launches commercial NAS device BP-X2ST: 4-bay design, pre-built RAID

Mar 06, 2024 pm 09:13 PM

According to news from this website on March 6, Sharp recently launched the commercial NAS device BP-X2ST in Japan. This NAS is designed with 4 bays and pre-built RAID. According to this site’s understanding, BP-X2ST is affiliated to Sharp’s office service brand COCOROOFFICE and is targeted at small and medium-sized enterprises and the office market. Therefore, it is provided as a finished product with pre-installed hard drives and pre-built RAID. The NAS is equipped with dual 2.5G network ports, with a 10G USB Type-A interface on the front panel, a 10G Type-A interface and 2 USB2.0 Type-A interfaces on the rear. BP-X2ST provides 3 effective capacity versions, namely 2TB, 4TB and 8TB. The 2TB version is dual 2TB mechanical hard drive RAID1

TrendForce: Nvidia's Blackwell platform products drive TSMC's CoWoS production capacity to increase by 150% this year

Apr 17, 2024 pm 08:00 PM

TrendForce: Nvidia's Blackwell platform products drive TSMC's CoWoS production capacity to increase by 150% this year

Apr 17, 2024 pm 08:00 PM

According to news from this site on April 17, TrendForce recently released a report, believing that demand for Nvidia's new Blackwell platform products is bullish, and is expected to drive TSMC's total CoWoS packaging production capacity to increase by more than 150% in 2024. NVIDIA Blackwell's new platform products include B-series GPUs and GB200 accelerator cards integrating NVIDIA's own GraceArm CPU. TrendForce confirms that the supply chain is currently very optimistic about GB200. It is estimated that shipments in 2025 are expected to exceed one million units, accounting for 40-50% of Nvidia's high-end GPUs. Nvidia plans to deliver products such as GB200 and B100 in the second half of the year, but upstream wafer packaging must further adopt more complex products.

SK hynix's innovative semiconductor CMP polishing pad technology enables sustainable use

Dec 28, 2023 pm 11:04 PM

SK hynix's innovative semiconductor CMP polishing pad technology enables sustainable use

Dec 28, 2023 pm 11:04 PM

According to news from this website on December 27, according to Korean media ETNews, SK Hynix has recently developed reusable CMP polishing pad technology, which can not only reduce costs, but also enhance ESG (environmental, social, governance) management. SK Hynix said that they will first deploy reusable CMP polishing pads in low-risk processes and gradually expand their application scope. Note: CMP technology is to make the surface of the material to be polished under the combined action of chemicals and mechanics. A process to achieve the required flatness. The chemical components in the polishing fluid react chemically with the material surface to form a softened layer that is easy to polish. The polishing pad and abrasive particles in the polishing fluid physically and mechanically polish the material surface to remove the softened layer. Source: Dinglong shares in CM

Sony Group: Its semiconductor factories concealed emissions of harmful substances

Jul 12, 2024 pm 02:09 PM

Sony Group: Its semiconductor factories concealed emissions of harmful substances

Jul 12, 2024 pm 02:09 PM

According to reports from this website on July 8, based on reports from Nikkei and Japan's "Jiji News Agency", on the 8th (today) local time, Sony Semiconductor Manufacturing Company, a semiconductor manufacturer under the Sony Group, announced that the company had discharged harmful chemicals outside the factory. , and no notification was made. The company said this was due to an input error and an imperfect confirmation system. In fiscal years 2021 and 2022, the camera image sensor factory located in Kikuyo Town, Kumamoto Prefecture, incorrectly reported its emissions of chemical substances as 0. The actual situation was that there were emissions of "waste without harmless treatment." The plant emits hydrogen fluoride, which is commonly used in semiconductor processing and cleaning. Note from this site: Hydrogen fluoride is harmful to the human body and can cause respiratory diseases and even life-threatening effects when inhaled. sony half

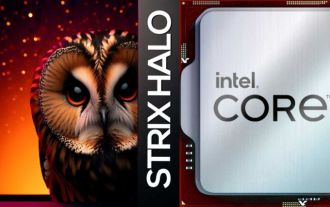

AMD 'Strix Halo” FP11 package size exposed: equivalent to Intel LGA1700, 60% larger than Phoenix

Jul 18, 2024 am 02:04 AM

AMD 'Strix Halo” FP11 package size exposed: equivalent to Intel LGA1700, 60% larger than Phoenix

Jul 18, 2024 am 02:04 AM

This website reported on July 9 that the AMD Zen5 architecture "Strix" series processors will have two packaging solutions. The smaller StrixPoint will use the FP8 package, while the StrixHalo will use the FP11 package. Source: videocardz source @Olrak29_ The latest revelation is that StrixHalo’s FP11 package size is 37.5mm*45mm (1687 square millimeters), which is the same as the LGA-1700 package size of Intel’s AlderLake and RaptorLake CPUs. AMD’s latest Phoenix APU uses an FP8 packaging solution with a size of 25*40mm, which means that StrixHalo’s F