Backend Development

Backend Development

PHP Tutorial

PHP Tutorial

What are the maintenance tips for EPSON printer continuous ink supply system? Page 1/2_PHP Tutorial

What are the maintenance tips for EPSON printer continuous ink supply system? Page 1/2_PHP Tutorial

What are the maintenance tips for EPSON printer continuous ink supply system? Page 1/2_PHP Tutorial

This blockage will cause the ejected ink droplets to become smaller or the ejected ink to have obvious bifurcation, resulting in insufficient coverage of the ink droplets on the paper. The positioning is offset, so the printed artwork feels coarse-grained. Severe blockage results in lack of color. In addition, the purpose of installing a permanent chip is to save ink, but the EPSON printer does not clean the nozzle when it is turned on, causing the nozzle to become clogged and then cleaning it vigorously, which not only fails to save ink, but also causes more waste of printing paper and ink.

------ The continuous ink supply system makes people happy and worried

The continuous ink supply system has a certain user base in the market because of its low price. This system first appeared at the end of 2002. After development in 2003, it became popular in 2004. Ordinary home users usually do not use this system because their monthly ink consumption is not very large. Some profit-oriented business output users, such as printing companies and advertising companies, have a special preference for continuous supply systems because they have a large monthly printing volume. As small and medium-sized enterprises, they particularly want to control costs. Generally speaking, the size of these enterprises will range from a few to twenty people. Companies generally use two or three EPSON printers, and the monthly ink consumption is about seven or eight sets. Using a continuous ink supply system can help them save a lot of money on purchasing ink cartridges every month.

Second, as a plug-in product, the continuous ink supply system changes the structure of the EPSON printer. All functions of the EPSON printer cannot be realized, resulting in malfunctions, such as serious clogging. Since the continuous supply system is an external device that transports ink through long pipes, it is easy for air to enter and cause bubbles. In addition, non-original genuine ink is easy to be mixed with impurities because the production conditions are not guaranteed. These are the culprits of causing clogging.

First of all, the current continuous ink supply system technology is not yet mature, and the product quality is uneven. Some small and medium-sized dealers are driven by profits to operate some off-brand products. Factory name, factory address, etc., so the quality of the ink cannot be guaranteed. This is why users feel that the color effect printed with continuous ink is not as good as that printed with original ink.

In addition, due to the pressure imbalance in the continuous supply system, the ink will leak from the print head to the waste ink pad. If it is in this state for a long time, the ink will accumulate and leak out and even flow to the table. If the waste ink flows to the power board or control board of the EPSON printer, it will cause a short circuit on the circuit board, causing damage to the EPSON printer. Even if the waste ink does not overflow, when the EPSON printer has excessive waste ink, the vapor emitted from the waste ink pad will cause damage to the EPSON printer circuit board, operating mechanism and even the nozzle. On the contrary, if you use the original ink from the EPSON printer manufacturer, less ink will be consumed during power-on flushing, and the problem of the waste ink pad being full and causing ink leakage will not occur. Even if the waste ink pad is saturated due to long-term heavy printing, the machine will alarm in time, and the user only needs to go to the maintenance station to replace the waste ink pad with a new one.

Third, and the most troublesome problem for users of continuous ink supply systems, is that the waste ink pad is easily full. As we all know, if the EPSON printer is not in use, the ink in the nozzle will inevitably increase in viscosity due to evaporation of water or dry up and cause blockage. Therefore, the EPSON printer nozzle will automatically clean when the printer is turned on. After using the continuous supply plug-in system, due to the long pipeline transmission, the generation of waste ink is greatly increased when cleaning the nozzle, causing the waste ink pad to become full easily. In addition, a large amount of ink is required to clean the nozzle after the nozzle is blocked, which makes the waste ink pad overwhelmed.

So what is the difference between the continuous supply system and the original ink cartridge? Why does it cause so much trouble to people? Are consumers succumbing to low prices or are they sincere about print quality?

Hot AI Tools

Undresser.AI Undress

AI-powered app for creating realistic nude photos

AI Clothes Remover

Online AI tool for removing clothes from photos.

Undress AI Tool

Undress images for free

Clothoff.io

AI clothes remover

Video Face Swap

Swap faces in any video effortlessly with our completely free AI face swap tool!

Hot Article

Hot Tools

Notepad++7.3.1

Easy-to-use and free code editor

SublimeText3 Chinese version

Chinese version, very easy to use

Zend Studio 13.0.1

Powerful PHP integrated development environment

Dreamweaver CS6

Visual web development tools

SublimeText3 Mac version

God-level code editing software (SublimeText3)

Hot Topics

1386

1386

52

52

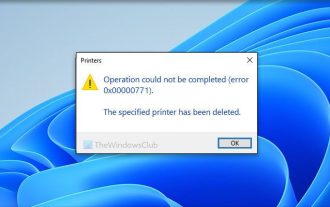

Unable to complete operation (Error 0x0000771) Printer error

Mar 16, 2024 pm 03:50 PM

Unable to complete operation (Error 0x0000771) Printer error

Mar 16, 2024 pm 03:50 PM

If you encounter an error message when using your printer, such as the operation could not be completed (error 0x00000771), it may be because the printer has been disconnected. In this case, you can solve the problem through the following methods. In this article, we will discuss how to fix this issue on Windows 11/10 PC. The entire error message says: The operation could not be completed (error 0x0000771). The specified printer has been deleted. Fix 0x00000771 Printer Error on Windows PC To fix Printer Error the operation could not be completed (Error 0x0000771), the specified printer has been deleted on Windows 11/10 PC, follow this solution: Restart Print Spool

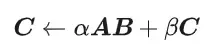

CUDA's universal matrix multiplication: from entry to proficiency!

Mar 25, 2024 pm 12:30 PM

CUDA's universal matrix multiplication: from entry to proficiency!

Mar 25, 2024 pm 12:30 PM

General Matrix Multiplication (GEMM) is a vital part of many applications and algorithms, and is also one of the important indicators for evaluating computer hardware performance. In-depth research and optimization of the implementation of GEMM can help us better understand high-performance computing and the relationship between software and hardware systems. In computer science, effective optimization of GEMM can increase computing speed and save resources, which is crucial to improving the overall performance of a computer system. An in-depth understanding of the working principle and optimization method of GEMM will help us better utilize the potential of modern computing hardware and provide more efficient solutions for various complex computing tasks. By optimizing the performance of GEMM

Huawei's Qiankun ADS3.0 intelligent driving system will be launched in August and will be launched on Xiangjie S9 for the first time

Jul 30, 2024 pm 02:17 PM

Huawei's Qiankun ADS3.0 intelligent driving system will be launched in August and will be launched on Xiangjie S9 for the first time

Jul 30, 2024 pm 02:17 PM

On July 29, at the roll-off ceremony of AITO Wenjie's 400,000th new car, Yu Chengdong, Huawei's Managing Director, Chairman of Terminal BG, and Chairman of Smart Car Solutions BU, attended and delivered a speech and announced that Wenjie series models will be launched this year In August, Huawei Qiankun ADS 3.0 version was launched, and it is planned to successively push upgrades from August to September. The Xiangjie S9, which will be released on August 6, will debut Huawei’s ADS3.0 intelligent driving system. With the assistance of lidar, Huawei Qiankun ADS3.0 version will greatly improve its intelligent driving capabilities, have end-to-end integrated capabilities, and adopt a new end-to-end architecture of GOD (general obstacle identification)/PDP (predictive decision-making and control) , providing the NCA function of smart driving from parking space to parking space, and upgrading CAS3.0

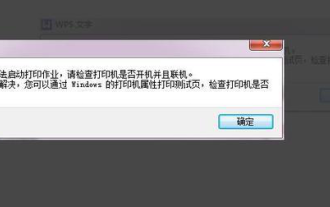

What should I do if WPS cannot start the printer job?

Mar 20, 2024 am 08:20 AM

What should I do if WPS cannot start the printer job?

Mar 20, 2024 am 08:20 AM

We can use office software to produce various electronic documents. Electronic documents greatly save the use of paper and are easier to save and read. However, sometimes according to work requirements, superiors require printing out paper documents for everyone to circulate. Document writing It's fine but unable to print. It's very difficult to encounter such a situation. The course we brought today can solve this problem. The following lesson is: What should I do if WPS cannot start the printer job? When trying to print a document using a LAN printer, a problem occurred, saying "WPSOffice cannot start the print job. Please check whether the printer is turned on and online." But in fact, the printer is powered on and online. 2. Click "OK", then click on the upper left corner of the title bar as shown in the picture

Lenovo Xiaoxin Panda Pro Panda Printer Pro goes on sale on May 6: black and white laser printing, built-in learning resources, 999 yuan

May 01, 2024 am 08:46 AM

Lenovo Xiaoxin Panda Pro Panda Printer Pro goes on sale on May 6: black and white laser printing, built-in learning resources, 999 yuan

May 01, 2024 am 08:46 AM

According to news from this site on April 30, Lenovo Xiaoxin PandaPro Panda Printer Pro is now available on JD.com. This printer will go on sale on May 6. It supports black and white laser printing, has an optional two-color body, and has built-in learning resources. The initial price is 999. Yuan. Lenovo Xiaoxin Panda Printer Pro measures 350x275x141mm and is available in two color options: Xiling White and Qingcheng Gray. This printer supports 2.4GHz/5GHz dual-band Wi-Fi, USB wired and other connection methods. It can print with one click after being configured with the network, and can also achieve NFC one-touch printing. Xiaoxin Panda Printer Pro supports black and white laser printing and can print 22 pages per minute. In addition to printing functions, this model also supports copying and scanning functions, with a color scanning resolution of 4800d.

Mobile phone directly connected to printer (explore various connection methods of mobile phone connected directly to printer)

Apr 25, 2024 pm 07:31 PM

Mobile phone directly connected to printer (explore various connection methods of mobile phone connected directly to printer)

Apr 25, 2024 pm 07:31 PM

Direct-connection of mobile phone printers has become an increasingly popular printing solution in modern life, as mobile devices become more popular and their functions continue to increase. To quickly print files, we can directly connect to the printer through our mobile phones without the need for a computer. To help you choose the printing solution that best suits your needs, this article will introduce you to the various connection methods for direct connection of your mobile phone to the printer. Wi-Fi direct printing Wi-Fi direct printing is currently one of the most common methods of directly connecting a mobile phone to a printer. By connecting the printer and mobile phone to the same Wi-Fi network, users can easily transfer and print files through the mobile app. Bluetooth direct printing Bluetooth direct printing is a simpler and more convenient way to connect a mobile phone directly to a printer. can realize the file

The Print Spooler service automatically shuts down and the printer cannot print normally.

Jun 18, 2024 pm 08:20 PM

The Print Spooler service automatically shuts down and the printer cannot print normally.

Jun 18, 2024 pm 08:20 PM

My friend's printer suddenly stopped printing. When WPS was printing, it prompted "The system print service has been closed" and "The system PrintSpooler service has been detected to be closed. Please enable it and try again." The PrintSpooler service executes print jobs in the background and handles interactions with the printer. . If you turn off the service, you cannot print or view the printer. According to the prompts, generally we only need to find the PrintSpooler service in the service, start it and change it to automatic. After my friend's computer started the PrintSpooler service, the service automatically stopped in about a minute and started again, and the same situation occurred. Saw spoolsv.exe and a dl through event viewer

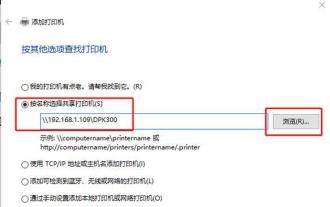

Steps on how to connect HP 136w printer to wifi. Must read: HP printer wireless connection tutorial

Feb 26, 2024 am 11:19 AM

Steps on how to connect HP 136w printer to wifi. Must read: HP printer wireless connection tutorial

Feb 26, 2024 am 11:19 AM

In fact, it is LAN printer sharing. The method is as follows: 1. Set the IP for the printer. First, plug the network from the router or switch to the printer. 2. Then click Printer Settings - Network Configuration - Wireless Menu. It is best to set a fixed IP for the printer there. Next, download and install the printer driver on your computer. When installing the driver, select the network installation option, so that the computer will automatically search for printers connected to the shared network. Once the installation is complete, the driver will show that the printer has been successfully shared wirelessly. How to connect the printer through a wireless network: 1. Right-click the WiFi icon under the desktop and select "Open Network and Sharing Center". 2. Click the name of the WiFi you are connected to, and a pop-up will appear.