Is the mouse an input device or an output device?

The mouse is an input device. The mouse is an external input device for the computer and an indicator for positioning the vertical and horizontal coordinates of the computer display system; it can position the cursor on the current screen and operate the screen elements where the cursor passes through the buttons and wheel device. An input device is a device for human or external interaction with a computer. It is used to input raw data and programs for processing these numbers into the computer; keyboard, mouse, camera, scanner, light pen, handwriting input pad, joystick, voice Input devices, etc. are all input devices.

The operating environment of this tutorial: windows7 system, DELL G3 computer

The mouse is an input device.

Input device: A device that inputs data and information into the computer.

Output device: It is a terminal device of a computer hardware system, used to receive computer data output display, printing, sound, control peripheral device operations, etc.

Input device (InputDevice) is a device for human or external interaction with the computer. It is used to input raw data and programs for processing these numbers into the computer. Computers can receive a variety of data, which can be numerical data or various non-numeric data, such as graphics, images, sounds, etc., which can be input into the computer through different types of input devices for processing. Storage, processing and output.

The keyboard, mouse, camera, scanner, light pen, handwriting input pad, joystick, voice input device, etc. are all input devices.

The mouse is an external input device for the computer. It is a very commonly used computer input device. It is also an indicator for positioning the vertical and horizontal coordinates of the computer display system. It is named after it looks like a mouse. Named after it (Hong Kong and Taiwan make mouse). Its standard name should be "mouse", and its English name is "Mouse". The use of the mouse is to make computer operation easier and faster, replacing the cumbersome instructions of the keyboard.

The mouse can position the cursor on the current screen, and operate the screen elements where the cursor passes through the buttons and wheel device. The ancestor of the mouse appeared in 1968, when American scientist Douglas Englebart made the first mouse in California.

Expand knowledge:

Mouse can be divided into mechanical, opto-mechanical and photoelectric based on its working principle and its internal structure. The mechanical mouse is mainly composed of a rolling ball, a roller and a grating signal sensor. When you drag the mouse, the rolling ball is driven to rotate, and the rolling ball in turn drives the roller to rotate. The grating signal sensor installed at the end of the roller collects the grating signal. The photoelectric pulse signal generated by the sensor reflects the displacement changes of the mouse in the vertical and horizontal directions, and is then processed and converted by the computer program to control the movement of the cursor arrow on the screen.

-

Mechanical mouse

The photoelectric pulse signal generated by the grating signal sensor installed at the end of the roller reflects the displacement changes of the mouse in the vertical and horizontal directions, and then passes through the computer Program processing and transformation to control the movement of the cursor arrow on the screen.

The original mouse only existed as a technical verification product and was not actually mass-produced. After the mouse began to be officially introduced into PCs, the corresponding technology was also innovated. The principle of positioning based on different resistances was completely abandoned and replaced by a "mechanical mouse" with purely digital technology.

Different from the original mouse, the bottom of this mechanical mouse does not have mutually perpendicular flake wheels, but instead uses a small colloidal ball that can roll in four directions. When this small ball rolls, it will drive a pair of rotating shafts to rotate (X axis and Y axis respectively). There is a round decoding wheel at the end of the rotating shaft. The decoding wheel is attached with a metal conductive sheet that is in direct contact with the brush. . When the rotating shaft rotates, these metal conductive pieces and the brushes will come into contact one after another, and there will be two states of "on" or "off". The former corresponds to the binary number "1", and the latter corresponds to the binary number "0". Next, these binary signals are sent to the dedicated chip inside the mouse for analysis and processing and generate corresponding coordinate change signals. As long as the mouse moves on the plane, the small ball will drive the rotating shaft to rotate, which will change the on-off status of the decoding wheel, producing a set of different coordinate offsets, which will be reflected on the screen, that is, the cursor can follow the movement of the mouse. Move and move.

Compared with the original mouse, this mechanical mouse has greatly improved usability, improved response sensitivity and accuracy, and is cheap to manufacture, making it the first widely popular mouse product. However, because it adopts a purely mechanical structure, the X-axis, Y-axis and the ball of the mouse often adhere to some dust and other dirt, resulting in unsatisfactory positioning accuracy. In addition, the brushes and decoding wheels that are in frequent contact are severely worn, directly Affects the service life of the mechanical mouse. After being popular for a period of time, it was replaced by the equally low-cost "optical mouse". The latter is the so-called "mechanical mouse" that is still very common on the market.

-

Optical Mouse

In order to overcome the shortcomings of purely mechanical mice that have low accuracy and easy wear of the mechanical structure, Logitech successfully designed the first optical-mechanical mouse in 1983, which is generally referred to as the "optical-mechanical mouse." The optical-mechanical mouse is an improvement on the purely mechanical mouse, and improves the positioning accuracy of the mouse by introducing optical technology. Like the purely mechanical mouse, the optical-mechanical mouse also has a small rubber roller ball connected to the X and Y axes. The difference is that the optical-mechanical mouse no longer has a round decoding wheel, but two A grating code disc with grating slits, and a light-emitting diode and a photosensitive chip are added. When the mouse moves on the desktop, the rolling ball will drive the two grating code discs on the X and Y axis to rotate, and the light emitted by the X and Y LEDs will illuminate the grating code discs. Since there are grating gaps in the grating code discs, At the right time, the light emitted by the diode can pass through the grid slit and directly illuminate the detection head composed of two photosensitive chips. If a light signal is received, the photosensitive chip will generate a "1" signal. If no light signal is received, it will be set as a signal "0". Next, these signals are sent to a specialized control chip for calculation to generate corresponding coordinate offsets to determine the position of the cursor on the screen.

With the help of this principle, the optical-mechanical mouse greatly exceeds the original purely mechanical mouse in terms of accuracy, reliability, and response sensitivity, and maintains the advantage of low cost. It quickly became popular in the market after its launch. The purely mechanical mouse The mouse was quickly replaced. It can be said that the real mouse era began with the optical mouse, and it continues to this day. Most of the low-end mice on the market are of this type. However, the optical mouse also has its inherent flaws: the small ball at the bottom is not resistant to dirt. After a period of use, the two rotating shafts will be covered with dirt, affecting the passage of light, resulting in problems such as insensitive movement and blocked cursor. Therefore, in order to maintain good performance, the optical mouse requires that the rolling ball and shaft must be thoroughly cleaned every once in a while. In a dusty usage environment, it is even required to be cleaned every two or three days. In addition, as the use time increases, the optical mouse cannot maintain its original good working condition, and the response sensitivity and positioning accuracy will decrease. Durability is less than satisfactory.

As the name suggests, an optical-mechanical mouse is a mouse that combines optoelectronics and mechanics. Based on the mechanical mouse, it replaces the most worn contact brushes and decoding wheels with non-contact LED through-beam optical components. When the ball rolls, the rollers in the X and Y directions drive the code wheel to rotate. There are two sets of light-emitting diodes and photosensitive triodes installed on both sides of the code wheel. The light beam emitted by the LED sometimes shines on the photosensitive triode, and sometimes is blocked. This results in a pulse sequence with two-stage groups with a phase difference of 90°. The number of pulses represents the displacement of the mouse, and the phase represents the direction of mouse movement. Due to the use of non-contact parts, the wear rate is reduced, thereby greatly extending the life of the mouse and increasing the accuracy of the mouse. The appearance of an optical mouse is no different from that of a mechanical mouse, and it is difficult to tell the difference without opening the shell of the mouse.

-

Optical mouse

The optical mouse detects the displacement of the mouse, converts the displacement signal into an electrical pulse signal, and then controls the on-screen movement through program processing and conversion. Cursor arrow movement.

In the same era as the development of the optical-mechanical mouse, a digital optical mouse with no mechanical structure appeared. The original intention of designing this optical mouse is to bring the accuracy of the mouse to a whole new level so that it can fully meet the needs of professional applications. This kind of optical mouse does not have traditional designs such as rolling balls and rotating shafts. Its main components are two light-emitting diodes, a photosensitive chip, a control chip and a reflective plate with a grid (equivalent to a special mouse pad). When working, the photoelectric mouse must move on the reflective plate. The X light-emitting diode and the Y light-emitting diode will respectively emit light and shine on the reflective plate. Then the light will be reflected back by the reflective plate, and then transmitted through the lens assembly and illuminated on the photosensitive chip. The photosensitive chip converts the light signal into a corresponding digital signal and sends it to the positioning chip for special processing, thereby generating X-Y coordinate offset data.

This kind of optical mouse has indeed improved in terms of accuracy, but it has exposed a lot of flaws in subsequent applications. First of all, the optical mouse must rely on the reflector. Its position data is generated entirely based on the grid information in the reflector. If the reflector is dirty or worn, the optical mouse will not be able to determine the position of the cursor. If the reflector is accidentally seriously damaged or lost, the entire mouse will be scrapped. Secondly, using an optical mouse is very inhumane. Its movement direction must be perpendicular to the grid texture on the reflector. It is impossible for the user to quickly move the mouse. The cursor moves directly from the upper left corner to the lower right corner of the screen; thirdly, the cost of an optical mouse is quite high. The price of several hundred yuan is not a big deal today, but in that era people were only willing to pay about 20 yuan for the mouse. In terms of funds, the high price of an optical mouse seems unreasonable. Due to a large number of disadvantages, this kind of optical mouse has not become popular. At best, it has only been used to a certain extent in a few professional drawing situations. However, with the overall popularity of the optical mouse, this kind of optical mouse was quickly replaced by the market. eliminated.

-

Optical Mouse

The optical mouse is an advanced mouse designed by Microsoft. It uses NTELLIEYE technology. There is a small photosensitive head in the small hole at the bottom of the mouse. Facing the photosensitive head is a luminescent tube that emits infrared rays. This luminous tube emits 1500 times per second, and then the photosensitive head emits these 1500 infrared rays. The reflections are fed back to the mouse positioning system to achieve accurate positioning. So, this mouse can move anywhere without any restrictions.

Although the optical mouse failed miserably, the advantages of its all-digital working method, no mechanical structure and high precision have attracted the attention of the industry. If its inherent defects can be overcome, its advantages can be carried forward and a high-precision product can be created. Products with precision, high reliability and durability are completely technically feasible. The first to achieve results in this field were Microsoft and Agilent Technologies. In 1999, Microsoft launched a second-generation optical mouse called "IntelliMouseExplorer". This mouse uses the IntelliEye optical engine jointly developed by Microsoft and Agilent. Because it relies more on optical technology, it is also known as For "optical mouse".

It not only retains the advantages of high precision and no mechanical structure of the optical mouse, but also has high reliability and durability. It does not need to be cleaned during use and can maintain good working condition. It can be used quickly after birth. attracted the attention of the industry. In 2000, Logitech also cooperated with Agilent to launch related products, while Microsoft later conducted independent research and development work and launched the second-generation IntelliEye optical engine at the end of 2001. In this way, optical mice have formed two camps represented by Microsoft and Logitech. Although Agilent Technologies also masters the core technology of optical engines, it is not involved in the manufacturing of mouse products. Instead, it provides optical engine products to third-party mouse manufacturers. , almost all non-Microsoft and Logitech brand mice on the market use its technology.

The structure of the optical mouse is very different from all the above products. It has no rollers at the bottom and does not need a reflective plate to achieve positioning. Its core components are light-emitting diodes, micro cameras, optical engines and control chip. During operation, the light-emitting diode emits light to illuminate the surface of the bottom of the mouse, and at the same time, the miniature camera continuously captures images at certain intervals. The different images generated by the mouse during movement are transmitted to the optical engine for digital processing, and finally the positioning DSP chip in the optical engine analyzes the digital matrix of the generated images. Since two adjacent images always have the same features, by comparing the position change information of these feature points, the movement direction and distance of the mouse can be judged. This analysis result is eventually converted into a coordinate offset to realize the positioning of the cursor. .

For more related knowledge, please visit the FAQ column!

The above is the detailed content of Is the mouse an input device or an output device?. For more information, please follow other related articles on the PHP Chinese website!

Hot AI Tools

Undresser.AI Undress

AI-powered app for creating realistic nude photos

AI Clothes Remover

Online AI tool for removing clothes from photos.

Undress AI Tool

Undress images for free

Clothoff.io

AI clothes remover

AI Hentai Generator

Generate AI Hentai for free.

Hot Article

Hot Tools

Notepad++7.3.1

Easy-to-use and free code editor

SublimeText3 Chinese version

Chinese version, very easy to use

Zend Studio 13.0.1

Powerful PHP integrated development environment

Dreamweaver CS6

Visual web development tools

SublimeText3 Mac version

God-level code editing software (SublimeText3)

Hot Topics

1371

1371

52

52

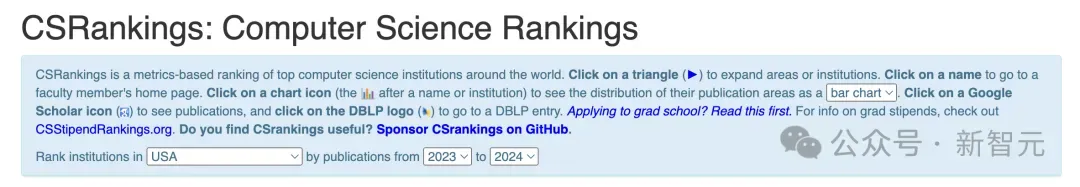

2024 CSRankings National Computer Science Rankings Released! CMU dominates the list, MIT falls out of the top 5

Mar 25, 2024 pm 06:01 PM

2024 CSRankings National Computer Science Rankings Released! CMU dominates the list, MIT falls out of the top 5

Mar 25, 2024 pm 06:01 PM

The 2024CSRankings National Computer Science Major Rankings have just been released! This year, in the ranking of the best CS universities in the United States, Carnegie Mellon University (CMU) ranks among the best in the country and in the field of CS, while the University of Illinois at Urbana-Champaign (UIUC) has been ranked second for six consecutive years. Georgia Tech ranked third. Then, Stanford University, University of California at San Diego, University of Michigan, and University of Washington tied for fourth place in the world. It is worth noting that MIT's ranking fell and fell out of the top five. CSRankings is a global university ranking project in the field of computer science initiated by Professor Emery Berger of the School of Computer and Information Sciences at the University of Massachusetts Amherst. The ranking is based on objective

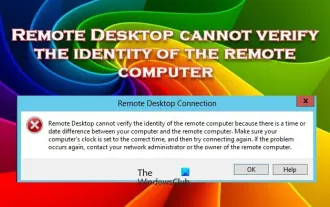

Remote Desktop cannot authenticate the remote computer's identity

Feb 29, 2024 pm 12:30 PM

Remote Desktop cannot authenticate the remote computer's identity

Feb 29, 2024 pm 12:30 PM

Windows Remote Desktop Service allows users to access computers remotely, which is very convenient for people who need to work remotely. However, problems can be encountered when users cannot connect to the remote computer or when Remote Desktop cannot authenticate the computer's identity. This may be caused by network connection issues or certificate verification failure. In this case, the user may need to check the network connection, ensure that the remote computer is online, and try to reconnect. Also, ensuring that the remote computer's authentication options are configured correctly is key to resolving the issue. Such problems with Windows Remote Desktop Services can usually be resolved by carefully checking and adjusting settings. Remote Desktop cannot verify the identity of the remote computer due to a time or date difference. Please make sure your calculations

What is e in computer

Aug 31, 2023 am 09:36 AM

What is e in computer

Aug 31, 2023 am 09:36 AM

The "e" of computer is the scientific notation symbol. The letter "e" is used as the exponent separator in scientific notation, which means "multiplied to the power of 10". In scientific notation, a number is usually written as M × 10^E, where M is a number between 1 and 10 and E represents the exponent.

Fix: Microsoft Teams error code 80090016 Your computer's Trusted Platform module has failed

Apr 19, 2023 pm 09:28 PM

Fix: Microsoft Teams error code 80090016 Your computer's Trusted Platform module has failed

Apr 19, 2023 pm 09:28 PM

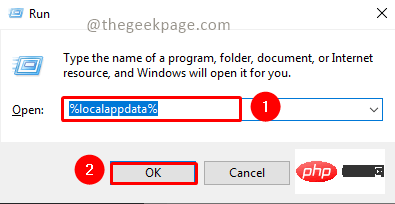

<p>MSTeams is the trusted platform to communicate, chat or call with teammates and colleagues. Error code 80090016 on MSTeams and the message <strong>Your computer's Trusted Platform Module has failed</strong> may cause difficulty logging in. The app will not allow you to log in until the error code is resolved. If you encounter such messages while opening MS Teams or any other Microsoft application, then this article can guide you to resolve the issue. </p><h2&

What does computer cu mean?

Aug 15, 2023 am 09:58 AM

What does computer cu mean?

Aug 15, 2023 am 09:58 AM

The meaning of cu in a computer depends on the context: 1. Control Unit, in the central processor of a computer, CU is the component responsible for coordinating and controlling the entire computing process; 2. Compute Unit, in a graphics processor or other accelerated processor, CU is the basic unit for processing parallel computing tasks.

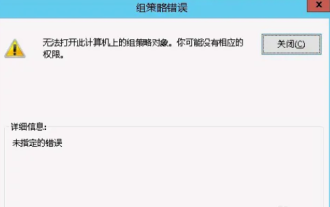

Unable to open the Group Policy object on this computer

Feb 07, 2024 pm 02:00 PM

Unable to open the Group Policy object on this computer

Feb 07, 2024 pm 02:00 PM

Occasionally, the operating system may malfunction when using a computer. The problem I encountered today was that when accessing gpedit.msc, the system prompted that the Group Policy object could not be opened because the correct permissions may be lacking. The Group Policy object on this computer could not be opened. Solution: 1. When accessing gpedit.msc, the system prompts that the Group Policy object on this computer cannot be opened because of lack of permissions. Details: The system cannot locate the path specified. 2. After the user clicks the close button, the following error window pops up. 3. Check the log records immediately and combine the recorded information to find that the problem lies in the C:\Windows\System32\GroupPolicy\Machine\registry.pol file

What should I do if steam cannot connect to the remote computer?

Mar 01, 2023 pm 02:20 PM

What should I do if steam cannot connect to the remote computer?

Mar 01, 2023 pm 02:20 PM

Solution to the problem that steam cannot connect to the remote computer: 1. In the game platform, click the "steam" option in the upper left corner; 2. Open the menu and select the "Settings" option; 3. Select the "Remote Play" option; 4. Check Activate the "Remote Play" function and click the "OK" button.

Unable to copy data from remote desktop to local computer

Feb 19, 2024 pm 04:12 PM

Unable to copy data from remote desktop to local computer

Feb 19, 2024 pm 04:12 PM

If you have problems copying data from a remote desktop to your local computer, this article can help you resolve it. Remote desktop technology allows multiple users to access virtual desktops on a central server, providing data protection and application management. This helps ensure data security and enables companies to manage their applications more efficiently. Users may face challenges while using Remote Desktop, one of which is the inability to copy data from the Remote Desktop to the local computer. This may be caused by different factors. Therefore, this article will provide guidance on resolving this issue. Why can't I copy from the remote desktop to my local computer? When you copy a file on your computer, it is temporarily stored in a location called the clipboard. If you cannot use this method to copy data from the remote desktop to your local computer