What does cmp device mean?

cmp equipment is chemical mechanical planarization equipment; cmp is the abbreviation of "Chemical Mechanical Polishing". It is one of the key technologies for semiconductor wafer surface processing and is currently the most common semiconductor material surface planarization technology. Its work The process is that the polishing head presses the surface of the wafer to be polished against the rough polishing pad, and achieves global planarization with the help of polishing liquid corrosion, particle friction, polishing pad friction and other couplings.

The operating environment of this tutorial: Windows 10 system, DELL G3 computer.

What does cmp equipment mean

CMP equipment, the full name of chemical mechanical planarization (CMP) equipment, is one of the key equipment for semiconductor wafer surface treatment and is currently the most common Semiconductor material surface planarization technology.

CMP stands for Chemical Mechanical Polishing, which is one of the key technologies for surface processing of semiconductor wafers. Chemical mechanical polishing technology is used many times in the manufacturing process of single crystal silicon wafers and in the first half of the process. Compared with the previously commonly used mechanical polishing, chemical mechanical polishing can make the surface of the silicon wafer flatter, and also has the advantages of low processing cost and simple processing method, so it has become the most common surface smoothing technology for semiconductor materials.

Since integrated circuit components currently generally use multi-layer three-dimensional wiring, the front-end process of integrated circuit manufacturing requires multi-layer circulation. During this process, the wafer surface needs to be planarized through the CMP process. Integrated circuit manufacturing is the main application scenario of CMP equipment, which is repeatedly used after film deposition and before photolithography.

CMP equipment is the only way to flatten the wafer. Its working process is: the polishing head presses the surface of the wafer to be polished against the rough polishing pad, and uses the polishing liquid corrosion, particle friction, and polishing pad to Friction and other couplings achieve global flattening. The polishing disk drives the polishing pad to rotate, and the advanced end point detection system rubs different materials and thicknesses to achieve real-time thickness measurement with a resolution of 3-10nm to prevent over-polishing. The more critical technology lies in the polishing head that can exert global zoned pressure. It can achieve ultra-precise and controllable unidirectional pressure on multiple annular areas around the wafer in a limited space, so that it can respond to the film thickness measured by the polishing disk. The data adjusts the pressure to control the polishing shape of the wafer, so that the polished wafer surface reaches ultra-high flatness and the surface roughness is less than 0.5nm, which is equivalent to one hundred thousandth of a human hair.

Unlike semiconductor equipment such as photolithography machines and etching machines, CMP equipment is less affected by Moore's Law and does not have a technology iteration cycle over a long period of time. Application There are no significant differences between 28nm and 14nm CMP devices, just optimization of specific module technologies. However, as the CMP process continues to advance from 14nm to 7nm, 5nm, and 3nm advanced processes, CMP technology will continue to develop in the direction of refined polishing head partitioning, intelligent process control, and multi-energy combination of cleaning units.

Patents are a blessing for forerunners and a "curse" for those who come after. After 2013, the number of CMP patent applications has grown slowly, while the number of post-CMP cleaning patent applications has been in decline. The overall number of global CMP patent applications remains stable, reflecting that there are currently no major technological innovations in global CMP technology, and latecomers must face strong patent barriers if they want to catch up.

For more related knowledge, please visit the FAQ column!

The above is the detailed content of What does cmp device mean?. For more information, please follow other related articles on the PHP Chinese website!

Hot AI Tools

Undresser.AI Undress

AI-powered app for creating realistic nude photos

AI Clothes Remover

Online AI tool for removing clothes from photos.

Undress AI Tool

Undress images for free

Clothoff.io

AI clothes remover

Video Face Swap

Swap faces in any video effortlessly with our completely free AI face swap tool!

Hot Article

Hot Tools

Notepad++7.3.1

Easy-to-use and free code editor

SublimeText3 Chinese version

Chinese version, very easy to use

Zend Studio 13.0.1

Powerful PHP integrated development environment

Dreamweaver CS6

Visual web development tools

SublimeText3 Mac version

God-level code editing software (SublimeText3)

Hot Topics

1386

1386

52

52

Error code 801c03ed: How to fix it on Windows 11

Oct 04, 2023 pm 06:05 PM

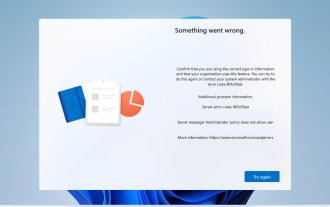

Error code 801c03ed: How to fix it on Windows 11

Oct 04, 2023 pm 06:05 PM

Error 801c03ed is usually accompanied by the following message: Administrator policy does not allow this user to join the device. This error message will prevent you from installing Windows and joining a network, thereby preventing you from using your computer, so it is important to resolve this issue as soon as possible. What is error code 801c03ed? This is a Windows installation error that occurs due to the following reason: Azure setup does not allow new users to join. Device objects are not enabled on Azure. Hardware hash failure in Azure panel. How to fix error code 03c11ed on Windows 801? 1. Check Intune settings Log in to Azure portal. Navigate to Devices and select Device Settings. Change "Users can

How to fix device disabled (error code 22) in Windows 10/11

Aug 04, 2023 pm 03:17 PM

How to fix device disabled (error code 22) in Windows 10/11

Aug 04, 2023 pm 03:17 PM

Is the "This device is disabled" code 22 error in Device Manager preventing you from using a new or old device on your PC? Don’t worry because we are here to help you solve this problem. A code 22 error means the device has been manually disabled and sometimes re-enabling it does not help. Whatever the cause, here are 10 ways to fix the “This device is disabled” code 10 error on Windows 22/PC and make that hardware work again. 1. Unplug and replug new hardware New hardware you plug into your PC may start working again after a quick removal and reinstallation. So if it's a device plugged in via USB, go ahead and unplug it. Then, wait a few seconds and plug it back in. Now, check if the device is showing up in device manager

8 Ways to Reinstall Safari on iPhone

Sep 16, 2023 am 11:17 AM

8 Ways to Reinstall Safari on iPhone

Sep 16, 2023 am 11:17 AM

Web browsing is an essential function of mobile devices, and browsers facilitate it effectively. These browsers also support the installation of content blockers and other tools to personalize your browsing experience. Apple's iOS platform uses Safari as its default browser. In rare cases, you may find that Safari browser is missing from your device. If you encounter this situation, the following steps will guide you on how to restore it. Can you reinstall Safari on iPhone? Safari is a built-in application on iOS devices and cannot be deleted or uninstalled due to its protected system status. If the app seems to be missing from your device, you may be dealing with an error, or the app may be hidden for various reasons.

What device is prru?

Apr 14, 2023 pm 04:59 PM

What device is prru?

Apr 14, 2023 pm 04:59 PM

PRRU refers to pico base station equipment, which is an active device. It is a small, low-power, low-power indoor coverage radio frequency unit, that is, an indoor base station. The PRRU has the functions of a receiver and a transmitter, that is, it converts the digital signal (first converted into an intermediate frequency signal) into a radio frequency signal at the remote end, and then amplifies and transmits it; or it receives the radio frequency signal received by the antenna and converts it into a digital signal. and then passed to the baseband processing unit.

Fix: The driver cannot be loaded on this device in Windows 11

Apr 15, 2023 pm 08:22 PM

Fix: The driver cannot be loaded on this device in Windows 11

Apr 15, 2023 pm 08:22 PM

Drivers are key software that facilitates command relay between the operating system and the corresponding device. But what if you encounter Adrivercannotloadonthisdevice error in Windows 11? You will see this error message when booting the operating system, and its effects may or may not be noticeable initially, depending on the affected drivers. However, over time, the driver may stop functioning with the corresponding device. Therefore, you must troubleshoot the error. Also, in most cases, the faulty driver will be listed in the error box, making it easier for you to continue. How to fix A driver could not be loaded on this device error in Windows 11? 1.

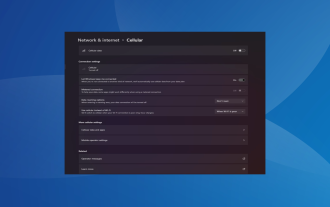

How to re-enable cellular options on Windows 11

Sep 18, 2023 am 10:29 AM

How to re-enable cellular options on Windows 11

Sep 18, 2023 am 10:29 AM

The laptop's cellular capabilities generally work fine, and users can insert a SIM card or use an eSIM. But recently, some people have reported that the cellular option is missing in Windows 11. Regardless of whether they restart the PC or unplug and reinsert the SIM card, the cellular option does not appear in Windows 11. Keep in mind that some Windows 10 users are also facing the same issue. Why don't my mobile network settings show up on Windows 11? Outdated, incompatible, corrupt or problematic drivers Cellular data network operators are facing issues Network adapter is disabled eSIM profile is not working or corrupt How to enable missing cellular option again on Windows 11? Before we start using a slightly complex

How to stream video or mirror your iPhone or iPad screen using AirPlay

Jul 14, 2023 pm 07:53 PM

How to stream video or mirror your iPhone or iPad screen using AirPlay

Jul 14, 2023 pm 07:53 PM

This quick guide will show you how to use AirPlay, Apple's innovative wireless streaming feature to easily share and display content. Allows you to use Wi-Fi to connect your iPhone or iPad to AirPlay-compatible Apple TVs, smart TVs, speakers, and Macs, as well as certain third-party speakers and smart TVs, for seamless data transfer. AirPlay operates on a peer-to-peer basis, connecting your Apple devices through the local network. It uses a combination of technologies, including Real-Time Transport Protocol (RTP) for streaming audio and video and Bonjour for device discovery. Simply put, when you use AirPlay, your device sends a stream of data and then

Please update your device settings to accept media transfers

Feb 19, 2024 pm 12:24 PM

Please update your device settings to accept media transfers

Feb 19, 2024 pm 12:24 PM

We will show you how to fix media transfer error when connecting your phone to PC via USB cable. When you try to import photos and videos from your phone to your computer, you may encounter a "Please update your device's settings to accept media transfers" error message displayed by the Photos app. Please update your device settings to accept media transfers Update your device settings to allow media transfers to resolve the error message. Restart your two devices Use different USB cables Check your Android phone settings Install the MTP USB device driver Use other methods to transfer your photos and videos Let’s get started. 1] Restart both devices It is recommended that you first try to restart your devices, including computers and phones, when you encounter a temporary failure. Heavy