What software is adams

adams refers to "automatic analysis of mechanical system dynamics". It is a virtual prototype analysis software developed by American Mechanical Power Company; it uses an interactive graphical environment and parts library, constraint library, and force library to create A fully parameterized geometric model of the mechanical system. Its solver uses the Lagrange equation method in the multi-rigid body system dynamics theory to establish the system dynamics equations, conduct statics, kinematics and dynamics analysis of the virtual mechanical system, and output Displacement, velocity, acceleration and reaction force curves.

The operating environment of this tutorial: Windows 7 system, Dell G3 computer.

ADAMS stands for Automatic Dynamic Analysis of Mechanical Systems. This software is a virtual prototype developed by Mechanical Dynamics Inc. (now merged into MSC Corporation of the United States). Analyzing Software. ADAMS has been adopted by hundreds of major manufacturers in various industries around the world. According to statistics on the international market share of mechanical system dynamic simulation analysis software in 1999, ADAMS software sales totaled nearly 80 million US dollars, accounting for 51% of the market share. It has now been merged into the American MSC company.

ADAMS software uses an interactive graphical environment and parts library, constraint library, and force library to create a fully parameterized geometric model of the mechanical system. Its solver uses the Lagrange equation in the multi-rigid body system dynamics theory. Method, establish system dynamics equations, conduct statics, kinematics and dynamic analysis of the virtual mechanical system, and output displacement, velocity, acceleration and reaction force curves. Simulations in ADAMS software can be used to predict mechanical system performance, range of motion, collision detection, peak loads, and calculation of finite element input loads.

On the one hand, ADAMS is an application software for virtual prototype analysis. Users can use this software to conduct statics, kinematics and dynamics analysis of virtual mechanical systems very conveniently. On the other hand, it is a virtual prototype analysis and development tool. Its open program structure and multiple interfaces can become a secondary development tool platform for users in special industries to conduct special types of virtual prototype analysis. ADAMS software has two operating system versions: UNIX version and Windows NT/2000 version. This introduction will be based on the Windows 2000 version of ADAMS l2.0.

Software module

ADAMS software consists of five types of modules: basic module, expansion module, interface module, professional field module and toolbox. Users can not only use general modules to simulate general mechanical systems, but also use special modules to conduct fast and effective modeling and simulation analysis for problems in specific industrial application fields.

The modules and toolboxes included in the ADAMS software are as follows:

Basic module user interface module ADAMS/View

Solver module ADAMS/Solver

Post-processing Module ADAMS/PostProcessor

Extension module hydraulic system module ADAMS/Hydraulics

Vibration analysis module ADAMS/Vibration

Linearization analysis module ADAMS/Linear

High speed Animation module ADAMS/Animation

Experimental design and analysis module ADAMS/Insight

Durability analysis module ADAMS/Durability

Digital assembly playback module ADAMS/DMU Replay

Interface module flexible analysis module ADAMS/Flex

Control module ADAMS/Controls

Graphic interface module ADAMS/Exchange

CATIA professional interface module CAT/ADAMS

Pro/E interface module Mechanical/Pro

Professional field module Car module ADAMS/Car

Suspension design software package Suspension Design

Conceptual suspension module CSM

Driver module ADAMS/Driver

Powertrain module ADAMS/Driveline

Tire module ADAMS/Tire

Flexible ring tire module FTire Module

Flexible body generator module ADAMS/FBG

Empirical dynamics model EDM

Engine design module ADAMS/Engine

Valve train module ADAMS/Engine Valvetrain

Timing chain module ADAMS/Engine Chain

Accessory Drive Module

Railway vehicle module ADAMS/Rail

FORD Automobile Company special car module ADAMS/Pre (Now renamed Chassis)

Toolbox Software Development Kit ADAMS/SDK

Virtual Test ToolboxVirtual Test Lab

Virtual Experiment Modal Analysis ToolboxVirtual Experiment Modal Analysis

Leafspring Toolkit

ADAMS/Landing Gear

Track/Wheeled Vehicle ToolkitTracked/Wheeled Vehicle

Gear Transmission ToolboxADAMS/Gear Tool

Comprehensive features

1. New online help system and PDF format files for easy printing

In MD Adams, MSC.Software has introduced a new electronic online help system. The entire help system is available to users of MD Adams and MD Adams/Car. In the table of contents of the help system, it is organized according to modules to make it easier to find and search information.

Added help for the command language in MD Adams/View, and added a new theoretical manual for the MD Adams/Vibration module.

To facilitate printing, the help document provides PDF format of all help documents.

2. The output linear model can be used for further vibration performance analysis in NASTRAN

A new feature of MD Adams/Vibration is the Adams2Nastran function, which can output linear models for further vibration performance analysis in NASTRAN. This function encapsulates the linearized ADAMS model into Nastran's DMIG input form. Once the output is completed, users can use NASTRAN's powerful frequency response analysis function to conduct accurate NVH analysis of the system and system response analysis in the higher frequency domain.

3. New analysis method for handling spheres in 3D contact analysis

When there is 3D sphere contact collision in the model, in order to obtain more accurate results, the contact is strengthened Algorithm for calculation, i.e. using real geometry to represent the sphere. Compared with the old method of representing the surface of a sphere with facets, the solution speed of this algorithm is significantly faster. For example, the ball bearing model is solved 3.1 times faster.

Another benefit of this algorithm is the improved accuracy of contact load calculations. The graph shows the difference in contact loads obtained by the old algorithm (black curve) and the new algorithm (red curve).

4. Calculation of time-varying cumulative mass during the simulation process

A new practical subroutine has been developed in the new version, which can automatically calculate the time-varying cumulative mass of the system during the simulation process.

The new solver can complete the calculation of the mass of multi-body systems, including rigid bodies and elastic bodies.

5. Curve drawing of stress and strain results of frequency response simulation nodes

The new version of MD Adams supports drawing the result curve of stress and strain on elastic bodies caused by forced load excitation load input. . Using this feature, analysts can quickly conduct "what-if" studies while considering the impact of the multi-body dynamic characteristics and structure of the system.

6. MD Adams/Car Mechatronics automotive electromechanical module

MD Adams/Car Mechatronics (car electromechanical module) is a new module that greatly enhances Adams/Car and Adams/Controls integration. The purpose of the new module is the implementation of a standardized control system under the Car model.

Using the new electromechanical module, you can easily simulate the impact of parameters on the performance of your vehicle's control system, turning the controller on/off with a simple toggle on the controller.

The signal controller, as part of the electromechanical module, can connect the control system and the mechanical system when the entire system is assembled.

7. C Solver supports Adams/Car

Adams/Car models can be solved using C Solver. Users can use the new HHT integrator to improve the solving speed. The MD Adams/Tire and MD Adams/SmartDriver modules also support the new C Solver.

The new C Solver provides the function of analyzing partial differential equations, so it is more accurate and more stable. It also supports the general state equation (GSE) based on the transmission system, and improves the model including elastomers and leaf springs.

8. More accurate dynamic suspension analysis

MD Adams has the function to use the dynamic suspension test bench to complete a more realistic dynamic suspension analysis of the suspension model. This new feature improves the accuracy of simulations by taking into account the dynamic effects of suspension motion.

Users can also use RPC format files as motion drivers, which is crucial for durability performance analysis of suspension systems and their components.

9. New test bench for tire analysis

The tire test bench enables faster comparison of multiple tire models. Various curve diagrams required for comparison of tire characteristics can be automatically generated for different tire models. This highly automated analysis function interface helps you quickly analyze and compare the quality of various tire models and tire databases.

Adams Golf Founded in 1987, Adams Golf, Inc. is committed to designing, assembling and selling high-quality, innovative golf clubs. Adams Golf has always been dedicated to the research and development of golf equipment and related accessories, and continues to innovate on the basis of multiple product series to provide consumers with more choices.

For more related knowledge, please visit the FAQ column!

The above is the detailed content of What software is adams. For more information, please follow other related articles on the PHP Chinese website!

Hot AI Tools

Undresser.AI Undress

AI-powered app for creating realistic nude photos

AI Clothes Remover

Online AI tool for removing clothes from photos.

Undress AI Tool

Undress images for free

Clothoff.io

AI clothes remover

AI Hentai Generator

Generate AI Hentai for free.

Hot Article

Hot Tools

Notepad++7.3.1

Easy-to-use and free code editor

SublimeText3 Chinese version

Chinese version, very easy to use

Zend Studio 13.0.1

Powerful PHP integrated development environment

Dreamweaver CS6

Visual web development tools

SublimeText3 Mac version

God-level code editing software (SublimeText3)

Hot Topics

1385

1385

52

52

What software is bonjour and can it be uninstalled?

Feb 20, 2024 am 09:33 AM

What software is bonjour and can it be uninstalled?

Feb 20, 2024 am 09:33 AM

Title: Explore the Bonjour software and how to uninstall it Abstract: This article will introduce the functions, scope of use and how to uninstall the Bonjour software. At the same time, it will also be explained how to use other tools to replace Bonjour to meet the needs of users. Introduction: Bonjour is a common software in the field of computer and network technology. Although this may be unfamiliar to some users, it can be very useful in some specific situations. If you happen to have Bonjour software installed but now want to uninstall it, then

What to do if WPS Office cannot open the PPT file - What to do if WPS Office cannot open the PPT file

Mar 04, 2024 am 11:40 AM

What to do if WPS Office cannot open the PPT file - What to do if WPS Office cannot open the PPT file

Mar 04, 2024 am 11:40 AM

Recently, many friends have asked me what to do if WPSOffice cannot open PPT files. Next, let us learn how to solve the problem of WPSOffice not being able to open PPT files. I hope it can help everyone. 1. First open WPSOffice and enter the homepage, as shown in the figure below. 2. Then enter the keyword "document repair" in the search bar above, and then click to open the document repair tool, as shown in the figure below. 3. Then import the PPT file for repair, as shown in the figure below.

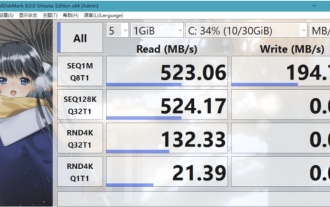

What software is crystaldiskmark? -How to use crystaldiskmark?

Mar 18, 2024 pm 02:58 PM

What software is crystaldiskmark? -How to use crystaldiskmark?

Mar 18, 2024 pm 02:58 PM

CrystalDiskMark is a small HDD benchmark tool for hard drives that quickly measures sequential and random read/write speeds. Next, let the editor introduce CrystalDiskMark to you and how to use crystaldiskmark~ 1. Introduction to CrystalDiskMark CrystalDiskMark is a widely used disk performance testing tool used to evaluate the read and write speed and performance of mechanical hard drives and solid-state drives (SSD). Random I/O performance. It is a free Windows application and provides a user-friendly interface and various test modes to evaluate different aspects of hard drive performance and is widely used in hardware reviews

![Corsair iCUE software not detecting RAM [Fixed]](https://img.php.cn/upload/article/000/465/014/170831448976874.png?x-oss-process=image/resize,m_fill,h_207,w_330) Corsair iCUE software not detecting RAM [Fixed]

Feb 19, 2024 am 11:48 AM

Corsair iCUE software not detecting RAM [Fixed]

Feb 19, 2024 am 11:48 AM

This article will explore what users can do when the CorsairiCUE software does not recognize the RAM in a Windows system. Although the CorsairiCUE software is designed to let users control their computer's RGB lighting, some users have found that the software does not function properly, resulting in an inability to detect RAM modules. Why doesn't ICUE pick up my memory? The main reason why ICUE cannot correctly identify RAM is usually related to background software conflicts. In addition, incorrect SPD write settings may also cause this problem. Fixed issue with CorsairIcue software not detecting RAM If CorsairIcue software is not detecting RAM on your Windows computer, please use the following suggestions.

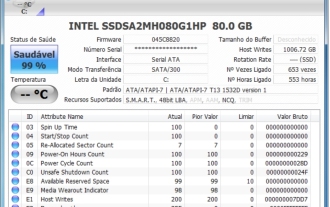

CrystalDiskinfo usage tutorial-What software is CrystalDiskinfo?

Mar 18, 2024 pm 04:50 PM

CrystalDiskinfo usage tutorial-What software is CrystalDiskinfo?

Mar 18, 2024 pm 04:50 PM

CrystalDiskInfo is a software used to check computer hardware devices. In this software, we can check our own computer hardware, such as reading speed, transmission mode, interface, etc.! So in addition to these functions, how to use CrystalDiskInfo and what exactly is CrystalDiskInfo? Let me sort it out for you! 1. The Origin of CrystalDiskInfo As one of the three major components of a computer host, a solid-state drive is the storage medium of a computer and is responsible for computer data storage. A good solid-state drive can speed up file reading and affect consumer experience. When consumers receive new devices, they can use third-party software or other SSDs to

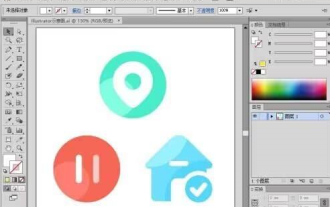

How to set the keyboard increment in Adobe Illustrator CS6 - How to set the keyboard increment in Adobe Illustrator CS6

Mar 04, 2024 pm 06:04 PM

How to set the keyboard increment in Adobe Illustrator CS6 - How to set the keyboard increment in Adobe Illustrator CS6

Mar 04, 2024 pm 06:04 PM

Many users are using the Adobe Illustrator CS6 software in their offices, so do you know how to set the keyboard increment in Adobe Illustrator CS6? Then, the editor will bring you the method of setting the keyboard increment in Adobe Illustrator CS6. Interested users can take a look below. Step 1: Start Adobe Illustrator CS6 software, as shown in the figure below. Step 2: In the menu bar, click the [Edit] → [Preferences] → [General] command in sequence. Step 3: The [Keyboard Increment] dialog box pops up, enter the required number in the [Keyboard Increment] text box, and finally click the [OK] button. Step 4: Use the shortcut key [Ctrl]

What kind of software is bonjour? Is it useful?

Feb 22, 2024 pm 08:39 PM

What kind of software is bonjour? Is it useful?

Feb 22, 2024 pm 08:39 PM

Bonjour is a network protocol and software launched by Apple for discovering and configuring network services within a local area network. Its main role is to automatically discover and communicate between devices connected in the same network. Bonjour was first introduced in the MacOSX10.2 version in 2002, and is now installed and enabled by default in Apple's operating system. Since then, Apple has opened up Bonjour's technology to other manufacturers, so many other operating systems and devices can also support Bonjour.

How to resolve an incompatible software attempt to load with Edge?

Mar 15, 2024 pm 01:34 PM

How to resolve an incompatible software attempt to load with Edge?

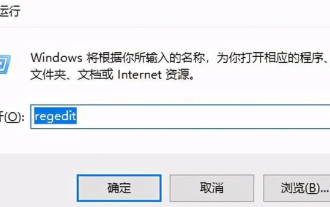

Mar 15, 2024 pm 01:34 PM

When we use the Edge browser, sometimes incompatible software attempts to be loaded together, so what is going on? Let this site carefully introduce to users how to solve the problem of trying to load incompatible software with Edge. How to solve an incompatible software trying to load with Edge Solution 1: Search IE in the start menu and access it directly with IE. Solution 2: Note: Modifying the registry may cause system failure, so operate with caution. Modify registry parameters. 1. Enter regedit during operation. 2. Find the path\HKEY_LOCAL_MACHINE\SOFTWARE\Policies\Micros