What is vcsel chip

vcsel generally refers to a vertical cavity surface emitting laser. It is a semiconductor in which the laser is emitted perpendicularly to the top surface. It is different from the edge-emitting laser that generally uses a cut independent chip process and the laser is emitted from the edge. ; Because VCSELs emit laser light from the top surface of the integrated circuit, they can be tested directly on the chip before being separated into individual entities; this can save the cost and use of equipment in the semiconductor manufacturing process; this also allows the production of VCSELs It is no longer just one-dimensional, but can be a two-dimensional arrangement.

#The operating environment of this tutorial: Windows 7 system, Dell G3 computer.

What is the vcsel chip?

vcsel (vcsel) generally refers to vertical cavity surface emitting laser

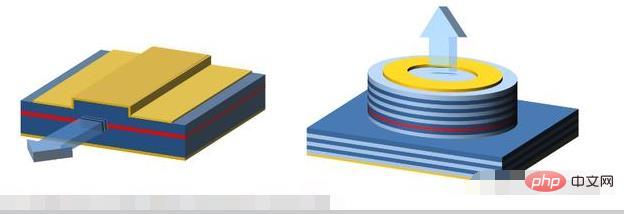

Vertical-Cavity Surface-Emitting Laser (VCSEL for short, also translated as vertical resonant cavity surface emitting laser Type laser) is a semiconductor in which the laser light is emitted perpendicularly to the top surface, which is different from the edge-emitting laser that generally uses a cut independent chip process and the laser light is emitted from the edge.

In the production process, VCSEL has many advantages over edge-emitting lasers. Edge-emitting lasers need to be tested after production is completed. If an edge-fired laser fails to operate, either due to poor contact or poor quality material growth, processing time in the fabrication process and material processing is wasted. However, VCSEL can test its quality and solve problems during any manufacturing process. Because the laser of VCSEL is emitted perpendicularly to the reaction area, as opposed to the edge-emitting laser which is emitted parallel to the reaction area, tens of thousands of VCSELs can be used at the same time. A three-inch gallium arsenic chip was processed. In addition, even though the VCSEL manufacturing process requires more labor and finer materials, the production results are controllable and more predictable.

Features

Because VCSELs emit laser light from the top surface of the integrated circuit, they can be directly on the chip before being segmented into separate individuals. test. This can save the cost and use of equipment in the semiconductor manufacturing process. This also allows the production of VCSELs to be no longer just one-dimensional, but can be arranged in two dimensions.

The larger VCSEL output aperture produces a lower divergence angle of the output beam compared to most edge-emitting lasers, and makes fiber wiring more efficient.

Compared with most edge-emitting lasers, a highly reflective mirror reduces the gate current of the VCSEL, resulting in low power consumption. However, so far, VESELs emit less energy than edge-emitting lasers. The lower gate current also allows the VCSEL to have high intrinsic adjustment bandwidth.

The wavelength of VCSEL in the acquisition band of the reaction zone can be changed by adjusting the thickness of the reflective layer.

The emitted light of early VCSELs was longitudinal multi-mode or filament mode, while today's VCSELs are mostly single-mode.

For more related knowledge, please visit the FAQ column!

The above is the detailed content of What is vcsel chip. For more information, please follow other related articles on the PHP Chinese website!

Hot AI Tools

Undresser.AI Undress

AI-powered app for creating realistic nude photos

AI Clothes Remover

Online AI tool for removing clothes from photos.

Undress AI Tool

Undress images for free

Clothoff.io

AI clothes remover

AI Hentai Generator

Generate AI Hentai for free.

Hot Article

Hot Tools

Notepad++7.3.1

Easy-to-use and free code editor

SublimeText3 Chinese version

Chinese version, very easy to use

Zend Studio 13.0.1

Powerful PHP integrated development environment

Dreamweaver CS6

Visual web development tools

SublimeText3 Mac version

God-level code editing software (SublimeText3)

Hot Topics

1378

1378

52

52