Can the CPU not be coated with silicone grease?

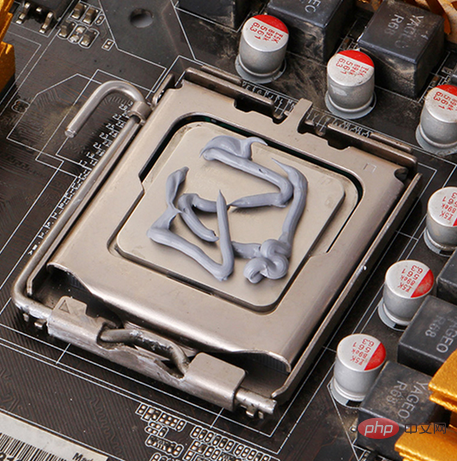

Can't. Silicone grease is used to fill the gap and reduce the thermal resistance between the processor and the radiator; without silicone grease, the temperature of the CPU will rise rapidly. The top cover of the CPU and the bottom of the radiator are made of metal, and no matter how perfect the manufacturing process is, their surfaces cannot be guaranteed to be absolutely flat and smooth, which will leave tiny gaps when the two are in direct contact; Because of the existence of these gaps, there will be a small amount of air between the processor and the radiator base, and the air will seriously affect the thermal conductivity efficiency. Therefore, we need to fill these gaps with silicone grease.

The operating environment of this tutorial: Windows 7 system, Dell G3 computer.

CPU cannot be coated with silicone grease.

Silicone grease is used to fill the gaps and reduce the thermal resistance between the processor and the heat sink. Silicone grease only needs to be applied evenly in a thin layer. Too much or too little will affect the heat dissipation effect.

Without silicone grease, the temperature of the CPU will rise rapidly. Thermal silicone grease plays the role of accelerating heat conduction, conducting heat as a medium, increasing the contact area and filling the pits in the CPU iron cover and the middle of the radiator.

We know that the top cover of the processor and the bottom of the radiator are made of metal (usually aluminum alloy), and no matter how perfect the manufacturing process is, it cannot It can ensure that their surfaces are absolutely flat and smooth, which will leave a tiny gap when the two are in direct contact. In addition, if the player does not install the buckle flat when installing the radiator, it will also cause the bottom of the radiator to warp. There is a gap (a small gap may not have a big impact. If the radiator base is severely crooked, it must be reinstalled).

It is precisely because of these gaps that there will be a small amount of air between the processor and the radiator base, and the air will seriously affect the thermal conductivity efficiency. Therefore, we need to use a filler to fill these gaps, and silicone grease is the most cost-effective and applicable choice. However, don’t think that the more silicone grease you apply, the better. In fact, the thermal conductivity coefficient (W/m·K, also called thermal conductivity) of silicone grease is between 0.8 and 8, which is similar to the thermal conductivity coefficient of copper 377. The ratio is very different, so it can really only be used to fill gaps. Applying too much will become a burden for heat dissipation.

Therefore, it is not possible to apply silicone grease to the CPU. This is because it is for better heat dissipation of the CPU.

Expand knowledge:

Thermal conductive silicone grease is commonly known as thermal paste. Thermal conductive silicone grease uses organic silicone as the main raw material, and is added with The thermally conductive silicone grease compound made of materials with excellent thermal conductivity is used for heat conduction and heat dissipation of electronic components such as power amplifiers, transistors, electron tubes, and CPUs, thereby ensuring the electrical performance of electronic instruments, meters, etc. Stablize.

CPU thermal silicone grease is refined from polymer materials such as organic silica gel body, CPU thermal conductive materials, fillers and other polymer materials. It is mainly used as an accessory to dissipate heat for computer CPUs.

Application scope of CPU thermal grease:

Thermal grease is a kind of material used to fill the gap between the CPU and the heat sink. This material is also called the thermal interface. Material. Its function is to conduct the heat emitted by the CPU to the heat sink to keep the CPU temperature at a stable level, prevent the CPU from being damaged due to poor heat dissipation, and extend the service life.

In heat dissipation and thermal conduction applications, even two planes with very smooth surfaces will have gaps when they contact each other. The air in these gaps is a poor conductor of heat and will hinder the conduction of heat to the heat sink. . Thermal conductive silicone grease is a material that can fill these gaps and make heat conduction smoother and faster.

There are many types of silicone grease on the market, and different parameters and physical properties determine different uses. For example, some are suitable for CPU heat conduction, some are suitable for memory heat conduction, and some are suitable for power supply heat conduction.

The liquid part of thermal silicone grease is composed of silica gel and silicone oil. Most products on the market use dimethyl silicone oil as raw material, and the boiling point of dimethyl silicone oil is between 140°C and 180°C. In between, it is easy to volatilize, oil leakage occurs, and traces of grease will be left on the circuit board. The phenomenon of grease detachment will make customers feel that the silicone grease has dried.

Thermal conductive silicone grease has both excellent electrical insulation and excellent thermal conductivity.

It also has low oil separation (tending to zero), high and low temperature resistance, water resistance, ozone resistance, Resistant to weathering. And it almost never solidifies, and can maintain the grease state during use for a long time at temperatures of -50°C to 230°C. It is an ideal gap-filling thermal conductive medium for electronic components.

For more related knowledge, please visit the

FAQThe above is the detailed content of Can the CPU not be coated with silicone grease?. For more information, please follow other related articles on the PHP Chinese website!

Hot AI Tools

Undresser.AI Undress

AI-powered app for creating realistic nude photos

AI Clothes Remover

Online AI tool for removing clothes from photos.

Undress AI Tool

Undress images for free

Clothoff.io

AI clothes remover

AI Hentai Generator

Generate AI Hentai for free.

Hot Article

Hot Tools

Notepad++7.3.1

Easy-to-use and free code editor

SublimeText3 Chinese version

Chinese version, very easy to use

Zend Studio 13.0.1

Powerful PHP integrated development environment

Dreamweaver CS6

Visual web development tools

SublimeText3 Mac version

God-level code editing software (SublimeText3)

Hot Topics

1385

1385

52

52

What should the CPU utilization be when gaming?

Feb 19, 2024 am 11:21 AM

What should the CPU utilization be when gaming?

Feb 19, 2024 am 11:21 AM

It's common for games to slow down your computer because they consume a lot of resources. It's crucial to understand your CPU usage when gaming so you can avoid overloading it. Therefore, keeping track of appropriate CPU usage is key to keeping your gaming experience smooth. In this article, we'll look at the appropriate CPU usage you should achieve while your game is running. CPU utilization during gaming CPU utilization is an important indicator of processor workload and depends on the performance specifications of the CPU. More powerful CPUs generally have higher usage. A CPU with more cores and threads can improve the overall performance of your system. Multi-threading support helps unleash the full potential of your CPU. In games, CPU usage depends on processor utilization, which can affect the game

How to set CPU performance to full in Win11

Feb 19, 2024 pm 07:42 PM

How to set CPU performance to full in Win11

Feb 19, 2024 pm 07:42 PM

Many users find that the computer is not running smoothly enough when using the Win11 system. They want to improve CPU performance, but they don't know how to do it. The following will introduce in detail how to set the CPU performance to the highest level in Win11 system to make your computer more efficient. Setting method: 1. Right-click "This PC" on the desktop and select "Properties" in the option list. 2. After entering the new interface, click "Advanced System Settings" in "Related Links". 3. In the window that opens, click the "Advanced" tab at the top, then click the & at the bottom of "Performance"

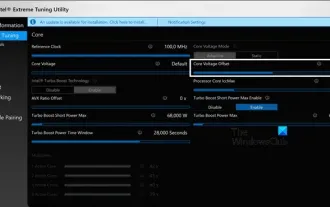

How to undervolt and overclock your CPU using Intel XTU

Feb 19, 2024 am 11:06 AM

How to undervolt and overclock your CPU using Intel XTU

Feb 19, 2024 am 11:06 AM

Intel XTU is a powerful application that allows you to easily manage your computer's performance. You can fix overheating issues by adjusting the CPU voltage, or boost performance by overclocking. In this article, we'll look at how you can take advantage of Intel XTU to optimize your computer's performance, whether that's adjusting voltage or overclocking. What effect do undervolting and overclocking have on the CPU? Before we move on to learning how to undervolt and overclock a CPU, we first have to understand what they are. Undervolting refers to gradually reducing the voltage required by the CPU. This process helps reduce heat emissions, as high voltage results in higher temperatures. By reducing the voltage supply to the CPU, the temperature can be effectively reduced. If your laptop starts to slow down after getting hot, you should solve the problem promptly.

The difference between boxed and bulk cpu

Jan 23, 2024 am 09:46 AM

The difference between boxed and bulk cpu

Jan 23, 2024 am 09:46 AM

The differences between boxed and bulk CPUs: 1. Quality; 2. Warranty period; 3. Fan; 4. Price; 5. Packaging; 6. Sales channels. Detailed introduction: 1. Quality, whether it is boxed or bulk, there is no difference in the quality of the CPU itself. They are all manufactured by the same manufacturer and undergo the same quality testing and quality control process; 2. Warranty period, boxed CPU A longer warranty period is usually provided, usually three years, while bulk CPUs usually only have a one-year warranty, this is because boxed CPUs are usually sold by official or authorized dealers, etc.

How to increase the clock frequency of your computer's CPU

Feb 20, 2024 am 09:54 AM

How to increase the clock frequency of your computer's CPU

Feb 20, 2024 am 09:54 AM

How to Overclock Computer CPUs With the continuous advancement of technology, people's demand for computer performance is also getting higher and higher. An effective way to improve computer performance is to increase the CPU's operating frequency through overclocking. Overclocking allows the CPU to process data faster, providing higher computing power. So, how to overclock a computer CPU? The following will introduce you to the basic principles and specific operation methods of overclocking. First, let's understand how overclocking works. The operating frequency of the CPU is determined by the crystal oscillator on the motherboard

The operation process of WIN10 service host occupying too much CPU

Mar 27, 2024 pm 02:41 PM

The operation process of WIN10 service host occupying too much CPU

Mar 27, 2024 pm 02:41 PM

1. First, we right-click the blank space of the taskbar and select the [Task Manager] option, or right-click the start logo, and then select the [Task Manager] option. 2. In the opened Task Manager interface, we click the [Services] tab on the far right. 3. In the opened [Service] tab, click the [Open Service] option below. 4. In the [Services] window that opens, right-click the [InternetConnectionSharing(ICS)] service, and then select the [Properties] option. 5. In the properties window that opens, change [Open with] to [Disabled], click [Apply] and then click [OK]. 6. Click the start logo, then click the shutdown button, select [Restart], and complete the computer restart.

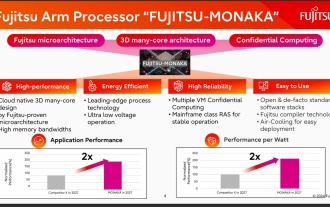

144-core, 3D-stacked SRAM: Fujitsu details next-generation data center processor MONAKA

Jul 29, 2024 am 11:40 AM

144-core, 3D-stacked SRAM: Fujitsu details next-generation data center processor MONAKA

Jul 29, 2024 am 11:40 AM

According to news from this website on July 28, foreign media TechRader reported that Fujitsu introduced in detail the FUJITSU-MONAKA (hereinafter referred to as MONAKA) processor planned to be shipped in 2027. MONAKACPU is based on the "cloud native 3D many-core" architecture and adopts the Arm instruction set. It is oriented to the data center, edge and telecommunications fields. It is suitable for AI computing and can realize mainframe-level RAS1. Fujitsu said that MONAKA will achieve a leap in energy efficiency and performance: thanks to technologies such as ultra-low voltage (ULV) technology, the CPU can achieve 2 times the energy efficiency of competing products in 2027, and cooling does not require water cooling; in addition, the application performance of the processor It can also reach twice as much as your opponent. In terms of instructions, MONAKA is equipped with vector

Leak reveals key specs of Intel Arrow Lake-U, -H, -HX and -S

Jun 15, 2024 pm 09:49 PM

Leak reveals key specs of Intel Arrow Lake-U, -H, -HX and -S

Jun 15, 2024 pm 09:49 PM

IntelArrowLakeisexpectedtobebasedonthesameprocessorarchitectureasLunarLake,meaningthatIntel'sbrandnewLionCoveperformancecoreswillbecombinedwiththeeconomicalSkymontefficiencycores.WhileLunarLakeisonlyavailableasava