Technology peripherals

Technology peripherals

AI

AI

Four steps for successful application of artificial intelligence in manufacturing

Four steps for successful application of artificial intelligence in manufacturing

Four steps for successful application of artificial intelligence in manufacturing

Manufacturers can benefit from artificial intelligence in a variety of ways, such as improving production, quality control and efficiency. While AI offers several new applications for manufacturers, to gain the most value, companies must use it throughout the entire manufacturing process.

This means manufacturing engineers need to focus on four key aspects of AI data preparation, modeling, simulation and testing, and deployment to successfully operate in uninterrupted manufacturing Artificial intelligence is used in the process.

No Need to Be an Artificial Intelligence Expert

Engineers may think that developing artificial intelligence models takes a considerable amount of time, but this is often not the case. Modeling is an important step in the workflow process, but it is not the end goal. The key to successfully using AI is to identify any issues at the beginning of the process. This lets engineers know which aspects of the workflow require investing time and resources to get the best results.

When discussing workflow, there are two points to consider:

Manufacturing systems are large and complex, and artificial intelligence is only one part of it. Therefore, AI needs to work together with all other working parts on the production line in all scenarios. Part of this is using industrial communication protocols, such as OPCUA, and other machine software, such as control and monitoring logic and human-machine interfaces, to collect data from sensors on the equipment.

In this case, engineers are already set up for success when incorporating AI because they already understand the device, regardless of whether they have extensive AI experience. In other words, if they are not an AI expert, they can still use their expertise to successfully add AI to their workflow.

AI-driven workflow

Building an AI-driven workflow requires 4 steps:

1. Data preparation

When there is no good When using data to train AI models, projects are more likely to fail. Therefore, data preparation is crucial. Wrong data can cost engineers time to figure out why the model doesn't work.

Training the model is usually the most time-consuming step, but it is also an important step. Engineers should start with the cleanest, labeled data possible and focus on feeding the data into the model rather than focusing on improving the model.

For example, engineers should focus on preprocessing and ensuring that the data fed into the model is correctly labeled, rather than adjusting parameters and fine-tuning the model. This ensures that the model understands and processes the data.

Another challenge is the difference between machine operators and machine manufacturers. The former usually has access to the device's operation, while the latter requires this data to train AI models. To ensure that machine manufacturers share data with machine operators (i.e. their customers), both parties should develop protocols and business models to govern this sharing.

Construction equipment manufacturer Caterpillar provides a great example of the importance of data preparation. It collects large amounts of field data, and while this is necessary for accurate AI modeling, it means a lot of time is needed for data cleaning and labeling. The company successfully leveraged MATLAB to streamline this process. It helps the company develop clean, labeled data that can then be fed into machine learning models, leveraging powerful insights from machinery in the field. Additionally, the process is scalable and flexible for users who have domain expertise but are not AI experts.

2. Artificial Intelligence Modeling

This phase begins after the data is cleaned and properly labeled. In effect, this is when the model learns from the data. Engineers know they have entered a successful modeling phase when they have an accurate and reliable model that can make intelligent decisions based on inputs. This stage also requires engineers to use machine learning, deep learning, or a combination of both to decide which result is most accurate.

In the modeling phase, whether using deep learning or machine learning models, it is important to have access to several algorithms of the artificial intelligence workflow, such as classification, prediction, and regression. As a starting point, the various pre-built models created by the wider community may be helpful. Engineers can also use flexible tools such as MATLAB and Simulink.

It’s worth noting that while algorithms and pre-built models are a good start, engineers should find the most efficient path to their specific implementation by using algorithms and examples from others in their field. Target. That's why MATLAB provides hundreds of different examples for building AI models across multiple domains.

Also, another aspect to consider is that tracking changes and logging training iterations is crucial. Tools like Experiment Manager can help achieve this by interpreting the parameters that lead to the most accurate models and reproducible results.

3. Simulation and testing

This step ensures that the AI model works correctly. AI models are part of a larger system and need to work with various parts of the system. For example, in manufacturing, AI models might support predictive maintenance, dynamic trajectory planning, or visual quality inspection.

The remaining machine software includes control, monitoring logic and other components. Simulation and testing let engineers know that parts of the model are working as expected, both on their own and with other systems. A model can only be used in the real world if it can be demonstrated that it works as expected and is effective enough to reduce risk.

No matter what the situation, the model must respond the way it should. Before using the model, engineers should understand several questions at this stage:

- Is the model highly accurate?

- In each scenario, does the model perform as expected?

- Are all edge cases covered?

Tools like Simulink allow engineers to check that the model behaves as expected before using it on a device. This helps avoid spending time and money on redesigns. These tools also help build a high level of trust by successfully simulating and testing the model's intended cases and confirming that expected goals are met.

4. Deployment

Once you are ready to deploy, the next step is to prepare the model in the language it will be used in. To do this, engineers often need to share an off-the-shelf model. This allows the model to be adapted to a specified control hardware environment, such as an embedded controller, PLC or edge device. Flexible tools like MATLAB can often generate final code in any type of scenario, providing engineers with the ability to deploy models in many different environments from different hardware vendors. They can do this without rewriting the original code.

For example, when deploying a model directly to a PLC, automatic code generation eliminates coding errors that may be included during manual programming. This also provides optimized C/C or IEC61131 code that will run efficiently on major vendors' PLCs.

Successful deployment of artificial intelligence does not require a data scientist or artificial intelligence expert. However, there are some key resources that can help engineers and their AI models prepare for success. This includes specific tools made for scientists and engineers, applications and capabilities to add AI to workflows, a variety of deployment options for use in non-stop operations, and experts ready to answer AI-related questions. Giving engineers the right resources to help successfully add AI will allow them to deliver the best results.

The above is the detailed content of Four steps for successful application of artificial intelligence in manufacturing. For more information, please follow other related articles on the PHP Chinese website!

Hot AI Tools

Undresser.AI Undress

AI-powered app for creating realistic nude photos

AI Clothes Remover

Online AI tool for removing clothes from photos.

Undress AI Tool

Undress images for free

Clothoff.io

AI clothes remover

AI Hentai Generator

Generate AI Hentai for free.

Hot Article

Hot Tools

Notepad++7.3.1

Easy-to-use and free code editor

SublimeText3 Chinese version

Chinese version, very easy to use

Zend Studio 13.0.1

Powerful PHP integrated development environment

Dreamweaver CS6

Visual web development tools

SublimeText3 Mac version

God-level code editing software (SublimeText3)

Hot Topics

1377

1377

52

52

Bytedance Cutting launches SVIP super membership: 499 yuan for continuous annual subscription, providing a variety of AI functions

Jun 28, 2024 am 03:51 AM

Bytedance Cutting launches SVIP super membership: 499 yuan for continuous annual subscription, providing a variety of AI functions

Jun 28, 2024 am 03:51 AM

This site reported on June 27 that Jianying is a video editing software developed by FaceMeng Technology, a subsidiary of ByteDance. It relies on the Douyin platform and basically produces short video content for users of the platform. It is compatible with iOS, Android, and Windows. , MacOS and other operating systems. Jianying officially announced the upgrade of its membership system and launched a new SVIP, which includes a variety of AI black technologies, such as intelligent translation, intelligent highlighting, intelligent packaging, digital human synthesis, etc. In terms of price, the monthly fee for clipping SVIP is 79 yuan, the annual fee is 599 yuan (note on this site: equivalent to 49.9 yuan per month), the continuous monthly subscription is 59 yuan per month, and the continuous annual subscription is 499 yuan per year (equivalent to 41.6 yuan per month) . In addition, the cut official also stated that in order to improve the user experience, those who have subscribed to the original VIP

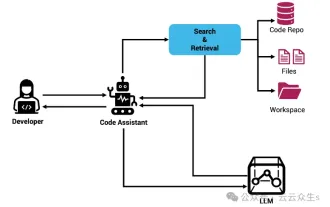

Context-augmented AI coding assistant using Rag and Sem-Rag

Jun 10, 2024 am 11:08 AM

Context-augmented AI coding assistant using Rag and Sem-Rag

Jun 10, 2024 am 11:08 AM

Improve developer productivity, efficiency, and accuracy by incorporating retrieval-enhanced generation and semantic memory into AI coding assistants. Translated from EnhancingAICodingAssistantswithContextUsingRAGandSEM-RAG, author JanakiramMSV. While basic AI programming assistants are naturally helpful, they often fail to provide the most relevant and correct code suggestions because they rely on a general understanding of the software language and the most common patterns of writing software. The code generated by these coding assistants is suitable for solving the problems they are responsible for solving, but often does not conform to the coding standards, conventions and styles of the individual teams. This often results in suggestions that need to be modified or refined in order for the code to be accepted into the application

Can fine-tuning really allow LLM to learn new things: introducing new knowledge may make the model produce more hallucinations

Jun 11, 2024 pm 03:57 PM

Can fine-tuning really allow LLM to learn new things: introducing new knowledge may make the model produce more hallucinations

Jun 11, 2024 pm 03:57 PM

Large Language Models (LLMs) are trained on huge text databases, where they acquire large amounts of real-world knowledge. This knowledge is embedded into their parameters and can then be used when needed. The knowledge of these models is "reified" at the end of training. At the end of pre-training, the model actually stops learning. Align or fine-tune the model to learn how to leverage this knowledge and respond more naturally to user questions. But sometimes model knowledge is not enough, and although the model can access external content through RAG, it is considered beneficial to adapt the model to new domains through fine-tuning. This fine-tuning is performed using input from human annotators or other LLM creations, where the model encounters additional real-world knowledge and integrates it

Seven Cool GenAI & LLM Technical Interview Questions

Jun 07, 2024 am 10:06 AM

Seven Cool GenAI & LLM Technical Interview Questions

Jun 07, 2024 am 10:06 AM

To learn more about AIGC, please visit: 51CTOAI.x Community https://www.51cto.com/aigc/Translator|Jingyan Reviewer|Chonglou is different from the traditional question bank that can be seen everywhere on the Internet. These questions It requires thinking outside the box. Large Language Models (LLMs) are increasingly important in the fields of data science, generative artificial intelligence (GenAI), and artificial intelligence. These complex algorithms enhance human skills and drive efficiency and innovation in many industries, becoming the key for companies to remain competitive. LLM has a wide range of applications. It can be used in fields such as natural language processing, text generation, speech recognition and recommendation systems. By learning from large amounts of data, LLM is able to generate text

To provide a new scientific and complex question answering benchmark and evaluation system for large models, UNSW, Argonne, University of Chicago and other institutions jointly launched the SciQAG framework

Jul 25, 2024 am 06:42 AM

To provide a new scientific and complex question answering benchmark and evaluation system for large models, UNSW, Argonne, University of Chicago and other institutions jointly launched the SciQAG framework

Jul 25, 2024 am 06:42 AM

Editor |ScienceAI Question Answering (QA) data set plays a vital role in promoting natural language processing (NLP) research. High-quality QA data sets can not only be used to fine-tune models, but also effectively evaluate the capabilities of large language models (LLM), especially the ability to understand and reason about scientific knowledge. Although there are currently many scientific QA data sets covering medicine, chemistry, biology and other fields, these data sets still have some shortcomings. First, the data form is relatively simple, most of which are multiple-choice questions. They are easy to evaluate, but limit the model's answer selection range and cannot fully test the model's ability to answer scientific questions. In contrast, open-ended Q&A

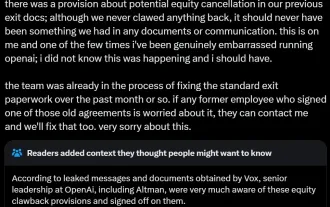

AI startups collectively switched jobs to OpenAI, and the security team regrouped after Ilya left!

Jun 08, 2024 pm 01:00 PM

AI startups collectively switched jobs to OpenAI, and the security team regrouped after Ilya left!

Jun 08, 2024 pm 01:00 PM

Last week, amid the internal wave of resignations and external criticism, OpenAI was plagued by internal and external troubles: - The infringement of the widow sister sparked global heated discussions - Employees signing "overlord clauses" were exposed one after another - Netizens listed Ultraman's "seven deadly sins" Rumors refuting: According to leaked information and documents obtained by Vox, OpenAI’s senior leadership, including Altman, was well aware of these equity recovery provisions and signed off on them. In addition, there is a serious and urgent issue facing OpenAI - AI safety. The recent departures of five security-related employees, including two of its most prominent employees, and the dissolution of the "Super Alignment" team have once again put OpenAI's security issues in the spotlight. Fortune magazine reported that OpenA

Five schools of machine learning you don't know about

Jun 05, 2024 pm 08:51 PM

Five schools of machine learning you don't know about

Jun 05, 2024 pm 08:51 PM

Machine learning is an important branch of artificial intelligence that gives computers the ability to learn from data and improve their capabilities without being explicitly programmed. Machine learning has a wide range of applications in various fields, from image recognition and natural language processing to recommendation systems and fraud detection, and it is changing the way we live. There are many different methods and theories in the field of machine learning, among which the five most influential methods are called the "Five Schools of Machine Learning". The five major schools are the symbolic school, the connectionist school, the evolutionary school, the Bayesian school and the analogy school. 1. Symbolism, also known as symbolism, emphasizes the use of symbols for logical reasoning and expression of knowledge. This school of thought believes that learning is a process of reverse deduction, through existing

SOTA performance, Xiamen multi-modal protein-ligand affinity prediction AI method, combines molecular surface information for the first time

Jul 17, 2024 pm 06:37 PM

SOTA performance, Xiamen multi-modal protein-ligand affinity prediction AI method, combines molecular surface information for the first time

Jul 17, 2024 pm 06:37 PM

Editor | KX In the field of drug research and development, accurately and effectively predicting the binding affinity of proteins and ligands is crucial for drug screening and optimization. However, current studies do not take into account the important role of molecular surface information in protein-ligand interactions. Based on this, researchers from Xiamen University proposed a novel multi-modal feature extraction (MFE) framework, which for the first time combines information on protein surface, 3D structure and sequence, and uses a cross-attention mechanism to compare different modalities. feature alignment. Experimental results demonstrate that this method achieves state-of-the-art performance in predicting protein-ligand binding affinities. Furthermore, ablation studies demonstrate the effectiveness and necessity of protein surface information and multimodal feature alignment within this framework. Related research begins with "S