Technology peripherals

Technology peripherals

AI

AI

An article talks about the related design scheme of intelligent driving system and software upgrade

An article talks about the related design scheme of intelligent driving system and software upgrade

An article talks about the related design scheme of intelligent driving system and software upgrade

Due to the trend of centralization of smart cars, the network connection has been upgraded from the traditional low-bandwidth Can network to the high-bandwidth Ethernet network. In order to improve the vehicle upgrade capability and provide car owners with continuous and high-quality experience and services, it is necessary to build on the existing system foundation (from the original upgrade of the traditional ECU on the vehicle to the process of incremental Ethernet upgrade) Develop a new OTA service system that is compatible with existing OTA systems to achieve OTA upgrade capabilities for vehicle software, firmware, and services, thereby ultimately improving user experience and service experience.

Software upgrade involves two major areas - FOTA/SOTA

The entire vehicle software upgrade is through OTA technology, which is a complete upgrade of in-vehicle entertainment and navigation. , human-computer interaction and other application software and steering, braking, body control and other firmware are upgraded. The vehicle OTA upgrade package is composed of upgrade packages that can upgrade the ECU in the upgrade object. For vehicle OTA types, they are mainly divided into two categories, FOTA (Firmware-over-the-air) and SOTA (Software-over-the-air). Both are areas that OEMs focus on and are gradually implementing. They can be adapted to OTA needs in different scenarios.

FOTA (also known as mobile terminal over-the-air software upgrade technology) achieves a complete upgrade and update of system functions by downloading and installing a complete firmware image to the vehicle controller. FOTA involves a complete systematic update of the core functions of the controller's related strategies, which has a greater impact on vehicle performance. The upgrade process has extremely high requirements on timing, stability, and safety. At the same time, the prerequisites for the upgrade include gear, power, and vehicle speed. and other requirements, the upgrade process generally does not support ignition vehicles.

FOTA achieves a complete upgrade and update of system functions by downloading and installing a complete firmware image for the vehicle controller. For example, upgrading the vehicle's smart driving system allows drivers to enjoy more and more auxiliary driving functions; upgrading the vehicle's cockpit system to improve the accuracy of driver fatigue detection; upgrading the vehicle's braking system to improve the vehicle's braking performance.

SOTA can actually be seen as the core requirement of a software sales strategy. It achieves an "increment" in the controller function by installing an "incremental package" on the vehicle controller. "Updated, generally used in entertainment systems and smart driving systems. For example, when changing the multimedia system operating interface, optimizing the dashboard display style, and updating the map program in the entertainment console, SOTA upgrade methods are used. SOTA involves a small-scale partial update of functions at the controller application layer, which has little impact on vehicle performance and requires low upgrade prerequisites. SOTA's incremental update strategy can significantly reduce the size of the upgrade package file, thereby saving network traffic and storage space.

Here we give examples of how FOTA and SOTA can be effectively defined in intelligent driving upgrades.

For example, upgrading the smart driving car system, in order to allow drivers to enjoy more and more assisted driving functions; the continuous update of phased functions is usually determined based on the difficulty and length of function development Iteration (including software changes from low-level functions to high-level functions). At the same time, the vehicle's cockpit system needs to be upgraded during the process to improve the accuracy of driver fatigue detection; the associated subsystems of intelligent driving vehicles (such as braking, steering system and other modules) need to be upgraded to improve the vehicle's braking performance.

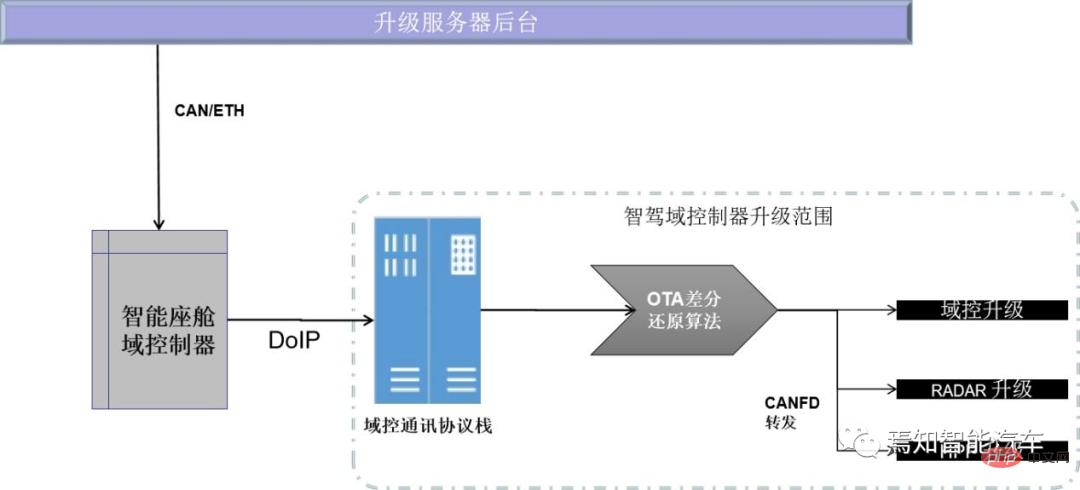

Software upgrade architecture in the intelligent driving system

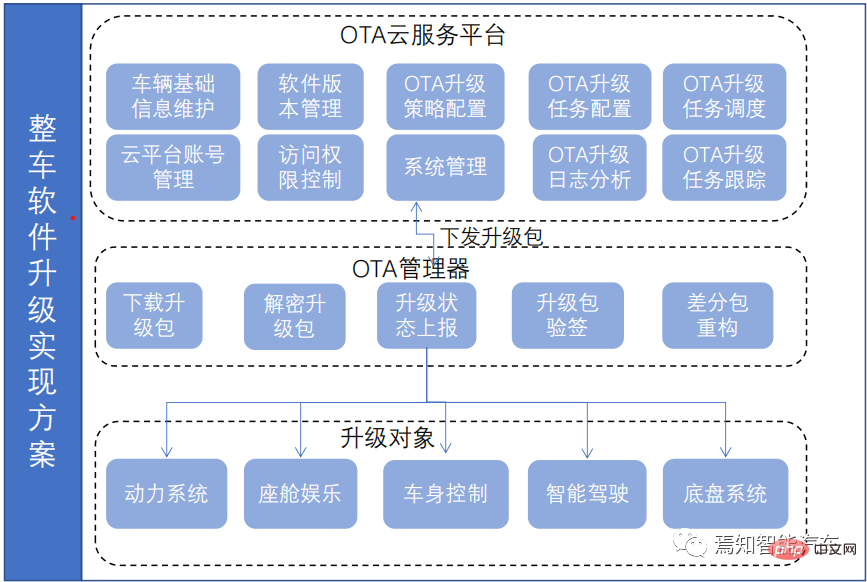

For the entire OTA upgrade, it mainly includes the following three aspects from bottom to top: Upgrade objects , OTA manager, OTA cloud service platform. The autonomous driving domain controller and the cockpit domain controller are connected through Ethernet, and the upgrade protocol is generally the commonly used DoIP. In addition to the domain controller itself, the upgrade process also includes high-precision positioning module upgrades and sensor upgrades. For cameras connected by Ethernet, the upgrade process is mainly through the entire integrated program installed on the main domain controller. In other words, for pure camera sensors, there is no separate program upgrade process. For the millimeter wave/ultrasonic radar equipped with CANFD, since it has its own controller, the upgrade process mainly involves connecting to the controller through CANFD. The domain control is connected to the public CAN through CANFD, and the cockpit domain is responsible for flashing the CANFD domain control. The transmitter forwards the message to each radar controller.

As shown in the figure above, the OTA cloud service platform mainly manages and delivers OTA upgrade packages, and completes the configuration, scheduling and tracking of upgrade tasks. The OTA manager mainly completes the downloading, decryption, signature verification, differential package reconstruction and other functions of the upgrade package, and finally sends the upgrade package to the corresponding upgrade object. The upgrade object is composed of one or more ECUs. After the upgrade object receives the upgrade package, it sends the corresponding ECU upgrade package to the corresponding ECU, and the ECU completes the flashing of the upgrade package.

Principle of the upgrade process in the smart driving system

The current upgrade method is mainly silent upgrade. That is, it includes sensible upgrades in normal mode and unconscious upgrades in abnormal mode. The normal mode is actually in the factory mode. After the multimedia receives the upgrade command, it downloads the upgrade package when the upgrade conditions are met, and performs automated vehicle upgrades. During the upgrade process, if after receiving the signal of unlocking/opening the door/pressing the start button/unlocking the cloud service, the vehicle display will not display the OTA upgrade, and the vehicle will be in a silent state during the regular upgrade process.

Perform silent upgrade in non-factory mode, and upgrade without the user being aware of it as a reserved solution. Due to restrictions by relevant national laws, the implementation of this solution requires all modules of intelligent driving to meet the two-sided partition upgrade strategy. The two-sided distinction here refers to the A/B double-sided upgrade process. That is to say, two storage spaces A/B are opened for the SOC in the domain controller. Each storage space is installed with a system. When one system is in active use, the other system will be in standby state. When upgrading the system, you can upgrade the standby system in the activated system. After the upgrade is completed, restart and switch to the newly upgraded system. Therefore, the upgrade process in the SOC of smart driving domain control can be described as when the operating area is area A, then upgrade area B. After the upgrade is completed, restart from area B. After startup, synchronize area B to area A at the right time. . And when the SOC upgrade fails, enabled driving is not allowed.

In addition, for MCU flashing in domain control, it is best to use the dual APP mechanism. That is, the MCU adopts a bootloader single-zone and app dual-zone deployment method, and the bootloader generally does not need to be upgraded. Therefore, the MCU upgrade process only needs to be performed on APPs deployed in dual zones.

During the entire upgrade process, you need to complete the following upgrade tasks:

1) Upgrade precondition judgment:

Obtain the vehicle’s current status check through in-vehicle networks such as Ethernet and CAN, and customize it according to the actual needs of the project, including but not limited to battery power, Engine speed, vehicle speed, vehicle gear, handbrake status, seat sensor status, door status, lock status, etc. Before the upgrade starts, the cockpit domain controller needs to perform a status check on the upgraded vehicle and then continue with subsequent actions. Check items for its current status include: remaining internal storage space of the module, module hardware version, module firmware version, and module software version. Normally, during the upgrade process, it is necessary to determine whether the vehicle is stationary, whether the gear is in P gear, and whether the SOC power of the domain controller is greater than a certain threshold. Under appropriate circumstances, the scheduled upgrade or immediate upgrade instructions will pop up on the central control interface/electrical inspection computer display. There are two situations that will trigger the upgrade: power-on and power-off self-test and user-initiated triggering. The upgrade condition is triggered. If the trigger is successful, proceed to the next step. Otherwise, exit the upgrade process.

2) Download the upgrade package:

In the process of delivering the cloud upgrade strategy and upgrade package, the cloud needs To detect whether the version number has been updated, the OTA upgrade server delivers the upgrade policy package to the cockpit domain controller. Users will not be aware of this process. The cockpit domain controller supports conventional flash upgrade methods, DoIP and CAN flash.

Software flashing based on CAN protocol

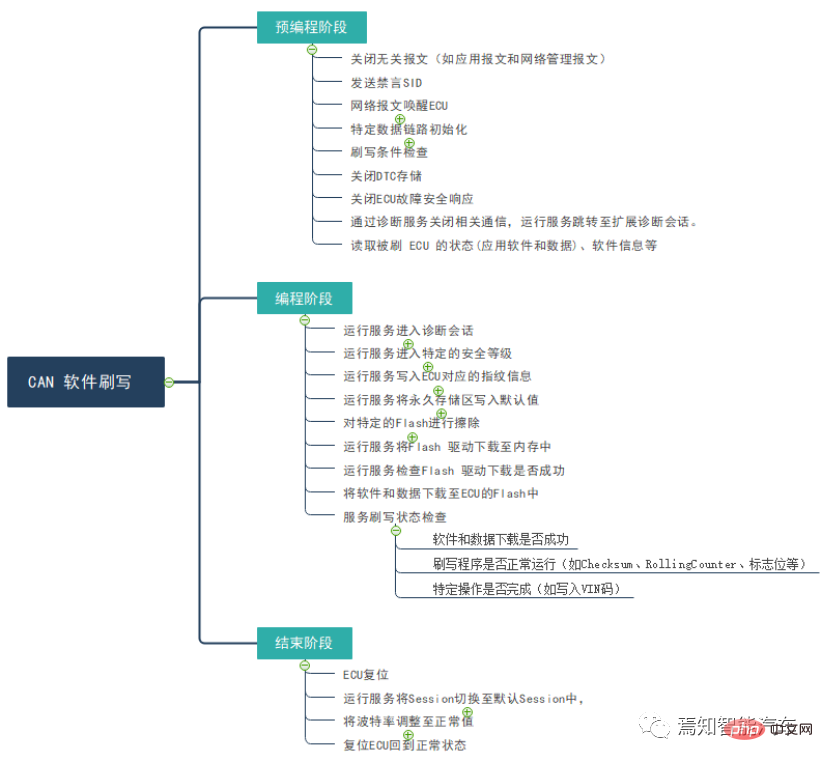

The CAN flashing process is actually a process based on specifications (the specifications mainly Is the process of programming according to ISO 14229). During the programming process, you need to specify and refer to the following types of different steps for effective addressing and service access:

Standard steps are mandatory steps that require clients and servers to act in accordance with the regulations under any circumstances. Recommended steps are optional, require the use of a specific diagnostic service identifier, and contain recommendations on how to perform actions. This alternative only requires that the client and server behave as specified when using the specified functionality. OEM implementation step: Its use and content (e.g. diagnostic service identifiers used) are at the discretion of the vehicle manufacturer and may of course be an optional step.

CAN software flashing is mainly divided into three stages: pre-programming stage, programming stage, and end stage. The corresponding business processes required at each stage are shown in the figure below:

##Detailed explanation of software flashing based on DoIP protocol

DoIP (Diagnostic communication over Internet Protocol), as a diagnostic based on vehicle Ethernet, mainly exists in the transport layer of the OSI seven-layer model. DoIP transmits UDS diagnostic data on the Ethernet network transmission protocol. DoIP has high bandwidth and is suitable for scenarios where large amounts of data are transmitted, making it very suitable for OTA software upgrades in vehicles. Compared with CAN, DoIP mainly optimizes data transmission and improves the speed at the physical layer and transport layer. In the application layer and diagnostic service links, the implementation of CAN and DoIP is based on the 14229 protocol. In the ODX database part, except for adding DoIP protocol communication parameters and related controllers, generally no additional adjustments are required, which greatly saves diagnostic data development time and cost.

DoIP file flashing mainly includes DoIP flashing without a file system controller and DoIP flashing with a file system controller. For flashing the file system controller, the overall scheme is similar to the CAN node flashing scheme. The multimedia host transmits by address, and the controller writes by address. For controllers with a file system, the multimedia host only needs to transmit the upgrade package to the controller (of course, it needs to be able to support breakpoint resumption during the process), and there are no other requirements.

Currently, the commonly used DoIP diagnostic connection methods are divided into two types: one is the Ethernet cable direct connection form: in the case of the entire vehicle, make an OBD-Ethernet cable direct connection Second, it is compatible with CAN/CAN FD communication and meets production and after-sales needs. It realizes DoIP communication by using the diagnostic VCI to integrate the Ethernet activation function. After the database is created, the vehicle flashing process can be realized using relevant diagnostic tools.

After the cockpit domain control receives the vehicle factory mode automated upgrade command issued by the server, it requests the server to automatically download the upgrade package and automatically upgrades the vehicle if the upgrade conditions are met. , supports functions such as breakpoint resumption, integrity verification, storage space management, etc.

3) Smart driving domain controller upgrade status feedback:

The smart driving domain controller reports to the domain controller The information is sent to the cockpit domain controller to complete the precondition judgment for the upgrade. Only when the conditions are met can the OTA upgrade be entered. Upgrading this type of information needs to be uploaded to the OTA server. This type of information includes the software/hardware version number, serial number (SN), positioning information (GPS), etc. of each module of the domain controller.

4) Perform the upgrade task:

The cockpit domain controller will upgrade based on the upgrade package issued by the server. Policy and other information, perform OTA upgrade. If joint upgrade and flashing of multiple ECUs is required at the same time, it is necessary to send point-to-point upgrade interaction information to the corresponding controller according to the issued upgrade task sequence in order to complete the corresponding upgrade task.

5) Breakpoint continuation upgrade:

Breakpoint continuation upgrade refers to state machine-based management. During the upgrade process, the currently upgraded files or block devices are backed up and stored. If an interruption, power outage, or other interference occurs during the upgrade process, causing the file being upgraded to be damaged, then the controller will record the current upgrade status, and the controller will execute a certain verification algorithm the next time the program is restarted ( (such as hash verification) to evaluate whether the file has been damaged. If the program is intact, it will be upgraded directly in the order of programs that have not been marked for upgrade. If the file is corrupted, the backup storage is used to restore the upgrade.

The entire upgrade process generally requires several retry opportunities after flash failure. If there are dependencies on associated modules, all upgraded associated modules need to be rolled back.

6) Linked upgrade management:

For ECUs with related functions (such as front millimeter wave radar upgrade can Treated as a linked upgrade of the same nature), the background can set the linked upgrade, and can also set the upgrade sequence for the associated ECU. The upgrade process is that when the cockpit domain controller obtains the upgrade task from the background, it will detect whether there is a linkage upgrade requirement in the upgrade command. If so, it will upgrade one by one in order and associate it with the ECU.

The cockpit domain controller will manage and continuously distribute upgrade packages during the entire upgrade process, monitor the entire upgrade process until all ECUs have completed the upgrade, and then uniformly report the background upgrade results. When it is detected that any ECU upgrade fails and needs to be rolled back, the controller will link all associated ECUs to synchronize the version rollback. At the same time, the cockpit domain controller will effectively report which ECU upgrade failed resulting in rollback.

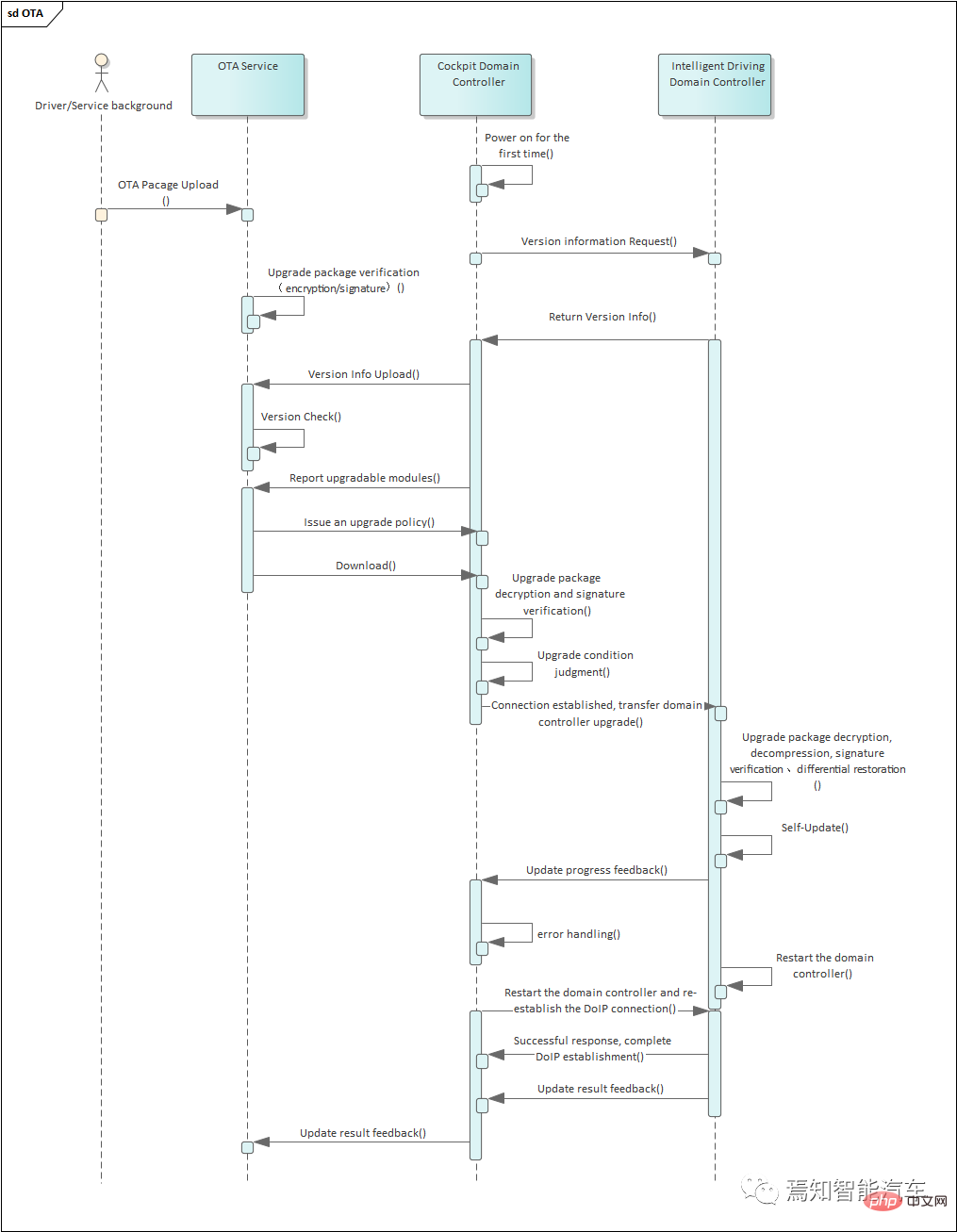

The corresponding software upgrade sequence diagram is as follows:

Based on the above description, each module of the vehicle is upgraded It can be summarized as follows: the OTA server issues an upgrade policy file to determine the upgrade sequence. The policy file is generated when the upgrade is configured on the server. The cockpit domain control formulates the upgrade plan and sequence of each ECU based on the policy file. The upgrade order of intelligent driving related modules is controlled according to the following priority order: CAN module -> DoIP module without file system -> DoIP with file system.

Compared with CAN, DoIP mainly optimizes data transmission and improves the speed at the physical layer and transport layer. In the application layer and diagnostic service links, the implementation of CAN and DoIP is based on the 14229 protocol.

For intelligent driving systems, software upgrades have become an indispensable part. While providing customers with real-time online upgrade functions, domain controllers need to meet cloud secure communications, including protocol communication link management, upgrade instruction reception and upgrade status transmission, upgrade package download, upgrade package decryption, differential package reconstruction, and upgrade package verification. For legality verification, it also includes key certificate management services, data encryption services, digital signature services and other functions. It can be said that intelligent driving-level software upgrades are the driving force behind its continuous development.

The above is the detailed content of An article talks about the related design scheme of intelligent driving system and software upgrade. For more information, please follow other related articles on the PHP Chinese website!

Hot AI Tools

Undresser.AI Undress

AI-powered app for creating realistic nude photos

AI Clothes Remover

Online AI tool for removing clothes from photos.

Undress AI Tool

Undress images for free

Clothoff.io

AI clothes remover

AI Hentai Generator

Generate AI Hentai for free.

Hot Article

Hot Tools

Notepad++7.3.1

Easy-to-use and free code editor

SublimeText3 Chinese version

Chinese version, very easy to use

Zend Studio 13.0.1

Powerful PHP integrated development environment

Dreamweaver CS6

Visual web development tools

SublimeText3 Mac version

God-level code editing software (SublimeText3)

Hot Topics

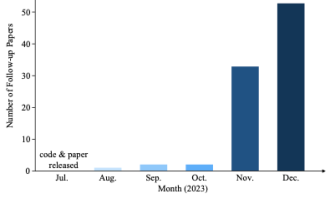

1378

1378

52

52

Why is Gaussian Splatting so popular in autonomous driving that NeRF is starting to be abandoned?

Jan 17, 2024 pm 02:57 PM

Why is Gaussian Splatting so popular in autonomous driving that NeRF is starting to be abandoned?

Jan 17, 2024 pm 02:57 PM

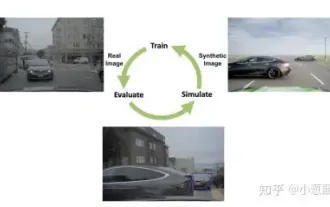

Written above & the author’s personal understanding Three-dimensional Gaussiansplatting (3DGS) is a transformative technology that has emerged in the fields of explicit radiation fields and computer graphics in recent years. This innovative method is characterized by the use of millions of 3D Gaussians, which is very different from the neural radiation field (NeRF) method, which mainly uses an implicit coordinate-based model to map spatial coordinates to pixel values. With its explicit scene representation and differentiable rendering algorithms, 3DGS not only guarantees real-time rendering capabilities, but also introduces an unprecedented level of control and scene editing. This positions 3DGS as a potential game-changer for next-generation 3D reconstruction and representation. To this end, we provide a systematic overview of the latest developments and concerns in the field of 3DGS for the first time.

How to solve the long tail problem in autonomous driving scenarios?

Jun 02, 2024 pm 02:44 PM

How to solve the long tail problem in autonomous driving scenarios?

Jun 02, 2024 pm 02:44 PM

Yesterday during the interview, I was asked whether I had done any long-tail related questions, so I thought I would give a brief summary. The long-tail problem of autonomous driving refers to edge cases in autonomous vehicles, that is, possible scenarios with a low probability of occurrence. The perceived long-tail problem is one of the main reasons currently limiting the operational design domain of single-vehicle intelligent autonomous vehicles. The underlying architecture and most technical issues of autonomous driving have been solved, and the remaining 5% of long-tail problems have gradually become the key to restricting the development of autonomous driving. These problems include a variety of fragmented scenarios, extreme situations, and unpredictable human behavior. The "long tail" of edge scenarios in autonomous driving refers to edge cases in autonomous vehicles (AVs). Edge cases are possible scenarios with a low probability of occurrence. these rare events

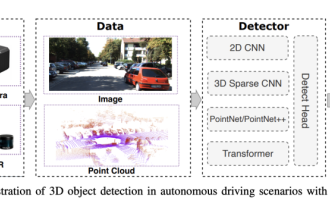

Choose camera or lidar? A recent review on achieving robust 3D object detection

Jan 26, 2024 am 11:18 AM

Choose camera or lidar? A recent review on achieving robust 3D object detection

Jan 26, 2024 am 11:18 AM

0.Written in front&& Personal understanding that autonomous driving systems rely on advanced perception, decision-making and control technologies, by using various sensors (such as cameras, lidar, radar, etc.) to perceive the surrounding environment, and using algorithms and models for real-time analysis and decision-making. This enables vehicles to recognize road signs, detect and track other vehicles, predict pedestrian behavior, etc., thereby safely operating and adapting to complex traffic environments. This technology is currently attracting widespread attention and is considered an important development area in the future of transportation. one. But what makes autonomous driving difficult is figuring out how to make the car understand what's going on around it. This requires that the three-dimensional object detection algorithm in the autonomous driving system can accurately perceive and describe objects in the surrounding environment, including their locations,

The Stable Diffusion 3 paper is finally released, and the architectural details are revealed. Will it help to reproduce Sora?

Mar 06, 2024 pm 05:34 PM

The Stable Diffusion 3 paper is finally released, and the architectural details are revealed. Will it help to reproduce Sora?

Mar 06, 2024 pm 05:34 PM

StableDiffusion3’s paper is finally here! This model was released two weeks ago and uses the same DiT (DiffusionTransformer) architecture as Sora. It caused quite a stir once it was released. Compared with the previous version, the quality of the images generated by StableDiffusion3 has been significantly improved. It now supports multi-theme prompts, and the text writing effect has also been improved, and garbled characters no longer appear. StabilityAI pointed out that StableDiffusion3 is a series of models with parameter sizes ranging from 800M to 8B. This parameter range means that the model can be run directly on many portable devices, significantly reducing the use of AI

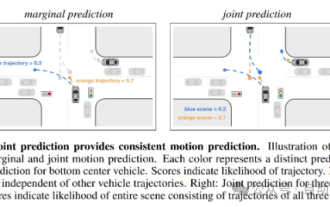

This article is enough for you to read about autonomous driving and trajectory prediction!

Feb 28, 2024 pm 07:20 PM

This article is enough for you to read about autonomous driving and trajectory prediction!

Feb 28, 2024 pm 07:20 PM

Trajectory prediction plays an important role in autonomous driving. Autonomous driving trajectory prediction refers to predicting the future driving trajectory of the vehicle by analyzing various data during the vehicle's driving process. As the core module of autonomous driving, the quality of trajectory prediction is crucial to downstream planning control. The trajectory prediction task has a rich technology stack and requires familiarity with autonomous driving dynamic/static perception, high-precision maps, lane lines, neural network architecture (CNN&GNN&Transformer) skills, etc. It is very difficult to get started! Many fans hope to get started with trajectory prediction as soon as possible and avoid pitfalls. Today I will take stock of some common problems and introductory learning methods for trajectory prediction! Introductory related knowledge 1. Are the preview papers in order? A: Look at the survey first, p

SIMPL: A simple and efficient multi-agent motion prediction benchmark for autonomous driving

Feb 20, 2024 am 11:48 AM

SIMPL: A simple and efficient multi-agent motion prediction benchmark for autonomous driving

Feb 20, 2024 am 11:48 AM

Original title: SIMPL: ASimpleandEfficientMulti-agentMotionPredictionBaselineforAutonomousDriving Paper link: https://arxiv.org/pdf/2402.02519.pdf Code link: https://github.com/HKUST-Aerial-Robotics/SIMPL Author unit: Hong Kong University of Science and Technology DJI Paper idea: This paper proposes a simple and efficient motion prediction baseline (SIMPL) for autonomous vehicles. Compared with traditional agent-cent

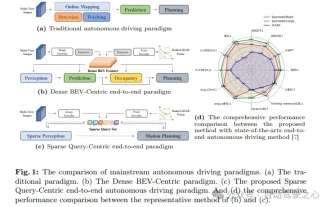

nuScenes' latest SOTA | SparseAD: Sparse query helps efficient end-to-end autonomous driving!

Apr 17, 2024 pm 06:22 PM

nuScenes' latest SOTA | SparseAD: Sparse query helps efficient end-to-end autonomous driving!

Apr 17, 2024 pm 06:22 PM

Written in front & starting point The end-to-end paradigm uses a unified framework to achieve multi-tasking in autonomous driving systems. Despite the simplicity and clarity of this paradigm, the performance of end-to-end autonomous driving methods on subtasks still lags far behind single-task methods. At the same time, the dense bird's-eye view (BEV) features widely used in previous end-to-end methods make it difficult to scale to more modalities or tasks. A sparse search-centric end-to-end autonomous driving paradigm (SparseAD) is proposed here, in which sparse search fully represents the entire driving scenario, including space, time, and tasks, without any dense BEV representation. Specifically, a unified sparse architecture is designed for task awareness including detection, tracking, and online mapping. In addition, heavy

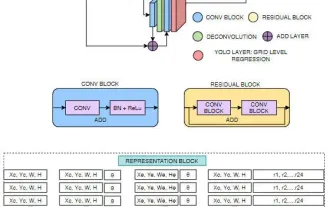

FisheyeDetNet: the first target detection algorithm based on fisheye camera

Apr 26, 2024 am 11:37 AM

FisheyeDetNet: the first target detection algorithm based on fisheye camera

Apr 26, 2024 am 11:37 AM

Target detection is a relatively mature problem in autonomous driving systems, among which pedestrian detection is one of the earliest algorithms to be deployed. Very comprehensive research has been carried out in most papers. However, distance perception using fisheye cameras for surround view is relatively less studied. Due to large radial distortion, standard bounding box representation is difficult to implement in fisheye cameras. To alleviate the above description, we explore extended bounding box, ellipse, and general polygon designs into polar/angular representations and define an instance segmentation mIOU metric to analyze these representations. The proposed model fisheyeDetNet with polygonal shape outperforms other models and simultaneously achieves 49.5% mAP on the Valeo fisheye camera dataset for autonomous driving