Making chips on plastic for less than 1 cent each

Imagine that the objects around you are full of intelligence. A bandage, a banana peel, a bottle, etc. are all intelligent. At present, this kind of scene can only appear in science fiction movies. You may be wondering why all this has not been realized with the rapid development of technology today. This is because humans have not yet produced cheap processors.

The number of IoT devices worldwide is growing by billions every year. It may seem like a huge number, but in reality the potential in this area is much greater, and fairly expensive silicon chips are holding it back. The solution might be to introduce plastic chips that are many times cheaper.

Some research institutions have made various attempts before. For example, in 2021, Arm launched the PlasticArm M0 new plastic chip prototype, which can print circuits directly on paper, plastic or fabric. This chip does not use silicon as a substrate. Instead, it uses a plastic processor core, which is a project that Arm has been researching for nearly ten years, but even so Arm's research cannot meet the standards.

The problem, say engineers at the University of Illinois at Urbana-Champaign and British chipmaker PragmatIC Semiconductor, is that even the simplest industry-standard microcontrollers are too complex to be mass-produced on plastic.

At the International Symposium on Computer Architecture later this month, a research team from the University of Illinois at Urbana-Champaign will demonstrate a simple but functional plastic Processors that can be manufactured for less than a penny. The team designed both 4-bit and 8-bit processors. However, further details of this study have not been made public.

Team leader Rakesh Kumar said, "About 81% of the 4-bit processors can work, which is enough to break the 1-cent threshold."

Rakesh Kumar

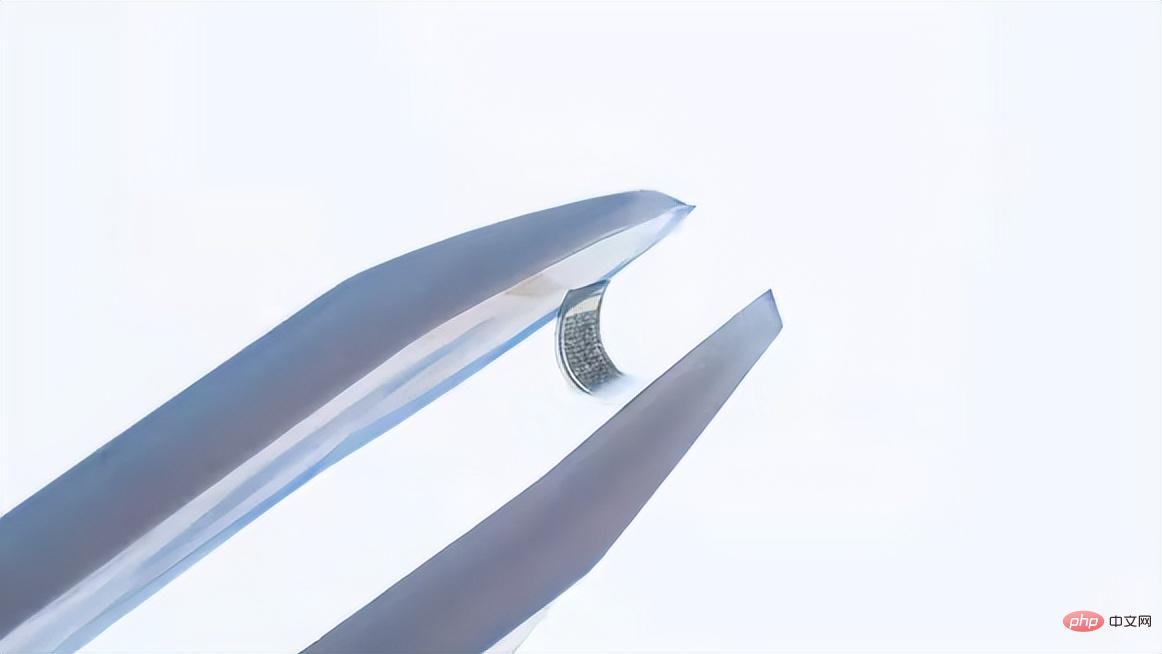

Kumar said that flexible electronics have been a segment of the market for decades, and the processor made by the team is made using the flexible thin-film semiconductor indium gallium zinc oxide (IGZO), which Thin film semiconductors can be built on plastic and continue to work even when bent within a radius of a few millimeters. But while a solid manufacturing process is a prerequisite, it’s the design that makes the difference.

Source: https://technewsspace.com/scientists-have-developed-penny-plastic-flexicore-chips-they-promise-to-revolutionize -the-internet-of-things/

Why not silicon?

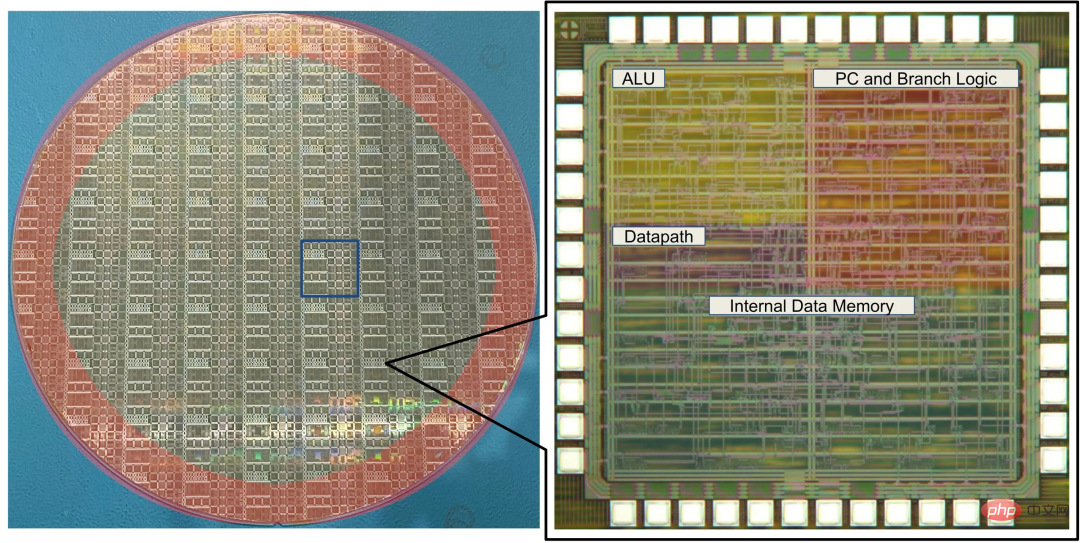

You may be wondering, why can’t silicon processors be made super cheap and have flexible computing performance? Kumar’s analysis concluded that this was impossible. Silicon is expensive and inflexible compared to plastic, and if you make a plastic chip small enough, it can continue to work within the range of bends. There are two reasons why silicon fails: One is that although the area of the circuit can be made very small, you still need to leave a relatively large space at the edge of the chip to cut the chip out of the wafer. For a typical microcontroller, there is more space at the edge of the chip than the area containing the circuitry. What's more, you also need more space to install enough I/O pads so that data and power can enter the chip. As a result, blank silicon wafers will be wasted.

Rather than adapt an existing microcontroller architecture to plastic, Kumar's team created a design called Flexicore from scratch. Since the scrap rate increases with the number of logic elements. Knowing this, they came up with an alternative design aimed at minimizing the number of doors required. They use 4-bit and 8-bit logic instead of 16-bit or 32-bit logic. Like separating the memory where instructions are stored from the memory where data is stored. But this comes with reducing the number and complexity of instructions the processor can execute.

The team further simplified the design of the processor, designing it to execute instructions in a single clock cycle rather than the multistep pipeline of today's CPUs. They then implemented the logic for these instructions by reusing parts, which further reduced the gate count. "Overall, we were able to simplify the design of FlexiCores by tailoring them to the needs of flexible applications, which tend to be computationally simple," said Kumar's student Nathaniel Bleier.

Through the above design, the team achieved a 4-bit FlexiCore chip with 5.6 mm^2, consisting of only 2104 semiconductor devices (about the same number of transistors in the classic Intel 4004 in 1971), and last year PlasticARM, the soft microprocessor developed by the Arm team, consists of approximately 56,340 devices. “In terms of gate count, FlexiCore is an order of magnitude less than the smallest silicon microcontrollers,” said Nathaniel Bleier.

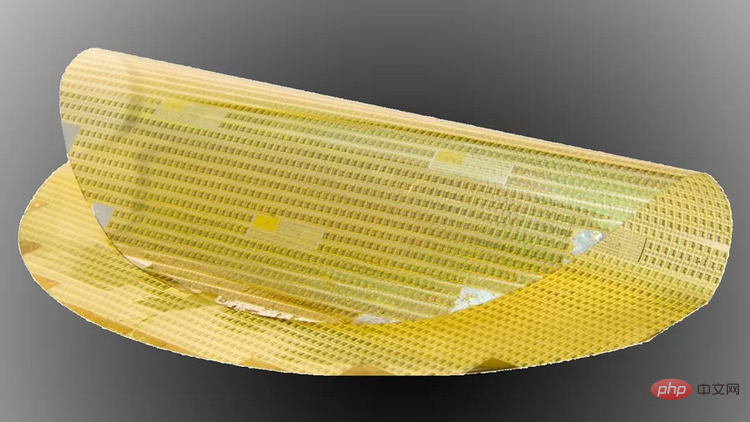

Engineers used PragmatIC’s manufacturing process to fabricate 4-bit microcontrollers on plastic.

FlexiCore also features optimized onboard memory and instruction sets to minimize transistor count and reduce complexity. The researchers also designed the logic components so that they could use a minimum number of transistors. After all, processors are designed to execute one instruction in one clock cycle.

In addition, the team also developed an 8-bit version of FlexiCore, but the effect was not good.

“This is exactly the kind of design innovation needed to support truly ubiquitous electronics,” said Scott White, CEO of PragmatIC Semiconductor.

Using PragmatIC technology, the team produced plastic-coated wafers with 4-bit and 8-bit processors, tested them in multiple programs at different voltages, and bent them mercilessly . The experiment may seem basic, but according to Kumar, it is groundbreaking. Most processors built using non-silicon technologies have such poor yield that results can only be reported from one or at most a few working chips. "As far as we know, this is the first time that data from non-silicon technologies can be reported across multiple chips," Kumar said.

PragmatIC has been working on low-cost chips

Kumar observed that the chip industry aims to balance power and performance metrics, along with some degree of reliability . They are not focusing on cost, consistency and chip thinness. Instead, the focus is on building new computer architectures and targeting new applications.

John A. Rogers, a pioneer in flexible electronics at Northwestern University, called the work impressive and looked forward to future developments in this research.

Of course, this is only what this study has done so far, and there is much more work to be done before the FlexiCore solution or similar solutions are commercially available. However, researchers have tried to optimize their solutions for different processes and target workloads, with some success. There are also questions about how bending affects performance and the durability of plastic chips.

However, with such cheap plastic processors and flexible electronics becoming mainstream, we may soon see the dawn of truly ubiquitous electronics. This kind of chip can be placed on the packaging of almost any product or on a medical patch, and its application fields are no longer limited.

The above is the detailed content of Making chips on plastic for less than 1 cent each. For more information, please follow other related articles on the PHP Chinese website!

Hot AI Tools

Undresser.AI Undress

AI-powered app for creating realistic nude photos

AI Clothes Remover

Online AI tool for removing clothes from photos.

Undress AI Tool

Undress images for free

Clothoff.io

AI clothes remover

AI Hentai Generator

Generate AI Hentai for free.

Hot Article

Hot Tools

Notepad++7.3.1

Easy-to-use and free code editor

SublimeText3 Chinese version

Chinese version, very easy to use

Zend Studio 13.0.1

Powerful PHP integrated development environment

Dreamweaver CS6

Visual web development tools

SublimeText3 Mac version

God-level code editing software (SublimeText3)

Hot Topics

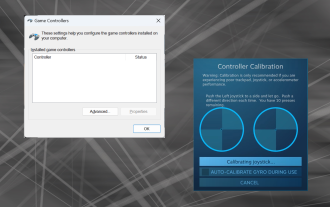

How to properly calibrate your Xbox One controller on Windows 11

Sep 21, 2023 pm 09:09 PM

How to properly calibrate your Xbox One controller on Windows 11

Sep 21, 2023 pm 09:09 PM

Since Windows has become the gaming platform of choice, it's even more important to identify its gaming-oriented features. One of them is the ability to calibrate an Xbox One controller on Windows 11. With built-in manual calibration, you can get rid of drift, random movement, or performance issues and effectively align the X, Y, and Z axes. If the available options don't work, you can always use a third-party Xbox One controller calibration tool. Let’s find out! How do I calibrate my Xbox controller on Windows 11? Before proceeding, make sure you connect your controller to your computer and update your Xbox One controller's drivers. While you're at it, also install any available firmware updates. 1. Use Wind

NVIDIA is not the only beneficiary, AI training also benefits memory chip manufacturers

May 31, 2023 pm 05:16 PM

NVIDIA is not the only beneficiary, AI training also benefits memory chip manufacturers

May 31, 2023 pm 05:16 PM

According to news on May 30, although the memory chip market is sluggish, there is a huge demand for artificial intelligence, which will benefit companies such as Samsung and SK Hynix. On May 24, Nvidia released its financial report, and the company’s market value surged by US$207 billion in two days. Previously, the semiconductor industry had been in a downturn, and this financial report forecast gave people great confidence and hope. If the field of artificial intelligence takes off, traditional technology giants like Microsoft and start-ups such as OpenAI will seek help from companies such as Samsung and SK Hynix. Machine learning requires memory chips to process large amounts of data, analyze video, audio and text, and simulate human creativity. In fact, AI companies may be buying more DRAM chips than ever before. Memory chip demand

Is the 1nm chip made in China or the United States?

Nov 06, 2023 pm 01:30 PM

Is the 1nm chip made in China or the United States?

Nov 06, 2023 pm 01:30 PM

It is not certain who made the 1nm chip. From a research and development perspective, the 1nm chip was jointly developed by Taiwan, China and the United States. From a mass production perspective, this technology is not yet fully realized. The main person in charge of this research is Dr. Zhu Jiadi of MIT, who is a Chinese scientist. Dr. Zhu Jiadi said that the research is still in its early stages and is still a long way from mass production.

First in China: Changxin Memory launches LPDDR5 DRAM memory chip

Nov 28, 2023 pm 09:29 PM

First in China: Changxin Memory launches LPDDR5 DRAM memory chip

Nov 28, 2023 pm 09:29 PM

News from this site on November 28. According to the official website of Changxin Memory, Changxin Memory has launched the latest LPDDR5DRAM memory chip. It is the first domestic brand to launch independently developed and produced LPDDR5 products, achieving a breakthrough in the domestic market and also making Changxin Storage's product layout in the mobile terminal market is more diversified. This website noticed that Changxin Memory LPDDR5 series products include 12Gb LPDDR5 particles, POP packaged 12GBLPDDR5 chips and DSC packaged 6GBLPDDR5 chips. The 12GBLPDDR5 chip has been verified on models of mainstream domestic mobile phone manufacturers such as Xiaomi and Transsion. LPDDR5 is a product launched by Changxin Storage for the mid-to-high-end mobile device market.

It is reported that TSMC's advanced packaging customers are chasing orders significantly, and monthly production capacity is planned to increase by 120% next year

Nov 13, 2023 pm 12:29 PM

It is reported that TSMC's advanced packaging customers are chasing orders significantly, and monthly production capacity is planned to increase by 120% next year

Nov 13, 2023 pm 12:29 PM

News from this site on November 13, according to Taiwan Economic Daily, TSMC’s CoWoS advanced packaging demand is about to explode. In addition to NVIDIA, which has confirmed expanded orders in October, heavyweight customers such as Apple, AMD, Broadcom, and Marvell have also recently pursued orders significantly. According to reports, TSMC is working hard to accelerate the expansion of CoWoS advanced packaging production capacity to meet the needs of the above-mentioned five major customers. Next year's monthly production capacity is expected to increase by about 20% from the original target to 35,000 pieces. Analysts said that TSMC's five major customers have placed large orders, which shows that artificial intelligence applications have become widely popular, and major manufacturers are interested in artificial intelligence chips. The demand has increased significantly. Inquiries on this site found that the current CoWoS advanced packaging technology is mainly divided into three types - CoWos-S

Learning Laravel from scratch: Detailed explanation of controller method invocation

Mar 10, 2024 pm 05:03 PM

Learning Laravel from scratch: Detailed explanation of controller method invocation

Mar 10, 2024 pm 05:03 PM

Learning Laravel from scratch: Detailed explanation of controller method invocation In the development of Laravel, controller is a very important concept. The controller serves as a bridge between the model and the view, responsible for processing requests from routes and returning corresponding data to the view for display. Methods in controllers can be called by routes. This article will introduce in detail how to write and call methods in controllers, and will provide specific code examples. First, we need to create a controller. You can use the Artisan command line tool to create

Is Nvidia's era of dominance over? ChatGPT sets off a chip war between Google and Microsoft, and Amazon also joins the game

May 22, 2023 pm 10:55 PM

Is Nvidia's era of dominance over? ChatGPT sets off a chip war between Google and Microsoft, and Amazon also joins the game

May 22, 2023 pm 10:55 PM

After ChatGPT became popular, the AI war between the two giants Google and Microsoft has burned into a new field-server chips. Today, AI and cloud computing have become battlegrounds, and chips have also become the key to reducing costs and winning business customers. Originally, major companies such as Amazon, Microsoft, and Google were all famous for their software, but now they are spending billions of dollars on chip development and production. The AI chip ChatGPT developed by major technology giants has exploded in popularity, and major manufacturers have launched a chip competition. According to reports from foreign media The Information and other sources, these three major manufacturers have now launched or plan to release 8 server and AI chips for internal product development. , cloud server rental or both. "if you

It is reported that Realtek 5GbE wired network card chip RTL8126-CG has stability issues and will be postponed to next year

Aug 25, 2023 am 11:53 AM

It is reported that Realtek 5GbE wired network card chip RTL8126-CG has stability issues and will be postponed to next year

Aug 25, 2023 am 11:53 AM

According to news from this site on August 24, most technology manufacturers displayed some new or upcoming new products at Gamescom. For example, ASRock showed its "half-generation" updated version of the Z790 motherboard. These new motherboards use The RTL8125-BG chip is used instead of the RTL8126-CG used in the prototype at the Computex show in June. According to Dutch media Tweakers, a number of motherboard manufacturers participating in Gamescom revealed that although Realtek's 5GbE wired network card chip RTL8126-CG is cheaper, it will not be installed on motherboards launched this fall due to stability issues. Realtek is said to be fixing this type of issue, but they won't be able to fix it before the new motherboards come out this fall