Technology peripherals

Technology peripherals

AI

AI

How to treat urban 'thrombosis”? Robot+ is coming, and many pipeline dredging robot companies have applied to participate

How to treat urban 'thrombosis”? Robot+ is coming, and many pipeline dredging robot companies have applied to participate

How to treat urban 'thrombosis”? Robot+ is coming, and many pipeline dredging robot companies have applied to participate

More and more urban constructions must pay attention to not only "face", but also "lizi".

From the sewage manhole cover downwards, there is a city's underground pipe network. The sewer pipes are as black as ink and have a continuous stench. Most people are afraid of them, but they are also an important infrastructure and "blood vessels" of a city. If it is not cleaned up for a long time, it will not only affect the water quality of the river, but also cause congestion and damage. At present, underground pipeline maintenance, as an important step in managing the city's "blood vessels", has begun to gradually move towards robot intelligence.

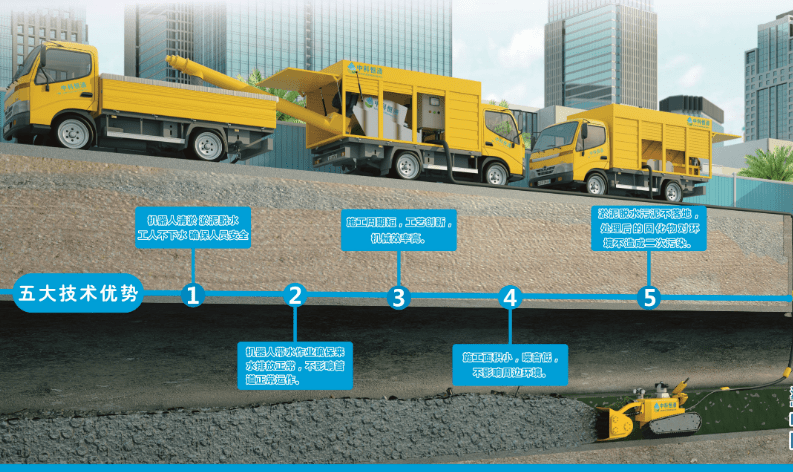

Urban underbelly is like an 'underground battlefield' for river management. The terrain environment is very complex. For example, in small pipelines, front-line workers work in small working spaces. Some pipelines even contain toxic gases, and workers need to wear protective gear. It can only be carried out after being equipped with a manual sewage suction truck. The construction risk is very high and the efficiency is low. Most of the cleaned sludge contains high water content, which leads to higher costs for subsequent transportation and treatment of the bottom sludge.

Therefore, dredging robots have also been subdivided into multiple uses such as detection, dredging, transportation, and repair. With different functional characteristics, they are used in large and small rivers, lakes, and park landscape waterways in cities. , sewage pipes, box culverts, tunnels, hidden culverts, rainwater and sewage diversion pipes and other scenarios. has also begun to be used for septic tanks, sewage tanks, sedimentation tanks, pond dredging, river dredging, municipal box culvert dredging, reservoir clearing and expansion, deep water area dredging, storage tank cleaning and dredging, water Warehouse desilting, drainage ditch dredging and other fields.

The following introduces the robot products of several typical companies.

▍Zhongkeheng dredging robot

Zhongke Hengqing was registered and established in December 2019. The company is located in Kaiyang Intelligent Manufacturing Industrial Park. It is currently able to provide one-stop solutions for underwater sludge cleaning in various urban drainage pipe networks. And it has achieved great results in the development of robot technology and complete sets of equipment. In 2021, Zhongke Hengqing has applied for 35 patents, including 7 invention patents. In terms of patent holdings, it is the leading enterprise in the research and development of environmentally friendly desilting robots.

The dredging robot independently developed by Zhongke Hengqing is mainly composed of a mud taking system, an underwater walking system, an imaging system, a lighting system, a detection system, a control system, etc. It is also equipped with a variety of intelligent monitoring devices and Human-computer interaction system can realize remote intelligent operation of equipment. Zhongke Hengqing’s dredging robots generally adopt crawler chassis, which can be well adapted to a variety of complex environments, with both mobile passing capabilities and operating efficiency. In addition, Zhongke Hengqing masters the core technology of the robot’s three-dimensional imaging system. , its complete set of intelligent tubular underwater dredging robots can be well used in non-stop water dredging operations for large-diameter pipelines, and has good advantages in accuracy, timeliness, and sludge disposal efficiency.

developed by Zhongke Hengqing often has operating arms at both front and rear ends. The mud removal device at one end has the functions of forced crushing and anti-winding, and can remove stones, branches, Shred garbage such as rags into smaller sizes. The multifunctional robotic arm at the other end is equipped with an impact breaker, which can be used to deal with blockages and hardening; the robotic arm is in a contracted state during the robot's dredging operation, which ensures the robot's operating balance and mobility stability.

At the same time, this robot can also be equipped with aintegrated shearing and grabbing manipulator, used to handle steel bars, tree roots and grab debris, or a full-degree-of-freedom nozzle to spray cement mortar for repairs Protective pipes are damaged or collapsed, and can be used in scenarios such as round pipes, square culverts, sewage pumping stations, and domestic sewage sedimentation tanks.

Environmental adaptability is an area that Zhongke Hengqing desilting robot attaches great importance to. Its all-terrain robot can also adopt a spiral propulsion structure. In addition to being suitable for water, it can also be applied to shallow water silt and sand. At the same time, modularization of work tools is also an important direction of its development. The robot is equipped with a ring-scanning sonar imaging system and can also detect and scan underwater material structures, and can calculate the underwater three-dimensional model through terminal software; equipped with a ring-scanning lidar imaging system, it can detect and scan water-based material structures, and can calculate and calculate the underwater three-dimensional model through terminal software. Three-dimensional model; equipped with a muddy water high-definition imaging system to assist human intervention in operating the robot; equipped with ultraviolet light curing and repair UV-CIPP technology, it can transform into a structural defect pipeline repair robot, improving the versatility of the product.Currently, Zhongke Hengqing is also trying to develop more accessories such as buoyancy cables and periscopes to improve the environmental adaptability of the product.

At the same time, it uses systematic capabilities to realize the digitalization, visualization, precision and modeling of the drainage system. , improve work accuracy and efficiency.

▍Alfa desilting robot

The dredging robot developed by Xi'an Alpha Industrial Co., Ltd. is also very typical. Its product chassis not only has crawler type and screw propelling type, but is also suitable for swamps, wetlands, tidal flats, oil fields, mines and other environments The floating chassis can be equipped with a hydraulically driven slurry pump in the middle. With its special dredging parts, realizes top-down operation and is more suitable for amphibious situations such as moat dredging and special-shaped pipeline dredging. Work.

Since Alpha Industrial’s dredging robot is driven by hydraulic pressure, its overall power and load capacity are quite advantageous, and the stability of the control system is very superior, which makes its robots often directly equipped with operating equipment in addition to With pumping equipment and a robot equipped with a sewage suction head, sludge and sewage removal can be quickly and simultaneously eliminated, saving the cost of a piece of equipment and manpower.

control the working attitude and efficiency of the working end, and the robot can work in an integrated manner during the movement. First, the working end controls The sludge and sediment at the location are dispersed, mixed, cut, collected, crushed, etc., and then directly extracted and transported by the extraction device or robot. Finally, the sludge and sediment are transported to post-processing equipment for classification, separation, crushing, Filtration and resource recycling, etc.

The hydraulic system also bringsthe advantages of safety, reliability, efficiency, environmental protection, mobility and flexibility to the equipment. It can realize one-stop processing of sludge in limited space. The robot is also highly automated and intelligent, supporting remote control and wire Control, compatible with 5G monitoring and control, unmanned remote control, Due to the high stability of the equipment, there is no need to stop work, stop production, stop operation, and drain water during the operation. The equipment is also highly reusable, and the overall cost is greatly reduced.

▍QISI Environmental Pipeline Dredging Robot

The pipeline dredging robot independently developed by Hunan Qisi Environmental Protection Co., Ltd. emphasizes the real-time monitoring and autonomous operation capabilities of pipeline sewage problems, hoping to realize the automation and unmanned problem of sewer dredging.

Qisi Environmental Protection, as a "specialized, special and innovative" small giant enterprise, focuses on the one-stop treatment process of underwater sludge in limited spaces and the research and development of robot dredging equipment. It is used in domestic waste processing, drainage pipe network dredging and maintenance, and drainage. It has a number of R&D efforts in areas such as smart operation and maintenance of pipe networks.From the product point of view, Qisi’s environmentally friendly robot

is equipped with high-definition cameras, sonar and other sensors.is like the “eyes” of the robot, which can “listen in all directions” to detect hidden situations and conditions from multiple angles. Working conditions, comprehensive detection of hidden culvert silt status and obstacle avoidance. At the same time, Qisi Environmental Protection has also developed a tailor-made intelligent control system for the underwater dredging robot , which allows the robot to operate in dark and narrow corners. , ramps are as smooth as walking on flat ground, and can be controlled freely, effectively ensuring the robot's ability to cope with complex operating conditions.

It is reported that this system makes the robot more intelligent. It can not only accurately grasp the hidden culvert operation situation in real time, but also match and compare the on-site conditions.

It is reported that this system makes the robot more intelligent. It can not only accurately grasp the hidden culvert operation situation in real time, but also match and compare the on-site conditions.

allows the robot to effectively respond to sudden changes in river conditions. When this robot enters the pipeline, technicians need to give instructions in the ground control room, understand the robot's status and environment through the console, and manually control the robot to remove silt. Once the technician confirms that the robot is running smoothly, he only needs to click the operation button, and the robot can automatically desilt and return the hidden culvert according to the preset settings.

In summary,

This robot has three characteristics: high efficiency, low cost, and high safety factor.No matter it encounters hard mud, domestic garbage, construction waste, or whether the river is full of Whether it is water or semi-water, deep or shallow, the robot can handle it and has stronger and efficient adaptation characteristics.

▍Conclusion and the future With the rapid development of my country's economy and the continuous improvement of residents' living standards, the discharge of industrial and agricultural wastewater and domestic sewage has increased year by year. The issue of urban river pollution control has attracted more and more managers' attention. However, since pipeline dredging and maintenance are mostly business activities dominated by government procurement, which require multiple qualifications such as municipal public engineering construction and environmental protection engineering, most of the market has been transformed by traditional environmental protection companies, and the subsequent monopoly is strong. In addition to the companies introduced above, there are currently Ningbo Guangqiang Robot Technology Co., Ltd., Shanghai Chenghong Pipeline Robot Co., Ltd., Beijing Hengtong Guosheng Environmental Management Co., Ltd., Harbin Institute of Technology Robot Group, Wuhan Qiyu Tianxia Environmental Technology Co., Ltd. and other companies are conducting research and development and marketization of pipeline-related robots. There are also universities such as Tsinghua University that are independently developing products in more subdivided fields such as automatic sewer dredging robots. In the future, they are expected to further solve management and cleaning problems in different areas such as civil and municipal use. In order to meet the needs of long-distance oil and gas pipeline transportation and automatic cleaning and inspection, the United States, Britain, France, Japan and other countries have begun to develop pipeline robots. Due to the limited space and complex conditions of underground pipelines, there has been a clear demand for more flexible and reliable intelligent robots. More and more dredging robots have been unveiled and rapidly applied. Intelligence will become a key part of solving the problem of underground pipeline network maintenance. At present, this field is still a sunrise industry and needs more young people to join.

The above is the detailed content of How to treat urban 'thrombosis”? Robot+ is coming, and many pipeline dredging robot companies have applied to participate. For more information, please follow other related articles on the PHP Chinese website!

Hot AI Tools

Undresser.AI Undress

AI-powered app for creating realistic nude photos

AI Clothes Remover

Online AI tool for removing clothes from photos.

Undress AI Tool

Undress images for free

Clothoff.io

AI clothes remover

Video Face Swap

Swap faces in any video effortlessly with our completely free AI face swap tool!

Hot Article

Hot Tools

Notepad++7.3.1

Easy-to-use and free code editor

SublimeText3 Chinese version

Chinese version, very easy to use

Zend Studio 13.0.1

Powerful PHP integrated development environment

Dreamweaver CS6

Visual web development tools

SublimeText3 Mac version

God-level code editing software (SublimeText3)

Hot Topics

The second generation Ameca is here! He can communicate with the audience fluently, his facial expressions are more realistic, and he can speak dozens of languages.

Mar 04, 2024 am 09:10 AM

The second generation Ameca is here! He can communicate with the audience fluently, his facial expressions are more realistic, and he can speak dozens of languages.

Mar 04, 2024 am 09:10 AM

The humanoid robot Ameca has been upgraded to the second generation! Recently, at the World Mobile Communications Conference MWC2024, the world's most advanced robot Ameca appeared again. Around the venue, Ameca attracted a large number of spectators. With the blessing of GPT-4, Ameca can respond to various problems in real time. "Let's have a dance." When asked if she had emotions, Ameca responded with a series of facial expressions that looked very lifelike. Just a few days ago, EngineeredArts, the British robotics company behind Ameca, just demonstrated the team’s latest development results. In the video, the robot Ameca has visual capabilities and can see and describe the entire room and specific objects. The most amazing thing is that she can also

After 2 months, the humanoid robot Walker S can fold clothes

Apr 03, 2024 am 08:01 AM

After 2 months, the humanoid robot Walker S can fold clothes

Apr 03, 2024 am 08:01 AM

Editor of Machine Power Report: Wu Xin The domestic version of the humanoid robot + large model team completed the operation task of complex flexible materials such as folding clothes for the first time. With the unveiling of Figure01, which integrates OpenAI's multi-modal large model, the related progress of domestic peers has been attracting attention. Just yesterday, UBTECH, China's "number one humanoid robot stock", released the first demo of the humanoid robot WalkerS that is deeply integrated with Baidu Wenxin's large model, showing some interesting new features. Now, WalkerS, blessed by Baidu Wenxin’s large model capabilities, looks like this. Like Figure01, WalkerS does not move around, but stands behind a desk to complete a series of tasks. It can follow human commands and fold clothes

How can AI make robots more autonomous and adaptable?

Jun 03, 2024 pm 07:18 PM

How can AI make robots more autonomous and adaptable?

Jun 03, 2024 pm 07:18 PM

In the field of industrial automation technology, there are two recent hot spots that are difficult to ignore: artificial intelligence (AI) and Nvidia. Don’t change the meaning of the original content, fine-tune the content, rewrite the content, don’t continue: “Not only that, the two are closely related, because Nvidia is expanding beyond just its original graphics processing units (GPUs). The technology extends to the field of digital twins and is closely connected to emerging AI technologies. "Recently, NVIDIA has reached cooperation with many industrial companies, including leading industrial automation companies such as Aveva, Rockwell Automation, Siemens and Schneider Electric, as well as Teradyne Robotics and its MiR and Universal Robots companies. Recently,Nvidiahascoll

The first robot to autonomously complete human tasks appears, with five fingers that are flexible and fast, and large models support virtual space training

Mar 11, 2024 pm 12:10 PM

The first robot to autonomously complete human tasks appears, with five fingers that are flexible and fast, and large models support virtual space training

Mar 11, 2024 pm 12:10 PM

This week, FigureAI, a robotics company invested by OpenAI, Microsoft, Bezos, and Nvidia, announced that it has received nearly $700 million in financing and plans to develop a humanoid robot that can walk independently within the next year. And Tesla’s Optimus Prime has repeatedly received good news. No one doubts that this year will be the year when humanoid robots explode. SanctuaryAI, a Canadian-based robotics company, recently released a new humanoid robot, Phoenix. Officials claim that it can complete many tasks autonomously at the same speed as humans. Pheonix, the world's first robot that can autonomously complete tasks at human speeds, can gently grab, move and elegantly place each object to its left and right sides. It can autonomously identify objects

Cloud Whale Xiaoyao 001 sweeping and mopping robot has a 'brain'! | Experience

Apr 26, 2024 pm 04:22 PM

Cloud Whale Xiaoyao 001 sweeping and mopping robot has a 'brain'! | Experience

Apr 26, 2024 pm 04:22 PM

Sweeping and mopping robots are one of the most popular smart home appliances among consumers in recent years. The convenience of operation it brings, or even the need for no operation, allows lazy people to free their hands, allowing consumers to "liberate" from daily housework and spend more time on the things they like. Improved quality of life in disguised form. Riding on this craze, almost all home appliance brands on the market are making their own sweeping and mopping robots, making the entire sweeping and mopping robot market very lively. However, the rapid expansion of the market will inevitably bring about a hidden danger: many manufacturers will use the tactics of sea of machines to quickly occupy more market share, resulting in many new products without any upgrade points. It is also said that they are "matryoshka" models. Not an exaggeration. However, not all sweeping and mopping robots are

The humanoid robot can do magic, let the Spring Festival Gala program team find out more

Feb 04, 2024 am 09:03 AM

The humanoid robot can do magic, let the Spring Festival Gala program team find out more

Feb 04, 2024 am 09:03 AM

In the blink of an eye, robots have learned to do magic? It was seen that it first picked up the water spoon on the table and proved to the audience that there was nothing in it... Then it put the egg-like object in its hand, then put the water spoon back on the table and started to "cast a spell"... …Just when it picked up the water spoon again, a miracle happened. The egg that was originally put in disappeared, and the thing that jumped out turned into a basketball... Let’s look at the continuous actions again: △ This animation shows a set of actions at 2x speed, and it flows smoothly. Only by watching the video repeatedly at 0.5x speed can it be understood. Finally, I discovered the clues: if my hand speed were faster, I might be able to hide it from the enemy. Some netizens lamented that the robot’s magic skills were even higher than their own: Mag was the one who performed this magic for us.

Ten humanoid robots shaping the future

Mar 22, 2024 pm 08:51 PM

Ten humanoid robots shaping the future

Mar 22, 2024 pm 08:51 PM

The following 10 humanoid robots are shaping our future: 1. ASIMO: Developed by Honda, ASIMO is one of the most well-known humanoid robots. Standing 4 feet tall and weighing 119 pounds, ASIMO is equipped with advanced sensors and artificial intelligence capabilities that allow it to navigate complex environments and interact with humans. ASIMO's versatility makes it suitable for a variety of tasks, from assisting people with disabilities to delivering presentations at events. 2. Pepper: Created by Softbank Robotics, Pepper aims to be a social companion for humans. With its expressive face and ability to recognize emotions, Pepper can participate in conversations, help in retail settings, and even provide educational support. Pepper's

Is robotic IoT the future of manufacturing?

Mar 01, 2024 pm 06:10 PM

Is robotic IoT the future of manufacturing?

Mar 01, 2024 pm 06:10 PM

Robotic IoT is an emerging development that promises to bring together two valuable technologies: industrial robots and IoT sensors. Will the Internet of Robotic Things become mainstream in manufacturing? What is the Internet of Robotic Things? The Internet of Robotic Things (IoRT) is a form of network that connects robots to the Internet. These robots use IoT sensors to collect data and interpret their surroundings. They are often combined with various technologies such as artificial intelligence and cloud computing to speed up data processing and optimize resource utilization. The development of IoRT enables robots to sense and respond to environmental changes more intelligently, bringing more efficient solutions to various industries. By integrating with IoT technology, IoRT can not only realize autonomous operation and self-learning, but also