Technology peripherals

Technology peripherals

AI

AI

Ling Yunguang: Machine vision + AI innovation helps 'intelligent' manufacturing of lithium batteries

Ling Yunguang: Machine vision + AI innovation helps 'intelligent' manufacturing of lithium batteries

Ling Yunguang: Machine vision + AI innovation helps 'intelligent' manufacturing of lithium batteries

Recently, the 2023 Machine Vision Technology and Application Summit hosted by GaoGong Robot and GaoGong Robot Industry Research Institute (GGII) was grandly held in Shenzhen. Ling Yunguang delivered a keynote speech on "Innovative Vision Solutions Light up Intelligent Manufacturing" and won the "2023 Machine Vision Industry Chain Top 30" award.

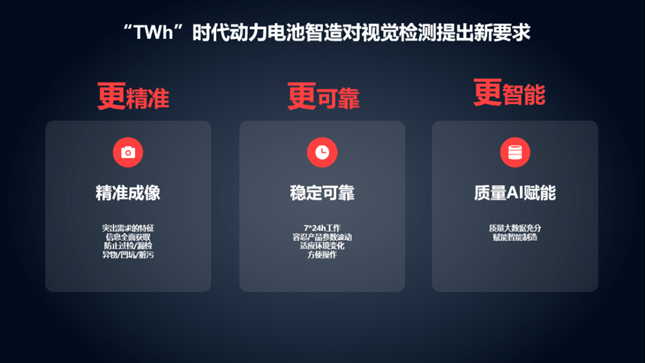

Yao Mingru, Director of Lingyun Optical Solutions, introduced that the needs of intelligent manufacturing in the "TWh" era are intelligent production, intelligent inspection, and intelligent management; the world-class problems in the field of industrial vision are unstable defect detection and "saving" The "people" strategy is not obvious and the value of data is difficult to reflect; the intelligent manufacturing of power batteries in the "TWh" era puts forward new requirements for visual inspection that are more accurate, more reliable, and more intelligent. By using big data and cloud computing technology, future industrial production will be data-based, knowledge-based and intelligent, which will greatly improve production and quality management levels.

The market continues to improve, new demands for intelligent manufacturing in the TWh era

In recent years, driven by the global net-zero carbon emission goal, the road transportation field has accelerated the electrification transformation, and electric vehicle power batteries are moving from GWh manufacturing to TWh era intelligent manufacturing. Under the new industry cycle, power battery companies have put forward higher requirements:

• High-speed production: Taking prismatic batteries as an example, the production speed requirement is moving towards 40PPM;

• Control costs: production costs should be reduced by 42%;

• Lean management: production efficiency should be increased by 50%;

• Quality requirements: The defect rate is reduced from ppm level to ppb level.

These requirements are the core of intelligent manufacturing of power batteries. The industry is developing rapidly, calling for the acceleration of intelligent manufacturing empowerment.

Ling Yunguang: Machine vision helps intelligent manufacturing of lithium batteries

"In 2000, Ling Yunguang cooperated with the Shanghai Banknote Printing Factory to develop a system that can conduct online quality inspection of large-format RMB gravure printing, thus starting the road to machine vision research and development." In the course of more than 20 years of development, Ling Yunguang has continuously increased investment in research and development, gradually accumulated technical capabilities such as algorithm platforms and GMQM quality management systems, and has won one first prize for national technological invention and two national scientific and technological progress awards. second prize. Facing the new demand for intelligent manufacturing in the lithium battery industry, Ling Yunguang used its own strength to submit a "machine vision AI" solution, using a more precise, more accurate, more stable and smarter method to solve the problem of defect detection in the industrial vision field. The problems of stability, lack of obvious "people-saving" strategy, and difficulty in reflecting the value of data will help the intelligent manufacturing of lithium batteries.

More precise: precise imaging

The premise of quality inspection is that the visual system should photograph various defects. Lingyun Optical Vision Inspection System has high-precision defect identification capabilities and can accurately capture pinholes, bright spots and other tiny defects. The detection accuracy can reach 0.05*0.05mm and can be 100% identified. Innovative double-sided leakage identification technology can identify single and double-sided leakage defects at the same time. In terms of stereoscopic imaging, the 2.5D system is used to take defect photos with 3D information, which can identify wrinkles, bulges, pits and other defects, with a classification accuracy higher than 99%. In a highly vibrating environment, the imaging is accurate without fear of jitter. After testing the vibration amplitude and frequency, the optimal installation point solution is obtained through anti-seismic simulation design and verification. In highly vibrating environments such as die cutting, winding, welding, and cell appearance inspection, The detection accuracy can be guaranteed to be 0.02-0.05mm.

More accurate: defect identification

Scientific measurement is the guarantee of quality management. Classification accuracy is determined by both imaging effects and deep learning. In order to ensure the scientific nature of quality management, Lingyunguang has developed a series of AI-based intelligent detection and classification technologies. These technologies can realize functions such as defect detection, intelligent classification, interference classification, and over-inspection suppression, and can accurately evaluate and classify The accuracy rate provides a strong guarantee for quality management.

More stable: stable and reliable

Full representation imaging system needs to cooperate with high-speed embedded edge computing processing platform to take advantage of it. Lingyun Optical high-speed embedded edge computing processing platform uses parallel pipeline computing and deep learning traditional algorithm fusion computing to achieve an image throughput of more than 2GB/s. The throughput is equivalent to the throughput of four traditional industrial computers, and high computing power returns can be achieved with low investment.

In addition, Lingyun Optical has realized the localization of core components in the entire process from image acquisition to image processing, including CMOS chips, cameras, lenses, processors, boards, light sources, etc., and can also quickly carry out various application scenarios. Customized development and ensuring a stable supply chain system.

At the same time, Lingyun Optical reserves the self-developed algorithm framework VisionWARE and continues to update and optimize it. It can select the required modules or customize development according to actual application scenarios to achieve efficiency improvements.

Smarter: Quality AI Empowerment

Lingyun Guang’s machine vision quality system uses big data and cloud computing technology to realize the digitalization, knowledgeization and intelligence of industrial production, and improve the level of production and quality management. By establishing a human vision model, the quality standard machine can formulate scientific and effective quality standards for equipment based on human subjective qualitative standards. Using the GMQM quality management system, one-click unified standards can be easily realized throughout the entire production line and the quality standards of different production lines can be coordinated. GMQM real-time quality monitoring and analysis system can be applied to visual inspection and quality inspection to provide product quality assurance, quality management, quality improvement and quality cost optimization.

Machine vision AI helps industrial artificial intelligence truly come to fruition

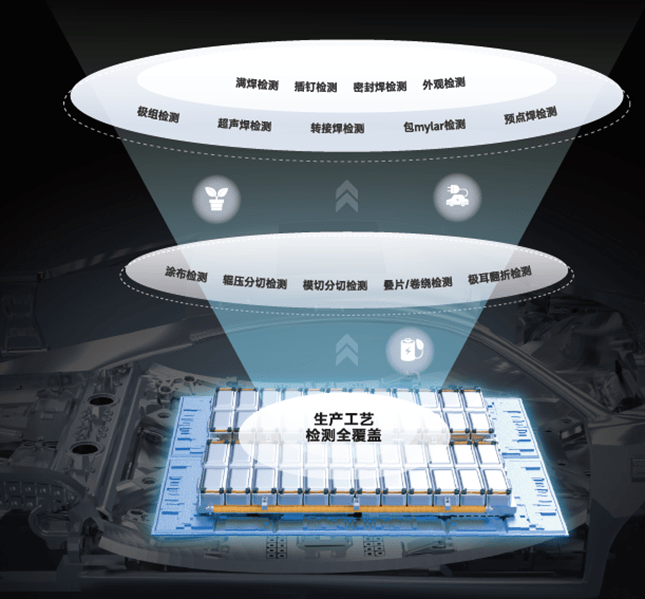

Since 2012, artificial intelligence technology based on deep learning has been widely used and re-innovated in industrial application scenarios. Facing the new demand for intelligent manufacturing in the lithium battery industry, Lingyunguang has comprehensively assisted the development of intelligent manufacturing in the new energy industry. Related vision system products with fully independent intellectual property rights have been widely used in the upstream and downstream production lines of the lithium battery industry.

2023 Machine Vision Industry Chain TOP30

At the meeting, the "2023 Machine Vision Industry Chain TOP30" was officially announced. Ling Yunguang ranked on the list with its advanced technical strength and significant market influence in the machine vision industry.

In the face of new changes and new demands in the lithium battery industry, Lingyunguang will use its solid technical strength to deeply explore customer needs in the field of lithium battery machine vision, help customers achieve the goal of zero complaints with innovative products and solutions, and assist machine vision and intelligent manufacturing. Industry flexible upgrade!

The above is the detailed content of Ling Yunguang: Machine vision + AI innovation helps 'intelligent' manufacturing of lithium batteries. For more information, please follow other related articles on the PHP Chinese website!

Hot AI Tools

Undresser.AI Undress

AI-powered app for creating realistic nude photos

AI Clothes Remover

Online AI tool for removing clothes from photos.

Undress AI Tool

Undress images for free

Clothoff.io

AI clothes remover

Video Face Swap

Swap faces in any video effortlessly with our completely free AI face swap tool!

Hot Article

Hot Tools

Notepad++7.3.1

Easy-to-use and free code editor

SublimeText3 Chinese version

Chinese version, very easy to use

Zend Studio 13.0.1

Powerful PHP integrated development environment

Dreamweaver CS6

Visual web development tools

SublimeText3 Mac version

God-level code editing software (SublimeText3)

Hot Topics

1389

1389

52

52

Promoting the digital upgrading of the industry, Qianjiang Robot builds an intelligent manufacturing ecosystem

Sep 24, 2023 am 10:13 AM

Promoting the digital upgrading of the industry, Qianjiang Robot builds an intelligent manufacturing ecosystem

Sep 24, 2023 am 10:13 AM

Automation, intelligence, and digital intelligence are the development directions of traditional manufacturing. As one of the key equipment for automated production lines, intelligent logistics, human-machine collaboration, and customized production, robots play a key role in the change from traditional manufacturing to intelligent manufacturing. Aistar Qianjiang Robot has covered four major business segments: core components of industrial robots, complete robots, industrial software, and intelligent manufacturing system integration. At the 23rd China International Industrial Expo held from September 19th to 23rd, Aistar Qianjiang Robot Jiang Robot joins hands with a number of affiliated companies to focus on industrial automation, industrial robots and intelligent manufacturing, providing users with high-end, intelligent, and unmanned industrial complete solutions. Chen Helin, Chairman of ASD Co., Ltd. and Director of Zhejiang Qianjiang Robot Co., Ltd. said,

New technology launched, IDEA Research Institute released T-Rex model, allowing users to select 'Prompt' prompts directly on the image

Nov 24, 2023 am 08:10 AM

New technology launched, IDEA Research Institute released T-Rex model, allowing users to select 'Prompt' prompts directly on the image

Nov 24, 2023 am 08:10 AM

Following the popularity of GroundedSAM, the IDEA Research Institute team returns with a new work: the new visual prompt (VisualPrompt) model T-Rex, which uses pictures to recognize pictures and can be used right out of the box, opening up a new world of open set detection! Pull the frame, check and complete! At the just-concluded 2023 IDEA conference, Shen Xiangyang, founding chairman of the IDEA Research Institute and foreign academician of the National Academy of Engineering, demonstrated a new target detection experience based on visual cues and released the model laboratory (playground) of the new visual cues model T-Rex ), InteractiveVisualPrompt (iVP), which set off a wave of trial climaxes on site. On iVP, users can personally unlock “a

How to implement intelligent manufacturing system through C++ development?

Aug 26, 2023 pm 07:27 PM

How to implement intelligent manufacturing system through C++ development?

Aug 26, 2023 pm 07:27 PM

How to implement intelligent manufacturing system through C++ development? With the development of information technology and the needs of the manufacturing industry, intelligent manufacturing systems have become an important development direction of the manufacturing industry. As an efficient and powerful programming language, C++ can provide strong support for the development of intelligent manufacturing systems. This article will introduce how to implement intelligent manufacturing systems through C++ development and give corresponding code examples. 1. Basic components of an intelligent manufacturing system An intelligent manufacturing system is a highly automated and intelligent production system. It mainly consists of the following components:

The future of automobiles: embracing smart manufacturing

Sep 25, 2023 pm 05:29 PM

The future of automobiles: embracing smart manufacturing

Sep 25, 2023 pm 05:29 PM

The emergence of intelligent manufacturing technology has had a significant impact on the automobile manufacturing industry. First, smart manufacturing uses automation, the Internet of Things (IoT), digital processes and sustainable practices. The final factors for having a smart manufacturing unit are efficiency, production optimization, traceability, quick turnaround during downtime, safer working conditions and responsible manufacturing. The future of automobiles: Embracing intelligent manufacturing Many advanced technologies have realized the concept of intelligent manufacturing in the workshop, such as: intelligent manufacturing controlled by the Internet of Things, cloud computing, artificial intelligence, and machine learning. The Internet of Things is the core of intelligent manufacturing and is the link between the automobile production environment and The backbone of a wide range of devices, sensors and machines. IoT devices collect and exchange data and monitor and control processes in real time. This connection facilitates seamless communication between machines, allowing them to

How to implement machine vision algorithms and object recognition in C++?

Aug 26, 2023 pm 09:17 PM

How to implement machine vision algorithms and object recognition in C++?

Aug 26, 2023 pm 09:17 PM

How to implement machine vision algorithms and object recognition in C++? Introduction: With the continuous development and application of artificial intelligence, machine vision technology has been widely used in various fields, such as autonomous driving, security monitoring, medical imaging, etc. Among them, C++, as a widely used programming language, has the characteristics of high compilation efficiency and strong flexibility, and has gradually become the preferred language for the implementation of machine vision algorithms. This article will introduce how to implement machine vision algorithms and object recognition through C++, and attach code examples. I hope it can provide some help to readers.

What hardware does machine vision contain?

Apr 14, 2023 am 08:49 AM

What hardware does machine vision contain?

Apr 14, 2023 am 08:49 AM

As various industries begin to have widespread demands for industrial automation and intelligence using image and machine vision technology, machine vision has gradually begun to be applied in industrial sites. Driven by the government's favorable policies, the domestic machine vision industry is developing rapidly, and China is becoming one of the most active regions in the world for machine vision development. It is expected that the size of my country's machine vision market will reach 24.6 billion yuan by 2025. Let’s take a deeper look at machine vision. Machine vision is a comprehensive technology, including image processing, mechanical engineering technology, control, electric light source lighting, optical imaging, sensors, analog and digital video technology, computer software and hardware technology (image enhancement and analysis algorithms, image cards, I/O card, etc.). A typical machine vision application system includes image capture, light source system, image

Introduction to Java-based machine vision practices and methods

Jun 18, 2023 am 11:21 AM

Introduction to Java-based machine vision practices and methods

Jun 18, 2023 am 11:21 AM

With the continuous development of science and technology, machine vision technology has been widely used in various fields, such as industrial automation, medical diagnosis, security monitoring, etc. As a popular programming language, Java also has important applications in the field of machine vision. This article will introduce Java-based machine vision practices and related methods. 1. Application of Java in machine vision As a cross-platform programming language, Java has the advantages of cross-operating systems, easy maintenance, and high scalability. It has certain advantages for machine vision applications. Java

Hikvision Robotics: Empowering intelligent manufacturing of new energy vehicles in all scenarios

May 27, 2023 pm 04:14 PM

Hikvision Robotics: Empowering intelligent manufacturing of new energy vehicles in all scenarios

May 27, 2023 pm 04:14 PM

Advertisement | Click to view Hangzhou Hikvision Robot Co., Ltd. ("Hikvision Robot" for short) is a global provider of machine vision and mobile robot products and solutions. Its business focuses on the industrial Internet of Things, smart logistics and smart manufacturing, building an open The cooperative ecosystem provides services to users in the industrial and logistics fields, continues to promote intelligence with innovative technologies, and leads the intelligent manufacturing process. At present, Hikvision Robotics relies on four major mobile robot product lines: latent, moving/heavy-load, forklift, and bin, as well as two major software platforms: robot control system RCS and intelligent warehouse management system iWMS. Its business focuses on automobiles, new energy, and 3C electronics. , pharmaceutical and medical care, e-commerce retail and other sub-industry customers. The new energy automobile industry is a segmented industry that Hikvision Robotics attaches great importance to.