Under the combined influence of the acceleration of global industrial transformation, the trend of fewer people and policy tilts, robots, as general intelligent carriers for automation and unmanned applications, have effectively replaced traditional industry machinery with advantages such as improving work efficiency and reducing labor costs. Repeated, high-intensity, and difficult-to-recruit jobs are becoming more and more incremental.

As robot applications enter more scenarios and robots get rid of the limitations of mechanical fixed modes, the demand for intelligence, flexibility, and interaction becomes more and more common. Based on their respective advantages accumulated over many years in the fields of industrial robots and 3D machine vision, Peitian Robot and Tuyang Technology combine to create a hand-eye system with rapid and flexible deployment, convenient maintenance, and more innovative value at the level of product application and solution collaboration. Collaborative solutions can be implemented in batches in multi-industry and multi-scenario applications such as smart manufacturing, logistics and express delivery, and jointly bring practical service values such as cost reduction, efficiency improvement and quality improvement to end users.

Robot 3D vision, hand-eye correspondence is even more powerful

Peitian Robot is a solution provider focusing on industrial robots, core components and industry automation. The core components of the robot, including control systems, servo drives, servo motors, etc., are all independently developed, and have powerful core software technologies and algorithms. It can provide robot control system solutions, complete sets of flexible manufacturing equipment and systems, and automation solutions for the robot application industry. The company's industrial robot products have a load range of 3 to 280 kilograms and are used in batches in 3C, manufacturing, automobiles, rubber and plastic products, glass, food, medical engineering, machinery and other industries.

Percipio.XYZ is the world's leading 3D machine vision supplier, providing cost-effective 3D industrial cameras and supporting software for industrial and industrial applications. , jointly create a complete 3D vision industry solution and promote intelligent and automated upgrades in multiple industries.

Application Case/3D Vision Guided Standard Depalletizing

With cartons, turnover boxes, foam boxes, soft bags, etc. becoming indispensable daily logistics carriers in many industries, customers hope to use intelligent robot 3D vision to realize automated depalletizing and unpacking applications to improve depalletizing efficiency.

Difficulties in the implementation of limited customer sites, numerous SKUs, and material update iterations. Packaging boxes from different sources and uses have complex problems such as differences in size/packaging/arrangement (soft bags, transparent materials, reflective tape/tie, scattered stacking/stacked and blocked, etc.). At the same time, zero physical damage ensures the safety of the goods.

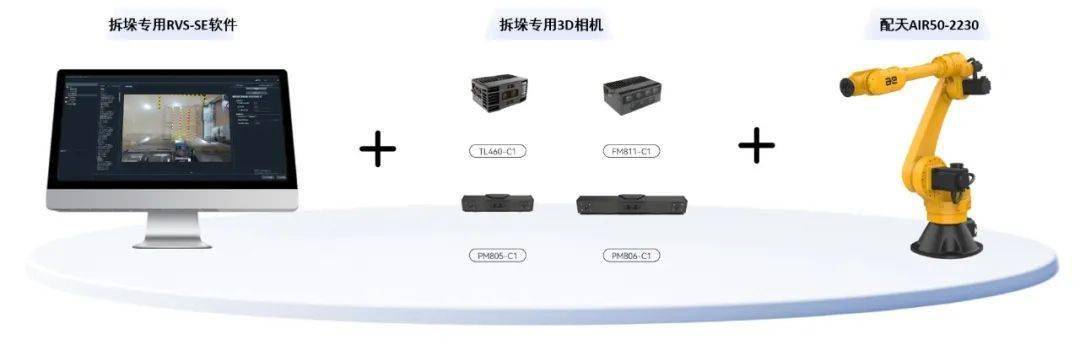

Project Introduction:Peitian Robot It is composed of visual software RVS-SE, which is based on deep learning technology and built-in super model. It eliminates the need for sample training, quickly obtains robot guidance information for cartons/soft packages, and does not require teaching programming. It can automatically plan the robot's operating trajectory and efficiently depalletize.

Core Components

Application Advantages

Intelligent path planning: Zero-collision movement, real-time adjustment of movement trajectories in the presence of complex interference (narrow space, cargo supports, pedestrians, etc.) to avoid material damage

Accurate and fast pick and place: Best Z-direction precision control ±3mm; visual processing per beat ≤2s (picture acquisition->calculation->output coordinates); accuracy reaches 99.9%

Agile deployment and operation: Standardized solution, installation and deployment can be completed quickly, no space modification is required, efficient deployment is quickly activated, and debugging and operation are simple

Low cost and high return: Higher cost performance, can intelligently and stably automatically complete long-term high-intensity work, replacing 1-3 laborers, and more long-term output benefits

Application Case/3D Vision Guided Workpiece Sorting

When the customer used manual sorting operations for cylindrical workpieces, the tedious and repetitive operations were long, the manual work was highly subjective and prone to fatigue, the accuracy was low, and it was unable to meet higher precision requirements, and there was material damage. , and one assembly line requires multiple inspectors, which further increases the factory’s labor costs.

The customer hopes to use 3D vision to guide the robot to automatically sort workpieces from the material frame through the transformation of the automated work station, and solve the problem of black light absorption, full frame loading, tight placement, cylinder positioning, and the collision between the fixture-material frame-workpiece etc. and ensure zero material damage, etc., to complete the rapid loading operation.

Project Introduction:Peitian Robot It is composed of visual software RVS-SE, which is based on deep learning technology and built-in super model. It eliminates the need for sample training, quickly obtains robot guidance information for cartons/soft packages, and does not require teaching programming. It can automatically plan the robot's operating trajectory and efficiently depalletize.

Core Components

Application Advantages

Intelligent path planning: Based on the movement path and obstacle avoidance strategy, it ensures accurate grabbing points and reasonably plans the movement path of the end effector to avoid collision situations and avoid material damage

Accurate and fast pick and place: Best Z-direction precision control ±1-2mm; visual processing per beat ≤3s (picture acquisition->calculation->output coordinates); accuracy reaches 99.9 %

Benefits of fewer people: Reduce work stations and personnel arrangements, reduce labor costs and management costs

Application case/3D visual guidance automatic package supply

With the booming development of global e-commerce shopping, the ultra-large sorting center model that processes millions of pieces/day orders has become increasingly popular. However, the traditional manual supply model has difficulty in recruitment, high labor costs, labor intensity, difficulty in management, and limited working hours. It is difficult to meet the objective demand for high sorting efficiency due to limited conditions. Automatic package supply has subsequently become a mainstream application in current e-commerce logistics package sorting.

Before the project, end customers mainly relied on manual methods to complete the supply and packaging of parts. It was difficult to recruit workers, consumed a lot of labor, was inefficient and costly, so they chose to introduce automated applications. Considering that the fully automatic supply package solution based on single-piece separation has complex structure, high on-site modification costs, large operating energy consumption (a large number of motors and belts), high difficulty in repairing abnormal situations, long input-output cycle and other uncertain risks, customers hope that It can realize automatic contract supply applications that are modular, low-cost, simple and fast to deploy, and convenient for management and maintenance while avoiding site modifications and interfering with on-site operations.

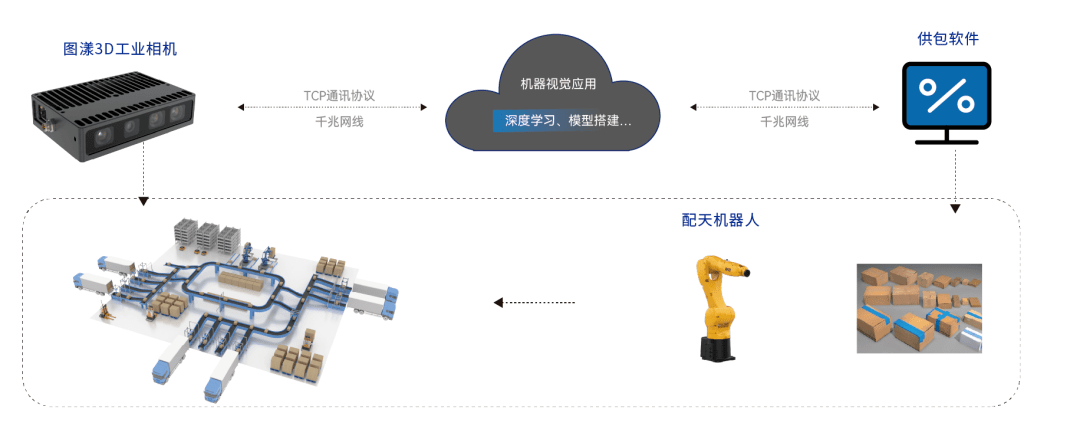

Project Introduction:Peitian Robot , a 3D industrial camera that replaces a single manual packaging application. It is modularly installed and activated with one click. It is small in size and requires minimal changes to the existing site. It has low power consumption and consumes almost no power when there is no package. The industrial grade meets all-weather continuous and stable operation. . In the event of an abnormality on a single packaging platform, the entire sorting line will not be shut down, and maintenance is simple and convenient.

Core Components

Application Advantages

Intelligent path planning: Zero-collision motion path planning strategy minimizes abnormal situations such as package damage and jamming, and reduces manual intervention

Full-time automation: Significantly improve the efficiency of package supply, achieve the goal of less-manned sorting operation mode and reduce costs and increase efficiency

Simple deployment, ready to install and use: Minimal site occupation, no space modification required, modular and maintenance-free, one-click activation

High cost performance, short investment payback period: Significantly reduce labor costs, with overall better procurement and use cost performance

Original statement: Please indicate the source when reprinting original articles,

Disclaimer: Some of the pictures in this article come from the Internet,

If there is any infringement, please contact us in time to make relevant corrections.

The above is the detailed content of Peitian Robot X Tuyang Technology | Efficient and precise hand-eye combination accelerates multi-scenario intelligent manufacturing upgrades. For more information, please follow other related articles on the PHP Chinese website!