Technology peripherals

Technology peripherals

AI

AI

A major breakthrough! Wuchang Shipbuilding uses welding robots for the first time in duplex stainless steel ship construction

A major breakthrough! Wuchang Shipbuilding uses welding robots for the first time in duplex stainless steel ship construction

A major breakthrough! Wuchang Shipbuilding uses welding robots for the first time in duplex stainless steel ship construction

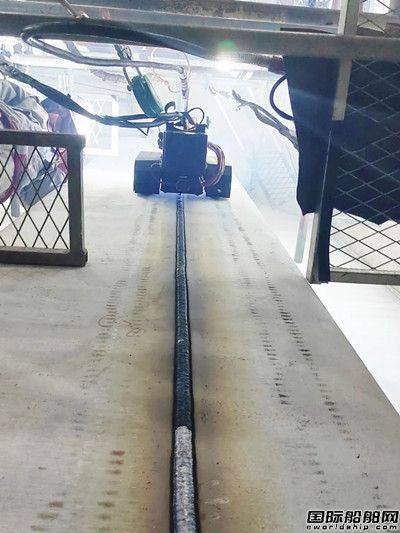

In order to achieve the goals of "improving quality", "reducing costs" and "increasing efficiency", the Wuchang Shipbuilding Ship Assembly Department of China State Shipbuilding Corporation has introduced new technology and equipment - trackless crawling welding robots.

Recently, the slipway workshop, support room and Wang Fei Skill Master Studio of the General Assembly Department debugged the equipment and welded the test plates, and made significant breakthroughs in the application of trackless crawling welding robots in the welding construction of duplex stainless steel ships. According to the manufacturer of the trackless crawling robot, this equipment has been exported to many foreign countries, but it is the first time it has been used in the welding of duplex stainless steel in China.

There are many difficulties in applying traditional manual welding technology to duplex stainless steel welding construction. In order to improve welding efficiency and welding quality, the general assembly department applied the trackless crawling welding robot to the vertical docking of the duplex stainless steel cargo tank of the 7200DWT chemical tanker No. 3. During the welding process, through continuous debugging and improvement of the trackless crawling welding robot, the construction personnel explored the optimal welding parameters for duplex stainless steel and overcame a series of technical difficulties.

The continuous advancement of welding robots in real ship welding work has the following advantages:

1. The trackless crawling welding robot can continuously weld with short interruption time and increase the welding efficiency by more than 50%;

2. The welding quality of the trackless crawling welding robot is stable. The welded seams can pass the PT test in one pass, and the overall construction efficiency is increased by more than 70%;

3. Anti-fall measures are designed and installed for trackless crawling robots to make the welding process safer;

4. The trackless crawling robot is equipped with a modified carbon dioxide welding machine, which can be used on the dock. The welding construction is simpler. After the improvement, only one person is needed to operate it, which effectively saves labor costs.

5. The welding robot can obtain the best shape of the weld by optimizing relevant parameters, greatly shortening the grinding time of vertical welds, and the pass rate of visual inspection of welds is nearly 100%, effectively reducing the grinding workload;

6. Reduce the labor intensity of the welder. The welder only needs to hold the remote control to make occasional corrections to the robot, and stay away from direct damage from arc light, smoke, spatter and toxic gases generated during the welding process, reducing the probability of occupational diseases.

For the first time, a welding robot has been applied on a real ship in the dual-phase stainless steel butt weld of the cargo tank of the 7200DWT chemical tanker No. 3. This marks a breakthrough in the application of robot welding in stainless steel ships and will contribute to the improvement of Wuchang Shipbuilding. The level of "three modernizations of shipbuilding" and the degree of informatization have a great promotion effect.

The above is the detailed content of A major breakthrough! Wuchang Shipbuilding uses welding robots for the first time in duplex stainless steel ship construction. For more information, please follow other related articles on the PHP Chinese website!

Hot AI Tools

Undresser.AI Undress

AI-powered app for creating realistic nude photos

AI Clothes Remover

Online AI tool for removing clothes from photos.

Undress AI Tool

Undress images for free

Clothoff.io

AI clothes remover

Video Face Swap

Swap faces in any video effortlessly with our completely free AI face swap tool!

Hot Article

Hot Tools

Notepad++7.3.1

Easy-to-use and free code editor

SublimeText3 Chinese version

Chinese version, very easy to use

Zend Studio 13.0.1

Powerful PHP integrated development environment

Dreamweaver CS6

Visual web development tools

SublimeText3 Mac version

God-level code editing software (SublimeText3)

Hot Topics

1387

1387

52

52

Top 5 GenAI Launches of February 2025: GPT-4.5, Grok-3 & More!

Mar 22, 2025 am 10:58 AM

Top 5 GenAI Launches of February 2025: GPT-4.5, Grok-3 & More!

Mar 22, 2025 am 10:58 AM

February 2025 has been yet another game-changing month for generative AI, bringing us some of the most anticipated model upgrades and groundbreaking new features. From xAI’s Grok 3 and Anthropic’s Claude 3.7 Sonnet, to OpenAI’s G

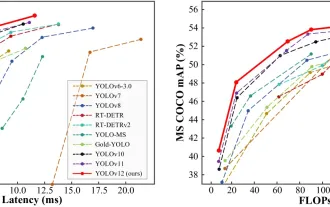

How to Use YOLO v12 for Object Detection?

Mar 22, 2025 am 11:07 AM

How to Use YOLO v12 for Object Detection?

Mar 22, 2025 am 11:07 AM

YOLO (You Only Look Once) has been a leading real-time object detection framework, with each iteration improving upon the previous versions. The latest version YOLO v12 introduces advancements that significantly enhance accuracy

Best AI Art Generators (Free & Paid) for Creative Projects

Apr 02, 2025 pm 06:10 PM

Best AI Art Generators (Free & Paid) for Creative Projects

Apr 02, 2025 pm 06:10 PM

The article reviews top AI art generators, discussing their features, suitability for creative projects, and value. It highlights Midjourney as the best value for professionals and recommends DALL-E 2 for high-quality, customizable art.

Is ChatGPT 4 O available?

Mar 28, 2025 pm 05:29 PM

Is ChatGPT 4 O available?

Mar 28, 2025 pm 05:29 PM

ChatGPT 4 is currently available and widely used, demonstrating significant improvements in understanding context and generating coherent responses compared to its predecessors like ChatGPT 3.5. Future developments may include more personalized interactions and real-time data processing capabilities, further enhancing its potential for various applications.

Best AI Chatbots Compared (ChatGPT, Gemini, Claude & More)

Apr 02, 2025 pm 06:09 PM

Best AI Chatbots Compared (ChatGPT, Gemini, Claude & More)

Apr 02, 2025 pm 06:09 PM

The article compares top AI chatbots like ChatGPT, Gemini, and Claude, focusing on their unique features, customization options, and performance in natural language processing and reliability.

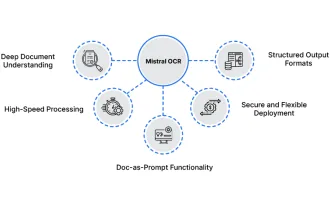

How to Use Mistral OCR for Your Next RAG Model

Mar 21, 2025 am 11:11 AM

How to Use Mistral OCR for Your Next RAG Model

Mar 21, 2025 am 11:11 AM

Mistral OCR: Revolutionizing Retrieval-Augmented Generation with Multimodal Document Understanding Retrieval-Augmented Generation (RAG) systems have significantly advanced AI capabilities, enabling access to vast data stores for more informed respons

Top AI Writing Assistants to Boost Your Content Creation

Apr 02, 2025 pm 06:11 PM

Top AI Writing Assistants to Boost Your Content Creation

Apr 02, 2025 pm 06:11 PM

The article discusses top AI writing assistants like Grammarly, Jasper, Copy.ai, Writesonic, and Rytr, focusing on their unique features for content creation. It argues that Jasper excels in SEO optimization, while AI tools help maintain tone consist

Getting Started With Meta Llama 3.2 - Analytics Vidhya

Apr 11, 2025 pm 12:04 PM

Getting Started With Meta Llama 3.2 - Analytics Vidhya

Apr 11, 2025 pm 12:04 PM

Meta's Llama 3.2: A Leap Forward in Multimodal and Mobile AI Meta recently unveiled Llama 3.2, a significant advancement in AI featuring powerful vision capabilities and lightweight text models optimized for mobile devices. Building on the success o