Robots produce robots! This picture...

Recently, the Shanghai Municipal Economic and Information Technology Commission issued a list of the first 10 "benchmark smart factories" in Shanghai. Jiading companies Aptiv Central Electric (Shanghai) Co., Ltd. and Shanghai New Star Robot Co., Ltd. were selected.

Today, with Xiaojia

Approaching Xinshida~

The New Star Robot Smart Factory is located in Malu Town, Jiading District. After it was put into production in December 2020, the company has continued to carry out technological innovation and management innovation to improve the level of intelligence.

In terms of technological innovation, the company uses the EMES system, the brain of the workshop, to provide execution and tracking of production plans and visual monitoring of all resource allocations, making the entire factory automated operation more intelligent; on the other hand, through vision, robots The integration of force control, flexible tooling and other technologies with robot applications has enabled robot production of robots for the first time in China.

In terms of the application of new technologies, based on the "Industrial Internet", the company has built three major systems: a flexible intelligent manufacturing system, an end-to-end intelligent logistics system, and a full-process traceable intelligent manufacturing system to achieve comprehensive integration of information flow and factories. interconnection of all elements within.

Smart factories deploy high-level automation systems such as robots, AGVs, three-dimensional warehouses and sorting systems, as well as EMES (Manufacturing Management System), WMS (Warehouse Management System), SRM (Supplier Management System), CRM (Sales Management System) ) and other digital and intelligent systems have significantly improved product quality and delivery capabilities.

In terms of process design, the New Star Robot Smart Factory can reduce production preparation hours by 30 minutes each time. Different structural models can be produced on the same line and quickly switched, and the production efficiency is increased by 20%; in terms of planning and scheduling, logistics personnel From the original 6 people to 3 people, the planning staff was reduced from the original 2 people to 1 person, and the corresponding operating staff was reduced by 50%; in terms of production operations, the operators were reduced from 6 to 2 people, and the production efficiency increased by 50%. Product throughput rate increased by 20%.

In the future, New Star will use Shanghai's benchmark smart factory as the basis to further strengthen automation, digitalization and intelligent transformation, lead the innovation of the industrial chain, and empower the manufacturing industry to develop to a high level.

learn more

Shanghai’s benchmark smart factories are selected by the Shanghai Economic and Information Technology Commission on the basis of national smart factories and Shanghai’s 100 smart factories through recommendations from various districts, preliminary evaluations by experts, on-site evaluations, defense reviews and list announcements. The 10 benchmark smart factories in Shanghai are specific measures for Shanghai to fully implement the smart factory pilot plan. Through benchmarking, it will promote the deep integration of the digital economy and the real economy.

Source: Shanghai Jiading

The above is the detailed content of Robots produce robots! This picture.... For more information, please follow other related articles on the PHP Chinese website!

Hot AI Tools

Undresser.AI Undress

AI-powered app for creating realistic nude photos

AI Clothes Remover

Online AI tool for removing clothes from photos.

Undress AI Tool

Undress images for free

Clothoff.io

AI clothes remover

Video Face Swap

Swap faces in any video effortlessly with our completely free AI face swap tool!

Hot Article

Hot Tools

Notepad++7.3.1

Easy-to-use and free code editor

SublimeText3 Chinese version

Chinese version, very easy to use

Zend Studio 13.0.1

Powerful PHP integrated development environment

Dreamweaver CS6

Visual web development tools

SublimeText3 Mac version

God-level code editing software (SublimeText3)

Hot Topics

1389

1389

52

52

Top 5 GenAI Launches of February 2025: GPT-4.5, Grok-3 & More!

Mar 22, 2025 am 10:58 AM

Top 5 GenAI Launches of February 2025: GPT-4.5, Grok-3 & More!

Mar 22, 2025 am 10:58 AM

February 2025 has been yet another game-changing month for generative AI, bringing us some of the most anticipated model upgrades and groundbreaking new features. From xAI’s Grok 3 and Anthropic’s Claude 3.7 Sonnet, to OpenAI’s G

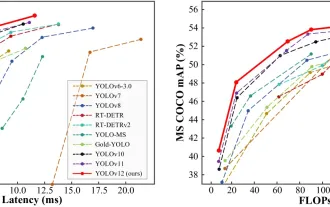

How to Use YOLO v12 for Object Detection?

Mar 22, 2025 am 11:07 AM

How to Use YOLO v12 for Object Detection?

Mar 22, 2025 am 11:07 AM

YOLO (You Only Look Once) has been a leading real-time object detection framework, with each iteration improving upon the previous versions. The latest version YOLO v12 introduces advancements that significantly enhance accuracy

Best AI Art Generators (Free & Paid) for Creative Projects

Apr 02, 2025 pm 06:10 PM

Best AI Art Generators (Free & Paid) for Creative Projects

Apr 02, 2025 pm 06:10 PM

The article reviews top AI art generators, discussing their features, suitability for creative projects, and value. It highlights Midjourney as the best value for professionals and recommends DALL-E 2 for high-quality, customizable art.

Is ChatGPT 4 O available?

Mar 28, 2025 pm 05:29 PM

Is ChatGPT 4 O available?

Mar 28, 2025 pm 05:29 PM

ChatGPT 4 is currently available and widely used, demonstrating significant improvements in understanding context and generating coherent responses compared to its predecessors like ChatGPT 3.5. Future developments may include more personalized interactions and real-time data processing capabilities, further enhancing its potential for various applications.

Best AI Chatbots Compared (ChatGPT, Gemini, Claude & More)

Apr 02, 2025 pm 06:09 PM

Best AI Chatbots Compared (ChatGPT, Gemini, Claude & More)

Apr 02, 2025 pm 06:09 PM

The article compares top AI chatbots like ChatGPT, Gemini, and Claude, focusing on their unique features, customization options, and performance in natural language processing and reliability.

Getting Started With Meta Llama 3.2 - Analytics Vidhya

Apr 11, 2025 pm 12:04 PM

Getting Started With Meta Llama 3.2 - Analytics Vidhya

Apr 11, 2025 pm 12:04 PM

Meta's Llama 3.2: A Leap Forward in Multimodal and Mobile AI Meta recently unveiled Llama 3.2, a significant advancement in AI featuring powerful vision capabilities and lightweight text models optimized for mobile devices. Building on the success o

Top AI Writing Assistants to Boost Your Content Creation

Apr 02, 2025 pm 06:11 PM

Top AI Writing Assistants to Boost Your Content Creation

Apr 02, 2025 pm 06:11 PM

The article discusses top AI writing assistants like Grammarly, Jasper, Copy.ai, Writesonic, and Rytr, focusing on their unique features for content creation. It argues that Jasper excels in SEO optimization, while AI tools help maintain tone consist

Guide to Uber's H3 for Spatial Indexing

Mar 22, 2025 am 10:54 AM

Guide to Uber's H3 for Spatial Indexing

Mar 22, 2025 am 10:54 AM

In today’s data-driven world, efficient geospatial indexing is crucial for applications ranging from ride-sharing and logistics to environmental monitoring and disaster response. Uber’s H3, a powerful open-source spat