Technology peripherals

Technology peripherals

AI

AI

Digital rehearsal, virtual factory construction! This top washing machine factory opens the door to the 'industrial metaverse'

Digital rehearsal, virtual factory construction! This top washing machine factory opens the door to the 'industrial metaverse'

Digital rehearsal, virtual factory construction! This top washing machine factory opens the door to the 'industrial metaverse'

In recent science fiction movies, the "parallel universe" that can be infinitely retraced has become one of the hot concepts. It has greatly expanded the creative space of literary and artistic works, and it also makes people wonder, if we have a way to exhaust all possibilities, can we find the "optimal solution" for the future?

Although this issue sounds very solemn and complicated, it is not unachievable in the fields of technological innovation and manufacturing. There is a famous saying in Silicon Valley called "fail fast." It does not refer to making mistakes, but it means that to achieve innovation, you need to learn quickly from failed experiments again and again, and finally form the most effective solution.

In China, as the first enterprise to explore intelligent manufacturing and the industrial Internet, the intelligent 5G mass customization virtual and real integration demonstration and verification platform created by COSMOPlat is also based on this thinking. With the mass customization model as the core, the platform integrates digital twins and real production lines. Enterprises can use the platform to carry out multi-technology cross-border integration integration testing, allowing digital information to replace physical entities for "rehearsal", thereby quickly building and Validate new technologies and solutions across different industries.

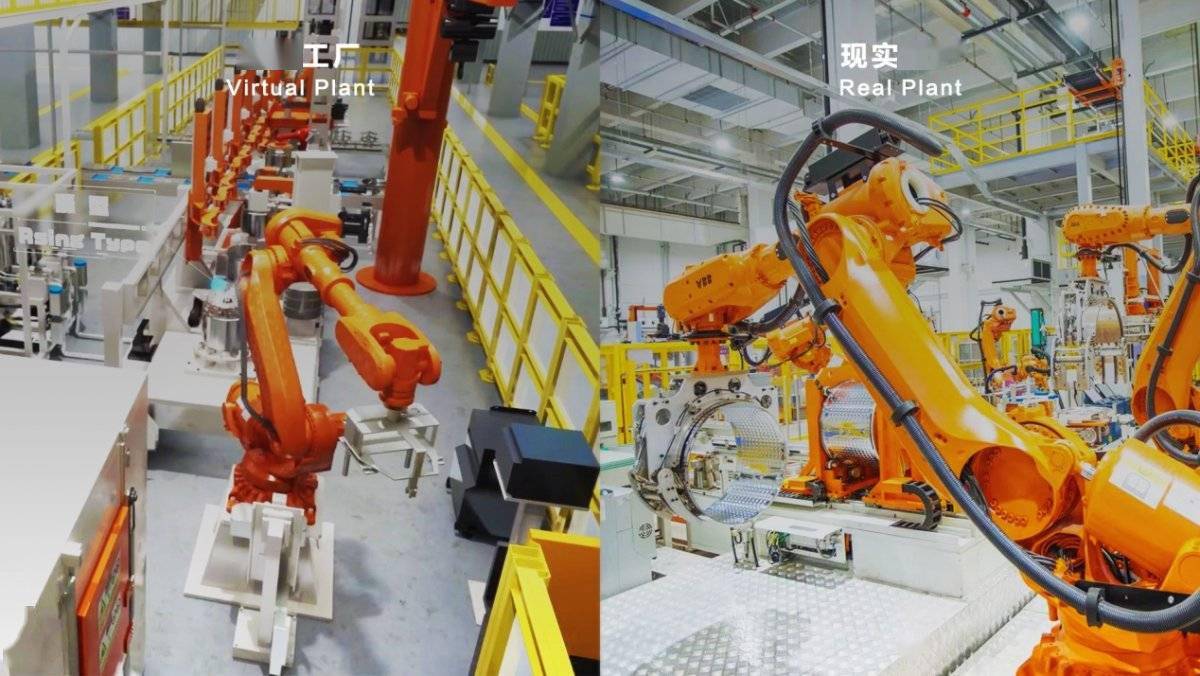

Today, the new technology and new experience gained from the more than ten-meter-long verification platform were used by COSMOPlat in Haier’s Shanghai washing machine interconnection factory. Here, a "virtual factory" based on digital twin technology works day and night, replacing the physical factory in completing "dress rehearsals" in planning, production operations, and debugging optimization, and analyzing and making decisions in countless "parallel universes." While outputting the "best answer" in reality, it also makes the visual, highly reliable, and easy-to-operate "industrial metaverse" come into reality.

Use the virtual to reflect the real to create the infrastructure of the "metaverse"

"Similar to reality, in order to set up the 'Metaverse', it first needs to build its infrastructure." As Ding Zhaozeng, manager of Haier Kaos Industrial Intelligence Solutions, said, during the factory construction stage, Kaos COSMOPlat used D3OS The digital twin solution completes the “infrastructure” construction of the metaverse for the factory.

By creating a 1:1 digital model that is completely consistent with the equipment and production line entities in the factory, planners can "build a factory" in the virtual environment through drag-and-drop and code-free methods, build production line models and schedule processes. Cloth simulation. In the traditional model, the skeleton welding line of the washing machine factory is usually located on the side of the inner drum line of the washing machine. However, through layout simulation, the factory innovatively places the skeleton welding line next to the inner and outer drum pre-assembly line, which not only prevents large items from falling to the ground, but also There have also been qualitative improvements in terms of storage area and logistics frequency.

Nowadays, this virtual factory that “reflects reality with virtual reality” can complete the real-time collection and cross-space presentation of all production lines and equipment in the factory. The original “black boxes” in the actual production process have also been opened. In order to ensure the accuracy of the equipment, the inner barrel of the washing machine adopts laser welding technology, so that the equipment is completely closed during operation and the production process is invisible. Digital twins can restore the daily operating actions of equipment in real time, monitor operating status and record relevant data.

And this digital world not only connects machinery and equipment. For the "new industrial workers" working in this "Yuanverse Factory", the new model of full-scenario interactive twin training runs through the open space of the entire factory, allowing them to receive on-the-job training and improve their digital skills, while also Experience free roaming in the new world of the "Industrial Metaverse". Even consumers have the opportunity to personalize their favorite products through the link between the "Industrial Metaverse" and the "Consumer Metaverse" and view their production processes in real time on the online platform.

Explore the value of industrial data by optimizing virtuality and reality

In addition to the immersion and visualization recognized by the industry and well-known by the public, as the informatization and digitization of factory scenes become increasingly in-depth, based on technologies such as data space and artificial intelligence, COSMOPlat is also creating an open interactive and data The digital world retained in real time achieves the transcendence of real physical space and time, allowing the data generated in the real world to be truly managed and used in the "industrial metaverse".

In the spatial dimension, external managers and designers can achieve spatial and immersive collaborative communication in the twin world of the factory. Global visibility of supplier quality and logistics data will also allow all defective products and Materials have nowhere to hide, breaking the spatial barriers and data barriers within enterprises and between enterprises in the industrial chain.

In the time dimension, due to the circulation and application of data, the "Industrial Metaverse" can even break the limitations of a single time stream. For example, through one code for one object and one file for each machine, the factory can check the production process of each product or component and the operating status of each equipment at any time, realizing full-cycle availability of complete products, parts, production equipment, logistics equipment, etc. Traceability, data is 100% traceable. At the same time, in the virtual production line, the factory also uses short-term and rapid simulation to verify the rationality of the production schedule in advance before actual production, predict possible production problems, and avoid or solve them in advance.

From factory construction to production, all inefficiencies and failures are left in the "trial and error" of the digital space. The factory does not have to experience any unnecessary risks and waste of resources, and can even restore the real world at 1:1 In the digital space, make some attempts that cannot or are inconvenient to do in the real world, provide the soil for new technologies and new models to enter industrial applications, and truly realize "what you get exceeds what you see."

Capacity Upgrading "Manufacturing" High-end Smart Factory

Casarte washing machines have achieved an absolute leading position in the washing machine market with a price of more than 10,000 yuan, and are recognized as high-end brands. If the Haier Shanghai washing machine factory as its production base allows us to see the ability of Chinese companies to manufacture high-end smart products, then COSMOPlat in Kaos shows us the ability of China's industrial Internet platform to "manufacture" high-end smart factories, as well as the formation of This ability requires a new way of thinking.

At a time when it is difficult for consumer-grade VR/AR devices to achieve a balance in performance, design, cost, etc., the "industrial metaverse" created by digital twins, artificial intelligence, big data, virtual reality and other technology integration scenarios seems to have It has become the closest place to the "Metaverse". At present, the Kaos D³OS digital twin solution has been applied in high-end equipment, auto parts, mining, rail transit and other industries, and has been empowered in the research and development of the first domestic snow wax car, Sanxingdui smart archaeology and other fields. It has not only expanded The application extension of digital technology also provides enterprises and users with a transformative experience of "virtual manufacturing reality, intelligent decision-making and production".

Regarding the future development plan of the "Industrial Metaverse", Haier Kaos Industrial Intelligence Solution Manager Ding Zhaozeng said, "We will strengthen our understanding of the 'Industrial Metaverse' and insist on using an open ecology to give full play to our virtual capabilities." We will explore and practice our advantages in production, simulation optimization and other aspects with industry-leading companies and service providers to help more companies realize their vision of digital transformation."

Digital twin technology originated from the aerospace industry and now helps people re-understand and manage industrial physical manufacturing. The development of digitalization will not only have a positive impact on entities, but will also bring about a series of new business applications and social progress. Kaos COSMOPlat will also accelerate the digital transformation of enterprises and the cultivation of key technologies and solutions for the "Industrial Metaverse", helping more enterprises explore and discover the value of data and move towards high-quality and sustainable development.

The above is the detailed content of Digital rehearsal, virtual factory construction! This top washing machine factory opens the door to the 'industrial metaverse'. For more information, please follow other related articles on the PHP Chinese website!

Hot AI Tools

Undresser.AI Undress

AI-powered app for creating realistic nude photos

AI Clothes Remover

Online AI tool for removing clothes from photos.

Undress AI Tool

Undress images for free

Clothoff.io

AI clothes remover

Video Face Swap

Swap faces in any video effortlessly with our completely free AI face swap tool!

Hot Article

Hot Tools

Notepad++7.3.1

Easy-to-use and free code editor

SublimeText3 Chinese version

Chinese version, very easy to use

Zend Studio 13.0.1

Powerful PHP integrated development environment

Dreamweaver CS6

Visual web development tools

SublimeText3 Mac version

God-level code editing software (SublimeText3)

Hot Topics

1387

1387

52

52

Top 5 GenAI Launches of February 2025: GPT-4.5, Grok-3 & More!

Mar 22, 2025 am 10:58 AM

Top 5 GenAI Launches of February 2025: GPT-4.5, Grok-3 & More!

Mar 22, 2025 am 10:58 AM

February 2025 has been yet another game-changing month for generative AI, bringing us some of the most anticipated model upgrades and groundbreaking new features. From xAI’s Grok 3 and Anthropic’s Claude 3.7 Sonnet, to OpenAI’s G

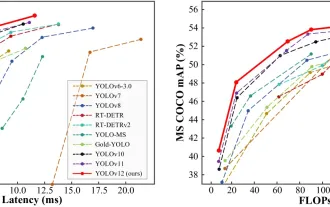

How to Use YOLO v12 for Object Detection?

Mar 22, 2025 am 11:07 AM

How to Use YOLO v12 for Object Detection?

Mar 22, 2025 am 11:07 AM

YOLO (You Only Look Once) has been a leading real-time object detection framework, with each iteration improving upon the previous versions. The latest version YOLO v12 introduces advancements that significantly enhance accuracy

Best AI Art Generators (Free & Paid) for Creative Projects

Apr 02, 2025 pm 06:10 PM

Best AI Art Generators (Free & Paid) for Creative Projects

Apr 02, 2025 pm 06:10 PM

The article reviews top AI art generators, discussing their features, suitability for creative projects, and value. It highlights Midjourney as the best value for professionals and recommends DALL-E 2 for high-quality, customizable art.

Is ChatGPT 4 O available?

Mar 28, 2025 pm 05:29 PM

Is ChatGPT 4 O available?

Mar 28, 2025 pm 05:29 PM

ChatGPT 4 is currently available and widely used, demonstrating significant improvements in understanding context and generating coherent responses compared to its predecessors like ChatGPT 3.5. Future developments may include more personalized interactions and real-time data processing capabilities, further enhancing its potential for various applications.

Best AI Chatbots Compared (ChatGPT, Gemini, Claude & More)

Apr 02, 2025 pm 06:09 PM

Best AI Chatbots Compared (ChatGPT, Gemini, Claude & More)

Apr 02, 2025 pm 06:09 PM

The article compares top AI chatbots like ChatGPT, Gemini, and Claude, focusing on their unique features, customization options, and performance in natural language processing and reliability.

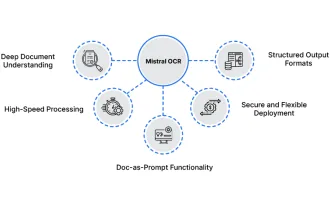

How to Use Mistral OCR for Your Next RAG Model

Mar 21, 2025 am 11:11 AM

How to Use Mistral OCR for Your Next RAG Model

Mar 21, 2025 am 11:11 AM

Mistral OCR: Revolutionizing Retrieval-Augmented Generation with Multimodal Document Understanding Retrieval-Augmented Generation (RAG) systems have significantly advanced AI capabilities, enabling access to vast data stores for more informed respons

Top AI Writing Assistants to Boost Your Content Creation

Apr 02, 2025 pm 06:11 PM

Top AI Writing Assistants to Boost Your Content Creation

Apr 02, 2025 pm 06:11 PM

The article discusses top AI writing assistants like Grammarly, Jasper, Copy.ai, Writesonic, and Rytr, focusing on their unique features for content creation. It argues that Jasper excels in SEO optimization, while AI tools help maintain tone consist

Getting Started With Meta Llama 3.2 - Analytics Vidhya

Apr 11, 2025 pm 12:04 PM

Getting Started With Meta Llama 3.2 - Analytics Vidhya

Apr 11, 2025 pm 12:04 PM

Meta's Llama 3.2: A Leap Forward in Multimodal and Mobile AI Meta recently unveiled Llama 3.2, a significant advancement in AI featuring powerful vision capabilities and lightweight text models optimized for mobile devices. Building on the success o