The shocking Tesla robot

Recently, Tesla humanoid robot appeared at the World Artificial Intelligence Conference, showing a new joint design structure.

Some analysts pointed out that Tesla is expected to use Chinese parts and components to create more cost-effective robots and replicate the advanced ecosystem of Apple's industrial chain.

▍Copy and Refactor

Apple has spent more than two decades and billions of dollars building an unprecedentedly complex supply chain model in China, helping iPhone reach 1.2 billion users worldwide and shipments of 226 million units in 2022.

Today, Tesla’s humanoid robot is a new product across the ages. With the help of huge market order expectations, it is also trying to reshape a new manufacturing system for humanoid robots in China and build a supply chain based on “Tesla standards” of miracles.

Comparing the practices of the two companies, we will be surprised to find that an excellent product is often difficult to obtain by adding, subtracting, or modifying parts already on the market. Forward design and industrial chain collaboration are the basic elements for the further improvement of corporate products and comprehensive strength.

In 1998, Cook took charge of Apple's computer production business. His approach was unique and difficult to understand, and had an important impact on the early development of Apple's supply chain.

At that time, Apple did not use off-the-shelf parts, but chose to customize a large number of products, which would significantly increase the cost.

But Apple insists on personally designing the manufacturing process of these parts and assembling these customized parts into extremely complex systems with unprecedented scale and flexibility.

This is obviously not easy. To this end, in the past fifteen years, Apple has used marketing to obtain larger orders to attract and reward suppliers. On the other hand, it has also gradually established an extremely complex, in-depth and high-cost supply and production system in China.

In order to ensure that this process is stable and controllable, Apple has been sending its top product designers and manufacturing design engineers to China to improve and polish the product manufacturing process.

After arriving in China, these Apple engineers will spend several months collaboratively designing a new production process and supervising the details of the production process until the production runs smoothly and operates normally. At the same time, they must also pay close attention to the supply. Whether the manufacturer's production complies with regulations.

Equipment is also part of Apple's investment. In addition to investing a lot of human resources, Apple has also spent billions of dollars to purchase customized equipment with suppliers and develop some exclusive expertise. For example, the aluminum alloy body integrated molding technology and the application technology of special welding wire materials shocked the world at the time.

Statistics show that with the increase in iPhone production in the early years, the value of Apple's "long-term assets (mainly used for manufacturing equipment)" in China soared from US$370 million in 2009 to US$7.3 billion in 2012.

At that time, this figure already exceeded the combined value of all Apple’s building assets and retail stores, a large part of which was the advanced CNC machine tools purchased by Apple.

Therefore, Apple’s standards and supply chain system have become the products of Apple’s entry into the global market and establishment of technological competitiveness, and have also profoundly affected Apple and China for many years to come.

In other words, Cook moved the production of Apple products from the United States to China, built an extremely efficient supply chain system in China, truly completed Jobs's design, and laid the foundation for Apple's rise.

Tesla is currently working hard to design a new humanoid robot that is unique on the market. Musk came to China to explore new industry chain restructuring opportunities among Chinese suppliers.

From conception to modeling to processing into a working robot, the Tesla robotics team not only integrates advanced car-making concepts into robot manufacturing, reshapes mechanical art with intelligent and efficient R&D speed, but also attempts to In the selection and procurement of parts, we began to establish our own standards.

The selection of parts and suppliers is not as easy as imagined. Apple initially used a "first principles" drill-down approach to find suppliers.

At that time, Apple would inquire and negotiate with suppliers for several hours, and then let engineers and suppliers commit to determine the number of customized parts required for mass production of Apple, but the condition is that must be effective Master the supplier's technology research and development roadmap, and at the same time gain a comprehensive understanding of any problems that may arise in various aspects such as cost, design and mass production.

But if cooperation is confirmed, Apple will help suppliers jointly improve and upgrade production lines. This is equivalent to putting the equipment it bought in other people's factories. This move also made Apple favored by more suppliers.

By insisting on following this strict supply chain screening and training process, Apple has grown with its suppliers for about ten years before establishing its current mature industrial chain system.

▍The power of systemization

Prior to this, close cooperation with Apple had brought huge benefits to suppliers, which also made suppliers willing to follow Apple's instructions and suggestions.

For example, Foxconn’s revenue in 2000 was approximately US$3 billion. In 2010, Foxconn’s revenue reached US$98 billion, exceeding the combined revenue of its five largest competitors. By 2022, Foxconn's revenue will reach US$214.2 billion.

With the strengthened bargaining power and voice driven by orders, the control of the details of parts allows Apple's supply chain to maintain efficient operation.

While other manufacturers are still busy negotiating specifications with suppliers, Apple engineers are already very good at asking more detailed inquiries about suppliers' standard specifications. They believe that when they ask enough questions, they will quickly discover the crux of the problem and solve the problem quickly.

This also allows Apple engineers to quickly move from the whole to the details, and then improve the whole from the details, ultimately pushing suppliers to passively accept improvements in small details.

In addition to equipment, Apple also controls resource circulation to the extreme.

Since 2008, at least 23.6 million workers have moved in Apple’s supply chain, a very high turnover rate. Suppliers focus on Apple's needs and form labor resources with a certain skill set and a certain form of production supporting combinations in surrounding cities and regions, and then refine them.

Finally, this industry chain has both subcontractors for various types of work and companies in various specialized fields.

This modular labor ratio can achieve a more flexible combination of productivity resources. It also allows Apple to quickly find corresponding resources after expanding production or improving processes, completing a highly developed manufacturing ecosystem. Build. Some analysts believe that Apple now only needs 14,000 people to supervise and control the weekly work of 1.5 million workers in the global supply chain. This is a systematic force.

The increase in inventory turnover rate reflects the huge systematic advantage. Apple's electronic products always stand out. Apple's inventory turnover rate is 2.5 times that of Nokia, and 12 times that of Coca-Cola, from a data perspective.

There are therefore concerns that the complex costs and production processes of humanoid robots may make it difficult to achieve high inventory turnover rates. How to solve this problem may require Tesla's longer-term investment in system construction before it is expected to move towards the 10 billion robots mentioned by Musk.

▍Tesla’s forward design

The good news is that Tesla is now screening and helping its own suppliers, and has begun preliminary comparison and testing of supplied supplier samples.

The difference is that Thanks to advanced technologies such as virtual simulation and 3D printing, Tesla has adopted a barbell-style vertical development process from R&D to production. That is to say, we pay attention to prototype design and virtual simulation testing at both ends. This allows Tesla to devote more energy to product improvement and parameter optimization in the early stages of design, rather than the intermediate manufacturing process.

For example, when studying the actuator of the Tesla robot Optimus, Tesla is trying a drive system with a

For example, when studying the actuator of the Tesla robot Optimus, Tesla is trying a drive system with a

, thereby completing the redesign and reconstruction of every detailed component. According to the judgment of some agencies, the Tesla humanoid robot Optimus unveiled this time is equipped with 12 motors each for the arms, palms, and legs, and 2 motors each for the neck and torso, a total of 40 motors, all of which use similar brand-new components and The structural design method forms two main forms: rotary actuator and linear actuator.

It needs to contain at least 3 series of motors, planetary roller screw actuators, and 3 series of motors, harmonic rotary actuators. Of course, we don’t rule out more new parts that we don’t know about yet.

As the marginal changes in Tesla's

industrial chain become more and more obvious, Tesla's new component production and combination methods have led to new developments such as planetary roller screws, coreless motors, The market for brand new components such as needle roller bearing products. Because parts such as the fingers of humanoid robots have a small space, the finger joints of humanoid robots will inevitably need to be equipped with more miniaturized motors that can output greater force in the future. At present, similar new coreless motors can indeed more perfectly meet the needs of humanoid robots for lightweight and high-precision finger joints.

Although the advantage of this part of the product is that it can self-lock & provide greater thrust, the difficulty lies in its small size and difficulty in processing the nut. The overall demand in the original market is low, so most of them require customized development and production. .

Under Tesla’s high expectations for the market, parts companies are currently scrambling to try to reach cooperation with Tesla. The agency pointed out that assuming that Tesla robots reach one million units, the cost of a single robot is expected to reach 190,000 yuan, of which the coreless cup motor module of a single robot is worth about 7,200 yuan, which may also make suppliers Willing to try to make customized molds for Tesla . Thanks to the news that Tesla is looking for Chinese suppliers to compare, the stock prices of companies such as MOONS Electric and Jiangsu Leili have risen sharply in the secondary market. It was revealed that relevant samples had been sent to Tesla in the United States and the test results were good and received high recognition. Southern Seiko once became a star target.

The market's hype logic is also very simple. On the one hand, the application field of coreless cups is relatively high-end, with high design and manufacturing barriers. We are optimistic about the application of humanoid robots in driving the market size of coreless cup motors. On the other hand,

Tesla Suppliers are also expected to replicate the growth trajectory of Apple’s original supplier cooperation, which is worth investing in.After receiving initial support from suppliers, Tesla used modular independent design to quickly form several sets of overall development plans with the help of parts, and then asked suppliers to process them according to this set of plans and indicators.

Then  Tesla engineers will put this plan into the virtual simulation software

Tesla engineers will put this plan into the virtual simulation software

to get the final result Dynamic parameters suitable for robot motion, and based on the actual situation, determine the problems of parts in certain actions, optimize the structure and packaging of modular actuators, and complete a forward design cycle . Thanks to the complete system design from scratch, engineers can optimize the product in depth and detail according to the design requirements, and ultimately deliver and iterate the design results quickly.

This vertical design process from 0-1 allows Tesla engineers to go deep into the design of electromagnetics and gear sets, and complete a very simple and compact packaging design, allowing the final robot's size and movement capabilities to reach a The ideal state alsosignificantly reduces the workload of the final system integration

.

▍Conclusion and the future

▍Conclusion and the future

Tesla’s humanoid robot production is currently in the early stages of supply chain cooperation, and the supplier list has not yet been announced. But if Tesla's original design plan is followed, a humanoid robot may eventually need more than 200 degrees of freedom, of which the hands alone have 27 degrees of freedom. At the same time, the power consumption of fast walking is only 500W, which will inevitably require a very huge supply chain support.

When the leading suppliers appear, it will not be easy for latecomers to imitate and surpass the technical moat brought by this supply chain.  For example, when the demand for mobile phones in China exploded, in order to keep up with Apple, global mobile phone manufacturers came to China one after another and began to seek help from suppliers, and ultimately

For example, when the demand for mobile phones in China exploded, in order to keep up with Apple, global mobile phone manufacturers came to China one after another and began to seek help from suppliers, and ultimately

, thus narrowing the gap with Apple. Apple’s series of supply chain system construction actions have helped Chinese suppliers obtain more orders. This order of magnitude advantage has reshaped the global mobile phone industry, has also enabled suppliers to improve their knowledge of cutting-edge manufacturing. understand. Of course, Apple has also successfully occupied the throne of the global electronic technology field through this supply chain cooperation.

For Apple, it is already very difficult to give up this supply chain system. Because even if it builds factories outside of China, the factory's subcontractors and suppliers are still from mainland China. Apple and China are largely tied to in-depth industrial cooperation. Nowadays, robots, as a brand-new product form, have become the focus of technological and industrial development. Our country's installed capacity of industrial robots has exceeded 50% of the global total, ranking first in the world for nine consecutive years. At the same time, it once again has a complete industrial chain that attracts global attention.

At present, domestic hardware suppliers already have strong low-cost large-scale mass production capabilities, and are most likely to be the first to introduce Tesla robot supply chain and seize industry opportunities.

It may not be surprising at all if Musk ultimately chooses Chinese suppliers for his robot components.

The above is the detailed content of The shocking Tesla robot. For more information, please follow other related articles on the PHP Chinese website!

Hot AI Tools

Undresser.AI Undress

AI-powered app for creating realistic nude photos

AI Clothes Remover

Online AI tool for removing clothes from photos.

Undress AI Tool

Undress images for free

Clothoff.io

AI clothes remover

Video Face Swap

Swap faces in any video effortlessly with our completely free AI face swap tool!

Hot Article

Hot Tools

Notepad++7.3.1

Easy-to-use and free code editor

SublimeText3 Chinese version

Chinese version, very easy to use

Zend Studio 13.0.1

Powerful PHP integrated development environment

Dreamweaver CS6

Visual web development tools

SublimeText3 Mac version

God-level code editing software (SublimeText3)

Hot Topics

1386

1386

52

52

How can AI make robots more autonomous and adaptable?

Jun 03, 2024 pm 07:18 PM

How can AI make robots more autonomous and adaptable?

Jun 03, 2024 pm 07:18 PM

In the field of industrial automation technology, there are two recent hot spots that are difficult to ignore: artificial intelligence (AI) and Nvidia. Don’t change the meaning of the original content, fine-tune the content, rewrite the content, don’t continue: “Not only that, the two are closely related, because Nvidia is expanding beyond just its original graphics processing units (GPUs). The technology extends to the field of digital twins and is closely connected to emerging AI technologies. "Recently, NVIDIA has reached cooperation with many industrial companies, including leading industrial automation companies such as Aveva, Rockwell Automation, Siemens and Schneider Electric, as well as Teradyne Robotics and its MiR and Universal Robots companies. Recently,Nvidiahascoll

After 2 months, the humanoid robot Walker S can fold clothes

Apr 03, 2024 am 08:01 AM

After 2 months, the humanoid robot Walker S can fold clothes

Apr 03, 2024 am 08:01 AM

Editor of Machine Power Report: Wu Xin The domestic version of the humanoid robot + large model team completed the operation task of complex flexible materials such as folding clothes for the first time. With the unveiling of Figure01, which integrates OpenAI's multi-modal large model, the related progress of domestic peers has been attracting attention. Just yesterday, UBTECH, China's "number one humanoid robot stock", released the first demo of the humanoid robot WalkerS that is deeply integrated with Baidu Wenxin's large model, showing some interesting new features. Now, WalkerS, blessed by Baidu Wenxin’s large model capabilities, looks like this. Like Figure01, WalkerS does not move around, but stands behind a desk to complete a series of tasks. It can follow human commands and fold clothes

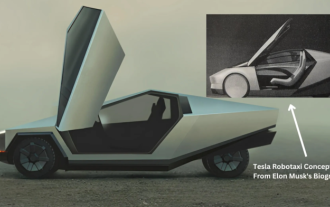

Tesla finally takes action! Will self-driving taxis be unveiled soon? !

Apr 08, 2024 pm 05:49 PM

Tesla finally takes action! Will self-driving taxis be unveiled soon? !

Apr 08, 2024 pm 05:49 PM

According to news on April 8, Tesla CEO Elon Musk recently revealed that Tesla is committed to developing self-driving car technology. The highly anticipated unmanned self-driving taxi Robotaxi will be launched on August 8. Official debut. The data editor learned that Musk's statement on Previously, Reuters reported that Tesla’s plan to drive cars would focus on the production of Robotaxi. However, Musk refuted this, accusing Reuters of having canceled plans to develop low-cost cars and once again publishing false reports, while making it clear that low-cost cars Model 2 and Robotax

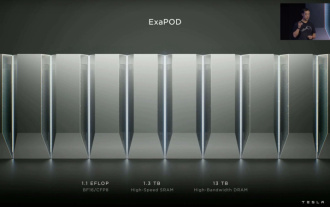

Tesla Dojo supercomputing debut, Musk: The computing power of AI training by the end of the year will be approximately equal to 8,000 NVIDIA H100 GPUs

Jul 24, 2024 am 10:38 AM

Tesla Dojo supercomputing debut, Musk: The computing power of AI training by the end of the year will be approximately equal to 8,000 NVIDIA H100 GPUs

Jul 24, 2024 am 10:38 AM

According to news from this website on July 24, Tesla CEO Elon Musk (Elon Musk) stated in today’s earnings conference call that the company is about to complete the largest artificial intelligence training cluster to date, which will be equipped with 2 Thousands of NVIDIA H100 GPUs. Musk also told investors on the company's earnings call that Tesla would work on developing its Dojo supercomputer because GPUs from Nvidia are expensive. This site translated part of Musk's speech as follows: The road to competing with NVIDIA through Dojo is difficult, but I think we have no choice. We are now over-reliant on NVIDIA. From NVIDIA's perspective, they will inevitably increase the price of GPUs to a level that the market can bear, but

Ten humanoid robots shaping the future

Mar 22, 2024 pm 08:51 PM

Ten humanoid robots shaping the future

Mar 22, 2024 pm 08:51 PM

The following 10 humanoid robots are shaping our future: 1. ASIMO: Developed by Honda, ASIMO is one of the most well-known humanoid robots. Standing 4 feet tall and weighing 119 pounds, ASIMO is equipped with advanced sensors and artificial intelligence capabilities that allow it to navigate complex environments and interact with humans. ASIMO's versatility makes it suitable for a variety of tasks, from assisting people with disabilities to delivering presentations at events. 2. Pepper: Created by Softbank Robotics, Pepper aims to be a social companion for humans. With its expressive face and ability to recognize emotions, Pepper can participate in conversations, help in retail settings, and even provide educational support. Pepper's

Cloud Whale Xiaoyao 001 sweeping and mopping robot has a 'brain'! | Experience

Apr 26, 2024 pm 04:22 PM

Cloud Whale Xiaoyao 001 sweeping and mopping robot has a 'brain'! | Experience

Apr 26, 2024 pm 04:22 PM

Sweeping and mopping robots are one of the most popular smart home appliances among consumers in recent years. The convenience of operation it brings, or even the need for no operation, allows lazy people to free their hands, allowing consumers to "liberate" from daily housework and spend more time on the things they like. Improved quality of life in disguised form. Riding on this craze, almost all home appliance brands on the market are making their own sweeping and mopping robots, making the entire sweeping and mopping robot market very lively. However, the rapid expansion of the market will inevitably bring about a hidden danger: many manufacturers will use the tactics of sea of machines to quickly occupy more market share, resulting in many new products without any upgrade points. It is also said that they are "matryoshka" models. Not an exaggeration. However, not all sweeping and mopping robots are

Real-life version of WALL-E, Disney demonstrates new bipedal robot: able to navigate complex terrain such as slopes/steps

Jul 20, 2024 pm 06:31 PM

Real-life version of WALL-E, Disney demonstrates new bipedal robot: able to navigate complex terrain such as slopes/steps

Jul 20, 2024 pm 06:31 PM

This website reported on July 20 that the Disney research team designed and produced a new bipedal robot that can traverse unstructured terrain such as slopes and steps in the theme park. Note on this site: The video source is Disney, uploaded to Station B by Turkey Brothers. Disney hopes that through this bipedal robot project, it combines procedural animation, modular hardware and reinforcement learning to design and program a robot that can make these unique gaits and movements. Characteristic walking character. This bipedal robot is somewhat similar to Wall-E, the protagonist in the 2008 movie "Wall-E," except that it has a flat head and a boxy body. Image source: WikiMedia Disney stated that the design focus of the project is on character-driven mechanical properties, proposing a control architecture based on reinforcement learning to perform robustly

Supports Chinese dialogue! New NVIDIA ChatRTX updated

Jun 09, 2024 am 11:25 AM

Supports Chinese dialogue! New NVIDIA ChatRTX updated

Jun 09, 2024 am 11:25 AM

As early as February, NVIDIA launched the LLM-based chatbot ChatwithRTX. In May, the chatbot was updated, adding new models and new functions, the packaging package was also reduced from 35G to 11G, and the software was officially renamed ChatRTX. In the previous article and video about ChatwithRTX, we mentioned that ChatwithRTX does not have its own Chinese reply. If you want to implement Chinese answers, you need to install your own environment, large language models, etc. But this step has a relatively high threshold for users, and they have to go through many complicated steps to achieve Chinese question and answer. Before the introduction, let’s briefly talk about what ChatRTX is.