Technology peripherals

Technology peripherals

AI

AI

Songjiang Robot Company: Make the super-large central kitchen smarter and extend the working range to 3 meters!

Songjiang Robot Company: Make the super-large central kitchen smarter and extend the working range to 3 meters!

Songjiang Robot Company: Make the super-large central kitchen smarter and extend the working range to 3 meters!

Comau (Shanghai) Engineering Co., Ltd. provided automation solutions for the Chengdu Tianfu Smart Kitchen Project to reduce labor costs and improve space utilization, thereby improving the efficiency of warehousing logistics operations and management

As the most intelligent super-large central kitchen project in the country, the Chengdu Tianfu Smart Kitchen Project has a total annual production capacity of 300,000 tons. At present, the central kitchen has developed to a stage in which rough processing links such as cleaning, mixing, and chopping have been fully automated. However, the two key links of warehousing, packaging and terminal transportation still mainly rely on manual operations

In order to achieve the highest standards of food safety and end-of-line automation solutions, Tianfu Smart Kitchen has chosen Comau as its partner. Comau cooperated with Xinglu Intelligent Packaging (Kunshan) Co., Ltd. (hereinafter referred to as "Xinglu Packaging"), a subsidiary of Xingpac Group, a robot integrator, to design and build a comprehensive robot automation solution including intelligent software and hardware for Tianfu Smart Kitchen, which was installed in The large kitchen production line end and semi-finished product temporary storage area improve operating efficiency for food packaging and terminal transportation

Comau and Xinglu Packaging cooperated to develop an octagonal square three-dimensional warehouse, which was deployed in the semi-finished product temporary storage area. The combination of this octagonal structure shelf and robot can maximize the use of space in a limited warehouse area, and also has the advantage of greater flexibility. Comau has deployed 7 high-speed palletizing robots at the end of the production line. Their working range can reach 3 meters and the operating rhythm can reach up to 2100 cycles/hour, thereby ensuring the meal delivery efficiency of Tianfu Smart Kitchen

Comau also optimized the robot program so that it can continuously adjust its trajectory and attitude. These optimizations include variable location sizes, how locations are moved, and automatic return to the nearest location, bringing greater flexibility to the entire warehouse management system. According to the design instructions, the robot can reach the designated warehouse location more quickly, thus improving the outbound capability

Source: Shanghai Songjiang District

The above is the detailed content of Songjiang Robot Company: Make the super-large central kitchen smarter and extend the working range to 3 meters!. For more information, please follow other related articles on the PHP Chinese website!

Hot AI Tools

Undresser.AI Undress

AI-powered app for creating realistic nude photos

AI Clothes Remover

Online AI tool for removing clothes from photos.

Undress AI Tool

Undress images for free

Clothoff.io

AI clothes remover

AI Hentai Generator

Generate AI Hentai for free.

Hot Article

Hot Tools

Notepad++7.3.1

Easy-to-use and free code editor

SublimeText3 Chinese version

Chinese version, very easy to use

Zend Studio 13.0.1

Powerful PHP integrated development environment

Dreamweaver CS6

Visual web development tools

SublimeText3 Mac version

God-level code editing software (SublimeText3)

Hot Topics

1386

1386

52

52

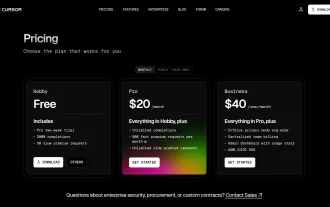

I Tried Vibe Coding with Cursor AI and It's Amazing!

Mar 20, 2025 pm 03:34 PM

I Tried Vibe Coding with Cursor AI and It's Amazing!

Mar 20, 2025 pm 03:34 PM

Vibe coding is reshaping the world of software development by letting us create applications using natural language instead of endless lines of code. Inspired by visionaries like Andrej Karpathy, this innovative approach lets dev

Top 5 GenAI Launches of February 2025: GPT-4.5, Grok-3 & More!

Mar 22, 2025 am 10:58 AM

Top 5 GenAI Launches of February 2025: GPT-4.5, Grok-3 & More!

Mar 22, 2025 am 10:58 AM

February 2025 has been yet another game-changing month for generative AI, bringing us some of the most anticipated model upgrades and groundbreaking new features. From xAI’s Grok 3 and Anthropic’s Claude 3.7 Sonnet, to OpenAI’s G

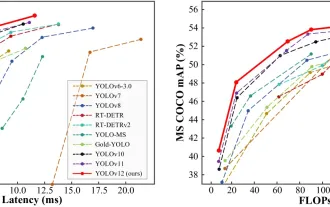

How to Use YOLO v12 for Object Detection?

Mar 22, 2025 am 11:07 AM

How to Use YOLO v12 for Object Detection?

Mar 22, 2025 am 11:07 AM

YOLO (You Only Look Once) has been a leading real-time object detection framework, with each iteration improving upon the previous versions. The latest version YOLO v12 introduces advancements that significantly enhance accuracy

Best AI Art Generators (Free & Paid) for Creative Projects

Apr 02, 2025 pm 06:10 PM

Best AI Art Generators (Free & Paid) for Creative Projects

Apr 02, 2025 pm 06:10 PM

The article reviews top AI art generators, discussing their features, suitability for creative projects, and value. It highlights Midjourney as the best value for professionals and recommends DALL-E 2 for high-quality, customizable art.

Is ChatGPT 4 O available?

Mar 28, 2025 pm 05:29 PM

Is ChatGPT 4 O available?

Mar 28, 2025 pm 05:29 PM

ChatGPT 4 is currently available and widely used, demonstrating significant improvements in understanding context and generating coherent responses compared to its predecessors like ChatGPT 3.5. Future developments may include more personalized interactions and real-time data processing capabilities, further enhancing its potential for various applications.

Best AI Chatbots Compared (ChatGPT, Gemini, Claude & More)

Apr 02, 2025 pm 06:09 PM

Best AI Chatbots Compared (ChatGPT, Gemini, Claude & More)

Apr 02, 2025 pm 06:09 PM

The article compares top AI chatbots like ChatGPT, Gemini, and Claude, focusing on their unique features, customization options, and performance in natural language processing and reliability.

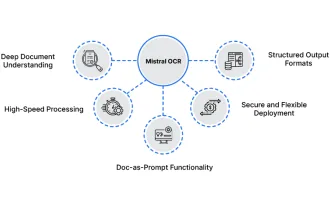

How to Use Mistral OCR for Your Next RAG Model

Mar 21, 2025 am 11:11 AM

How to Use Mistral OCR for Your Next RAG Model

Mar 21, 2025 am 11:11 AM

Mistral OCR: Revolutionizing Retrieval-Augmented Generation with Multimodal Document Understanding Retrieval-Augmented Generation (RAG) systems have significantly advanced AI capabilities, enabling access to vast data stores for more informed respons

Top AI Writing Assistants to Boost Your Content Creation

Apr 02, 2025 pm 06:11 PM

Top AI Writing Assistants to Boost Your Content Creation

Apr 02, 2025 pm 06:11 PM

The article discusses top AI writing assistants like Grammarly, Jasper, Copy.ai, Writesonic, and Rytr, focusing on their unique features for content creation. It argues that Jasper excels in SEO optimization, while AI tools help maintain tone consist