Technology peripherals

Technology peripherals

AI

AI

Peng Shui: Drone infrared temperature measurement helps power grid inspection fly

Peng Shui: Drone infrared temperature measurement helps power grid inspection fly

Peng Shui: Drone infrared temperature measurement helps power grid inspection fly

On August 17, under the scorching sun, the staff of the transmission and inspection team of State Grid Pengshui Power Supply Company came to the No. 1 main transformer of the 220 kV Pengshui Station to conduct drone infrared temperature measurement to ensure the safety and reliability of the power grid during the high temperatures in summer. .

It is reported that as the temperature continues to rise, the power load of Pengshui Power Grid continues to rise, and some high-voltage transmission lines are already under high load. In order to ensure the normal use of electricity for residents during the peak summer season, the transmission and transportation inspection team of State Grid Pengshui Power Supply Company used drones to conduct "physical inspections" of high-voltage transmission equipment.

Under Hu Guohong's skillful operation, the drone rose steadily to high altitude and shuttled through the substation according to the planned route in advance. Every time it reaches an inspection point, the drone will stop briefly and look at the equipment "seriously" with its lens. At the same moment, two images, visible light and infrared, are clearly displayed on the display screen. "It can be seen that the current temperature of the main transformer switch joint is 47.2 degrees Celsius, and the equipment is running well." Hu Guohong said.

Use drones to conduct "physical examinations" of high-voltage power transmission equipment. Photo by Liu Tingwei

Compared with ordinary infrared temperature measurement, drone infrared temperature measurement can reduce the labor intensity of manual temperature measurement. Especially in areas with complex terrain, there is no need to get close to power transmission equipment for inspection, saving time and energy. The transmission operation and maintenance staff can judge and analyze the temperature measurement data through the data images transmitted back by the drone, and promptly detect line defects

State Grid Pengshui Power Supply Company also organized personnel to conduct "reviews" of lines that have had problems in the past, record and organize temperature measurement data in detail, record and compare temperature measurement data, and comprehensively consider defect management effect, ensuring the maximum inspection effect and ensuring the stable operation of line equipment in high-temperature weather.

Since the peak of summer, the transmission and inspection team of State Grid Pengshui Power Supply Company has used drones to complete 4 800 kV transmission lines, 8 500 kV transmission lines, 14 220 kV transmission lines, 6 Infrared temperature measurement of 110 kV transmission lines, 8 35 kV transmission lines, and 17 substations, and timely elimination of safety hazards. In the next step, by further increasing the number of patrols and using technologies such as infrared temperature measurement and live detection, we will measure the temperature of main transformers and lines in key substations every day, so as to grasp the real operating status of the equipment in real time, eliminate hidden dangers and defects in a timely manner, and conduct inspections on heavy-duty equipment. We will carry out load transfer and adjustment on the power grid and lines, and make every effort to protect the safety of Pengshui power grid and ensure that the people of the county have a cool summer. (Cai Guangjin, Liu Tingwei)

The above is the detailed content of Peng Shui: Drone infrared temperature measurement helps power grid inspection fly. For more information, please follow other related articles on the PHP Chinese website!

Hot AI Tools

Undresser.AI Undress

AI-powered app for creating realistic nude photos

AI Clothes Remover

Online AI tool for removing clothes from photos.

Undress AI Tool

Undress images for free

Clothoff.io

AI clothes remover

AI Hentai Generator

Generate AI Hentai for free.

Hot Article

Hot Tools

Notepad++7.3.1

Easy-to-use and free code editor

SublimeText3 Chinese version

Chinese version, very easy to use

Zend Studio 13.0.1

Powerful PHP integrated development environment

Dreamweaver CS6

Visual web development tools

SublimeText3 Mac version

God-level code editing software (SublimeText3)

Hot Topics

1377

1377

52

52

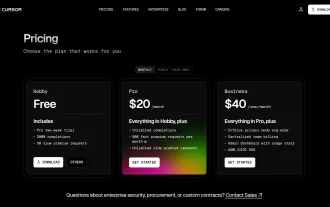

I Tried Vibe Coding with Cursor AI and It's Amazing!

Mar 20, 2025 pm 03:34 PM

I Tried Vibe Coding with Cursor AI and It's Amazing!

Mar 20, 2025 pm 03:34 PM

Vibe coding is reshaping the world of software development by letting us create applications using natural language instead of endless lines of code. Inspired by visionaries like Andrej Karpathy, this innovative approach lets dev

Top 5 GenAI Launches of February 2025: GPT-4.5, Grok-3 & More!

Mar 22, 2025 am 10:58 AM

Top 5 GenAI Launches of February 2025: GPT-4.5, Grok-3 & More!

Mar 22, 2025 am 10:58 AM

February 2025 has been yet another game-changing month for generative AI, bringing us some of the most anticipated model upgrades and groundbreaking new features. From xAI’s Grok 3 and Anthropic’s Claude 3.7 Sonnet, to OpenAI’s G

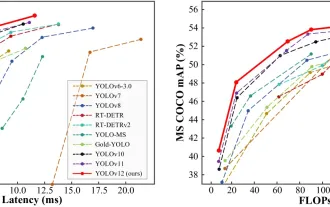

How to Use YOLO v12 for Object Detection?

Mar 22, 2025 am 11:07 AM

How to Use YOLO v12 for Object Detection?

Mar 22, 2025 am 11:07 AM

YOLO (You Only Look Once) has been a leading real-time object detection framework, with each iteration improving upon the previous versions. The latest version YOLO v12 introduces advancements that significantly enhance accuracy

Is ChatGPT 4 O available?

Mar 28, 2025 pm 05:29 PM

Is ChatGPT 4 O available?

Mar 28, 2025 pm 05:29 PM

ChatGPT 4 is currently available and widely used, demonstrating significant improvements in understanding context and generating coherent responses compared to its predecessors like ChatGPT 3.5. Future developments may include more personalized interactions and real-time data processing capabilities, further enhancing its potential for various applications.

Google's GenCast: Weather Forecasting With GenCast Mini Demo

Mar 16, 2025 pm 01:46 PM

Google's GenCast: Weather Forecasting With GenCast Mini Demo

Mar 16, 2025 pm 01:46 PM

Google DeepMind's GenCast: A Revolutionary AI for Weather Forecasting Weather forecasting has undergone a dramatic transformation, moving from rudimentary observations to sophisticated AI-powered predictions. Google DeepMind's GenCast, a groundbreak

Best AI Art Generators (Free & Paid) for Creative Projects

Apr 02, 2025 pm 06:10 PM

Best AI Art Generators (Free & Paid) for Creative Projects

Apr 02, 2025 pm 06:10 PM

The article reviews top AI art generators, discussing their features, suitability for creative projects, and value. It highlights Midjourney as the best value for professionals and recommends DALL-E 2 for high-quality, customizable art.

Which AI is better than ChatGPT?

Mar 18, 2025 pm 06:05 PM

Which AI is better than ChatGPT?

Mar 18, 2025 pm 06:05 PM

The article discusses AI models surpassing ChatGPT, like LaMDA, LLaMA, and Grok, highlighting their advantages in accuracy, understanding, and industry impact.(159 characters)

o1 vs GPT-4o: Is OpenAI's New Model Better Than GPT-4o?

Mar 16, 2025 am 11:47 AM

o1 vs GPT-4o: Is OpenAI's New Model Better Than GPT-4o?

Mar 16, 2025 am 11:47 AM

OpenAI's o1: A 12-Day Gift Spree Begins with Their Most Powerful Model Yet December's arrival brings a global slowdown, snowflakes in some parts of the world, but OpenAI is just getting started. Sam Altman and his team are launching a 12-day gift ex