Technology peripherals

Technology peripherals

It Industry

It Industry

Jiangsu Times Memory Wafer Factory fell into bankruptcy proceedings, and no one bought the lithography machine at the auction

Jiangsu Times Memory Wafer Factory fell into bankruptcy proceedings, and no one bought the lithography machine at the auction

Jiangsu Times Memory Wafer Factory fell into bankruptcy proceedings, and no one bought the lithography machine at the auction

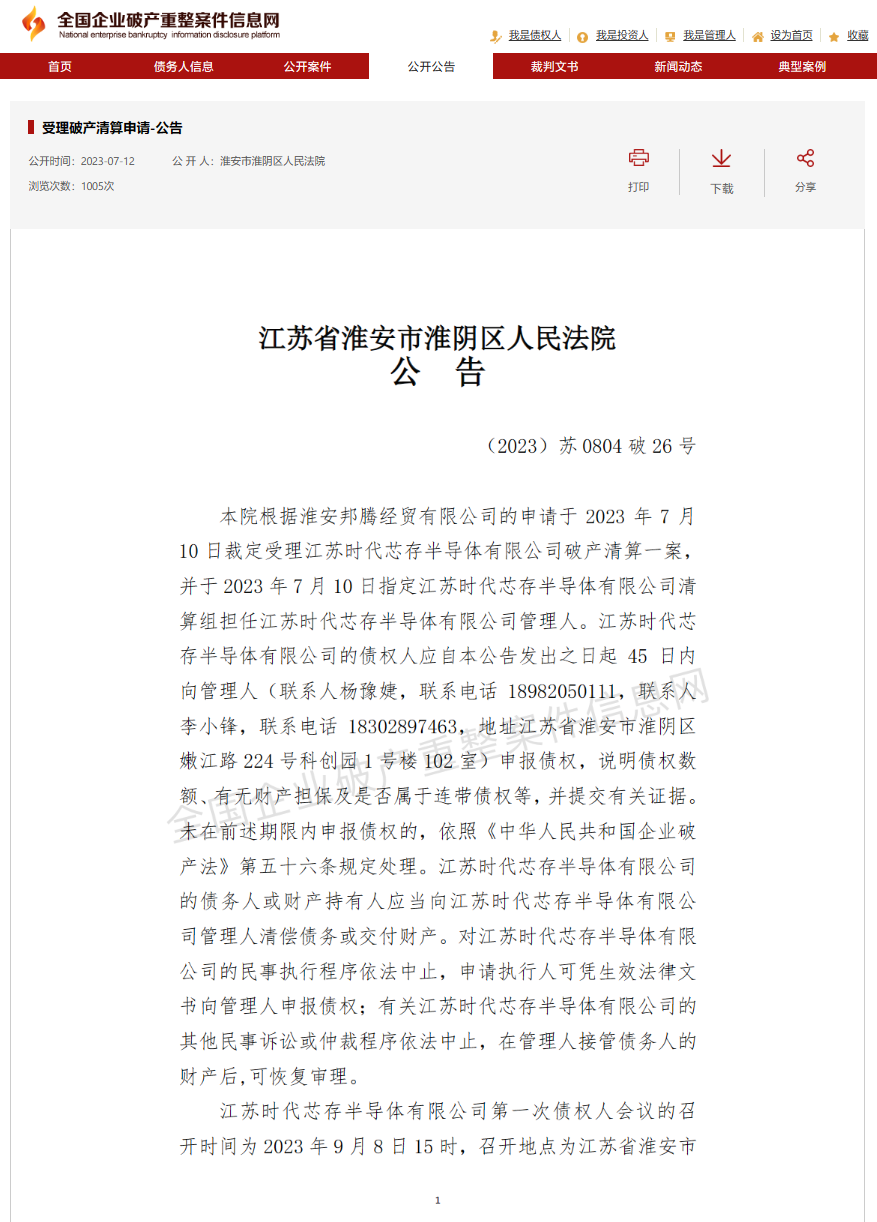

News from this site on August 28, According to public information from the National Enterprise Bankruptcy and Reorganization Case Information Network, Jiangsu Times Xincun Semiconductor Co., Ltd. has officially entered the bankruptcy liquidation procedure. This company has a total planned investment of 130 The 12-inch wafer fab worth RMB 100 million has previously stated that it is "determined to build an annual output of 100,000 pieces of phase change memory."

After inquiries, this site learned that The People's Court of Huaiyin District, Huai'an City, Jiangsu Province officially accepted the bankruptcy liquidation case of Jiangsu Times Xincun Semiconductor Co., Ltd. in July 2023, and ordered the company's ASML The lithography machine is undergoing a public auction. It is reported that the price of the second-hand ASML lithography machine purchased by Times Core is US$28.68 million (note on this site: currently about 209 million yuan).

However, according to the Taobao website of the People's Court of Huaiyin District, Huai'an City, Jiangsu Province According to public information on the judicial auction online platform, there is no potential buyer for this ASML lithography machine, and the auction information for this equipment has now been withdrawn.

According to data, Jiangsu Times AMS Semiconductor Co., Ltd. (AMS) settled in the national Huaian High-tech Industrial Development Zone in October 2016. The total investment in the project is 13 billion yuan. The company is a joint venture established by Beijing Times All-Chip Storage Technology Co., Ltd. and Huaian Yuanxing Investment Co., Ltd., aiming to develop and produce storage products equipped with the latest PCM technology

Since its first launch on March 22, 2018 Since moving in the first piece of equipment, the company has entered the production equipment debugging stage, and in August 2019 released the first 2-megabit electrically erasable programmable read-only phase change memory based on phase change materials

phase change Memory is a new generation memory product based on phase change materials, and it is also the most mature new generation storage technology recognized by the industry. In addition to its huge advantages in reading and writing speed, it also has unique advantages in stability, power consumption and radiation resistance. Therefore, it can be widely used in industrial control, automobiles, mechanical equipment, smart homes, 5G networks, consumer electronics and other fields, with huge market potential

Advertising statement: This article contains external jump links (including but not Not limited to hyperlinks, QR codes, passwords, etc.), intended to provide more information and save screening time, for reference only. Please note that all articles on this site contain this statement

The above is the detailed content of Jiangsu Times Memory Wafer Factory fell into bankruptcy proceedings, and no one bought the lithography machine at the auction. For more information, please follow other related articles on the PHP Chinese website!

Hot AI Tools

Undresser.AI Undress

AI-powered app for creating realistic nude photos

AI Clothes Remover

Online AI tool for removing clothes from photos.

Undress AI Tool

Undress images for free

Clothoff.io

AI clothes remover

Video Face Swap

Swap faces in any video effortlessly with our completely free AI face swap tool!

Hot Article

Hot Tools

Notepad++7.3.1

Easy-to-use and free code editor

SublimeText3 Chinese version

Chinese version, very easy to use

Zend Studio 13.0.1

Powerful PHP integrated development environment

Dreamweaver CS6

Visual web development tools

SublimeText3 Mac version

God-level code editing software (SublimeText3)

Hot Topics

1390

1390

52

52

ASML CEO promises to deliver the first High-NA EUV lithography machine by the end of the year: it is about the same size as a truck and costs $300 million each

Sep 18, 2023 pm 12:49 PM

ASML CEO promises to deliver the first High-NA EUV lithography machine by the end of the year: it is about the same size as a truck and costs $300 million each

Sep 18, 2023 pm 12:49 PM

According to news from this website on September 6, ASML CEO Peter Wennink recently stated in an interview with Reuters that despite some obstacles from suppliers, the company will still deliver HighNAEUV machines before the end of this year in accordance with the previously set plan. ASML said that a high-numerical aperture EUV lithography (High-NAEUV) equipment is about the same size as a truck. Each equipment sells for more than 300 million U.S. dollars (note on this site: currently about 2.19 billion yuan), which can meet the needs of first-line chip manufacturing. According to the needs of manufacturers, smaller and better chips can be manufactured in the next ten years. Wennink said some suppliers were unable to improve the quantity and quality of components, resulting in minor delays, but overall these difficulties can be overcome.

ASML responds to DUV lithography machine export approval issues: only some models are restricted

Jul 01, 2023 pm 05:33 PM

ASML responds to DUV lithography machine export approval issues: only some models are restricted

Jul 01, 2023 pm 05:33 PM

According to news on July 1, according to the editor's understanding, ASML, the leader of lithography machines, recently responded to questions about the export approval of its DUV lithography machines and further clarified relevant regulations and timetables. According to ASML’s statement, the export control regulations only apply to some of the latest models of DUV lithography machines, especially TWINSCANNXT:2000i and its subsequent immersion lithography systems. EUV lithography machines have been restricted before, and the shipment of other types of lithography machines has not been controlled. ASML emphasized that this control regulation will officially take effect on September 1, and the company has actively submitted license applications to relevant departments to ensure the normal conduct of business. Therefore, DUV lithography machines shipped before September 1 will not be affected.

ASML CFO Dassen responded to doubts: High-NA EUV lithography is still the most economical choice in the future, and related orders are steadily increasing

Feb 02, 2024 pm 05:00 PM

ASML CFO Dassen responded to doubts: High-NA EUV lithography is still the most economical choice in the future, and related orders are steadily increasing

Feb 02, 2024 pm 05:00 PM

According to news from this site on February 2, ASML Chief Financial Officer Roger Dassen recently accepted an interview with local Dutch media Bits&Chips. In the interview, Dassen responded to the doubts of the analysis agency SemiAnalysis, saying that High-NA (high numerical aperture) EUV (extreme ultraviolet light) lithography machines are still the most economical choice in the future. SemiAnalysis previously published an article arguing that High-NA lithography technology will use higher exposure doses, thereby significantly reducing wafer throughput per unit time. This means that compared to using the existing 0.33NA EUV lithography machine with multiple exposures, the introduction of High-NA will not bring cost advantages in the near future. Dassen recognizes

Who invented the lithography machine?

Oct 09, 2022 pm 02:04 PM

Who invented the lithography machine?

Oct 09, 2022 pm 02:04 PM

The lithography machine was invented by Frenchman Nicephore Niepce in 1822. At first, Nicephore Niepce discovered a mark that could be engraved on oil paper. When it appeared on the glass sheet, after a period of exposure, , the light-transparent part will become very hard, but the opaque part can be washed away with rosin and vegetable oil.

Samsung plans to invest 10 trillion won in semiconductor equipment and purchase ASML EUV lithography machines in large quantities

Nov 15, 2023 pm 12:33 PM

Samsung plans to invest 10 trillion won in semiconductor equipment and purchase ASML EUV lithography machines in large quantities

Nov 15, 2023 pm 12:33 PM

Samsung plans to increase the import of more ASML extreme ultraviolet (EUV) lithography equipment, according to a report from South Korea's Electronic News Today. Although the confidentiality clause in the contract did not disclose specific details, according to securities market news, this agreement will allow ASML to A total of 50 sets of equipment will be provided within five years. The unit price of each equipment is approximately 200 billion won (approximately 1.102 billion yuan), and the total value can reach 10 trillion won (approximately 55.1 billion yuan). It is currently unclear what the contract The product is an existing EUV lithography equipment or a next-generation "HighNAEUV" lithography equipment. However, the biggest problem with current EUV lithography equipment is limited output. According to officials, it is "more complex than satellite components" and can only be produced in very limited quantities each year. according to

TSMC's Kumamoto plant plans to start production in April 2024, and is expected to achieve large-scale mass production in Q4, reaching a monthly production capacity of 55,000 12-inch wafers.

Dec 18, 2023 pm 09:25 PM

TSMC's Kumamoto plant plans to start production in April 2024, and is expected to achieve large-scale mass production in Q4, reaching a monthly production capacity of 55,000 12-inch wafers.

Dec 18, 2023 pm 09:25 PM

The No. 1 factory in Kumamoto Prefecture under construction by TSMC is scheduled to hold an opening ceremony in late February next year, and is scheduled to enter the final stage of production preparations in the second quarter (April to June). According to Nikkei, TSMC’s Japanese subsidiary (JASM) President Yuichi Hota said that the construction of TSMC's factory in Kumamoto is progressing smoothly and is about to be completed. They plan to start equipment import and installation in October. It is expected that TSMC’s Kumamoto factory will be put into production in April 2024 and mass production will begin in the fourth quarter. The monthly production capacity will reach 55,000 12-inch wafers. When mentioning supply chain partners, he pointed out that in addition to TSMC’s existing suppliers , and 120 Japanese companies have joined the cooperation. Currently, Japanese companies account for approximately 25% of procurement in the supply chain.

It can reduce the use of expensive EUV lithography. Merck of Germany says DSA self-assembly technology will be commercially available within ten years.

Feb 05, 2024 pm 02:40 PM

It can reduce the use of expensive EUV lithography. Merck of Germany says DSA self-assembly technology will be commercially available within ten years.

Feb 05, 2024 pm 02:40 PM

According to news from this website on February 5, Anand Nambier, senior vice president of Merck of Germany, said at a press conference recently that DSA self-assembly technology will be commercialized in the next ten years, which can reduce the number of expensive EUV patterning and become an existing photolithography A great addition to the technology. Note from this site: DSA stands for Directedself-assembly, which uses the surface characteristics of block copolymers to realize the automatic construction of periodic patterns, and then induces them to eventually form the desired pattern with controllable direction. It is generally believed that DSA is not suitable for use as an independent patterning technology, but is combined with other patterning technologies (such as traditional photolithography) to produce high-precision semiconductors. ▲AnandNambier at the press conference. Picture source T

Foxconn builds AI one-stop service, and invested Sharp to enter advanced semiconductor packaging: put into production in 2026, designed to produce 20,000 wafers per month

Jul 18, 2024 pm 02:17 PM

Foxconn builds AI one-stop service, and invested Sharp to enter advanced semiconductor packaging: put into production in 2026, designed to produce 20,000 wafers per month

Jul 18, 2024 pm 02:17 PM

According to news from this site on July 11, the Economic Daily reported today (July 11) that Foxconn Group has entered the advanced packaging field, focusing on the current mainstream panel-level fan-out packaging (FOPLP) semiconductor solution. 1. Following its subsidiary Innolux, Sharp, invested by Foxconn Group, also announced its entry into Japan's panel-level fan-out packaging field and is expected to be put into production in 2026. Foxconn Group itself has sufficient influence in the AI field, and by making up for its shortcomings in advanced packaging, it can provide "one-stop" services to facilitate the acceptance of more AI product orders in the future. According to public information consulted on this site, Foxconn Group currently holds 10.5% of Sharp's shares. The group stated that it will not increase or reduce its holdings at this stage and will maintain its holdings.