Bosch’s official website shows that Bosch has begun producing new powertrain solutions based on 800V technology to increase charging speed. The new inverter uses silicon carbide (SiC) semiconductors for improved energy efficiency; the 800V motor version offers increased power density, a more compact design and reduced weight

This site noticed that the 800V inverter uses silicon carbide chips. Carbon atoms are introduced into the crystal structure of ultrapure silicon, improving the semiconductor's conductivity. In power electronics, energy loss in the form of heat is reduced by approximately 50%.

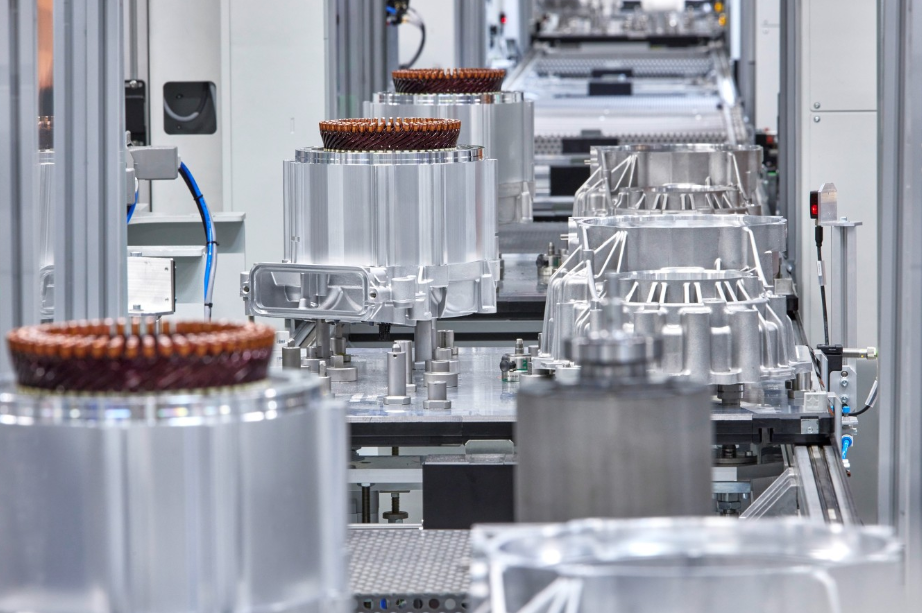

The 800V version of the Bosch motor, now in mass production, is characterized by 830N·m torque and 460kW output power. Thanks to the I-type needle bar winding, the efficiency, compactness and production automation level of the motor can be further improved.

The power density of the 800V version of the motor is increased by 35%, reaching 60 kW per liter, while providing a torque density of 105N·m per kilogram, which means that the maximum efficiency of the motor reaches 98%

Advertising Statement: This article contains external jump links (including but not limited to hyperlinks, QR codes, passwords, etc.), which are intended to provide more information and save screening time, but the results are for reference only. Please note that all articles on this site contain this statement

The above is the detailed content of Bosch starts manufacturing inverters and electric motors to support electric vehicle production with 800V technology. For more information, please follow other related articles on the PHP Chinese website!

IIS unexpected error 0x8ffe2740 solution

IIS unexpected error 0x8ffe2740 solution

flac format

flac format

What are the e-commerce platforms?

What are the e-commerce platforms?

The difference between ++a and a++ in c language

The difference between ++a and a++ in c language

Where should I fill in my place of birth: province, city or county?

Where should I fill in my place of birth: province, city or county?

What is the difference between 5g and 4g

What is the difference between 5g and 4g

How to use btbook magnetic search

How to use btbook magnetic search

How to configure the path environment variable in java

How to configure the path environment variable in java