Technology peripherals

Technology peripherals

It Industry

It Industry

Toyota Motor: Reasons behind suspension of production at 14 factories revealed

Toyota Motor: Reasons behind suspension of production at 14 factories revealed

Toyota Motor: Reasons behind suspension of production at 14 factories revealed

News on September 6, Toyota Motor Corporation issued a statement today, revealing the root cause of the suspension of production at its 14 factories in Japan. According to the company, the shutdown was mainly due to problems caused by routine system maintenance work, rather than a cyberattack.

According to a company statement, the failure resulted from system maintenance and database consolidation work. During system maintenance on August 27, the system stopped functioning due to insufficient disk space, causing the backup machine to suffer a similar failure. This system manages production and parts orders, among other tasks.

The factory suspended production from the morning of August 29 to the evening of August 30, lasting two days in total, affecting the production of approximately 14,000 vehicles. These include the production lines of Toyota's best-selling models such as Corolla, Camry, and Prius Hybrid.

A Toyota spokesman said that due to a system failure, the factory was unable to continue ordering required auto parts, which affected the normal operation of 28 assembly lines. The company is currently taking steps to increase production on future operating days to compensate for the impact.

According to the editor’s understanding, Toyota Motor Corporation emphasized that they have found the root cause of the system failure and will further review the maintenance work procedures to ensure that similar problems will not occur again. The company apologized to affected partner manufacturers and consumers and said they are making every effort to resume normal production.

The above is the detailed content of Toyota Motor: Reasons behind suspension of production at 14 factories revealed. For more information, please follow other related articles on the PHP Chinese website!

Hot AI Tools

Undresser.AI Undress

AI-powered app for creating realistic nude photos

AI Clothes Remover

Online AI tool for removing clothes from photos.

Undress AI Tool

Undress images for free

Clothoff.io

AI clothes remover

Video Face Swap

Swap faces in any video effortlessly with our completely free AI face swap tool!

Hot Article

Hot Tools

Notepad++7.3.1

Easy-to-use and free code editor

SublimeText3 Chinese version

Chinese version, very easy to use

Zend Studio 13.0.1

Powerful PHP integrated development environment

Dreamweaver CS6

Visual web development tools

SublimeText3 Mac version

God-level code editing software (SublimeText3)

Hot Topics

1387

1387

52

52

What is the reason why screencasting fails? 'A must-read for newbies: How to solve the problem of unsuccessful wireless screencasting connection'

Feb 07, 2024 pm 05:03 PM

What is the reason why screencasting fails? 'A must-read for newbies: How to solve the problem of unsuccessful wireless screencasting connection'

Feb 07, 2024 pm 05:03 PM

Why does wireless screencasting fail to connect? Some friends have reported that the connection fails when using wireless screen mirroring. What is going on? What should I do if the wireless screen mirroring connection fails? Please confirm whether your computer, TV and mobile phone are connected to the same WiFi network. Screen mirroring software requires devices to be on the same network to work properly, and Quick Screen Mirroring is no exception. Therefore, please quickly check your network settings. It is important to determine whether the screen mirroring function is supported. Smart TVs and mobile phones usually support DLNA or AirPlay functionality. If the screencast function is not supported, screencasting will not be possible. Confirm whether the device is connected correctly: There may be multiple devices under the same WiFi. Make sure you are connecting to the device you want to share the screen with. 4. Ensure that the network

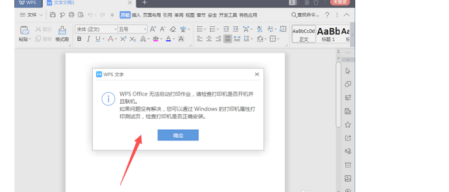

What causes WPS Office to be unable to start a print job?

Mar 20, 2024 am 09:52 AM

What causes WPS Office to be unable to start a print job?

Mar 20, 2024 am 09:52 AM

When connecting a printer to a local area network and starting a print job, some minor problems may occur. For example, the problem "wpsoffice cannot start the print job..." occasionally occurs, resulting in the inability to print out files, etc., delaying our work and study, and causing a bad impact. , let me tell you how to solve the problem that wpsoffice cannot start the print job? Of course, you can upgrade the software or upgrade the driver to solve the problem, but this will take you a long time. Below I will give you a solution that can be solved in minutes. First of all, I noticed that wpsoffice cannot start the print job, resulting in the inability to print. To solve this problem, we need to investigate one by one. Also, make sure the printer is powered on and connected. Generally, abnormal connection will cause

Comprehensive Guide to PHP 500 Errors: Causes, Diagnosis and Fixes

Mar 22, 2024 pm 12:45 PM

Comprehensive Guide to PHP 500 Errors: Causes, Diagnosis and Fixes

Mar 22, 2024 pm 12:45 PM

A Comprehensive Guide to PHP 500 Errors: Causes, Diagnosis, and Fixes During PHP development, we often encounter errors with HTTP status code 500. This error is usually called "500InternalServerError", which means that some unknown errors occurred while processing the request on the server side. In this article, we will explore the common causes of PHP500 errors, how to diagnose them, and how to fix them, and provide specific code examples for reference. Common causes of 1.500 errors 1.

Why is Apple mobile phone charging so slow?

Mar 08, 2024 pm 06:28 PM

Why is Apple mobile phone charging so slow?

Mar 08, 2024 pm 06:28 PM

Some users may encounter slow charging speeds when using Apple phones. There are many reasons for this problem. It may be caused by low power of the charging device, device failure, problems with the USB interface of the mobile phone, or even battery aging and other factors. Why does Apple mobile phone charge very slowly? Answer: charging equipment problem, mobile phone hardware problem, mobile phone system problem. 1. When users use charging equipment with relatively low power, the charging speed of the mobile phone will be very slow. 2. Using third-party inferior chargers or charging cables will also cause slow charging. 3. It is recommended that users use the official original charger, or replace it with a regular certified high-power charger. 4. There is a problem with the user’s mobile phone hardware. For example, the USB interface of the mobile phone cannot be contacted.

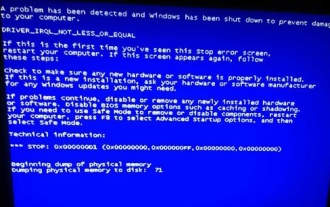

Revealing the root causes of win11 blue screen

Jan 04, 2024 pm 05:32 PM

Revealing the root causes of win11 blue screen

Jan 04, 2024 pm 05:32 PM

I believe many friends have encountered the problem of system blue screen, but I don’t know what is the cause of win11 blue screen. In fact, there are many reasons for system blue screen, and we can investigate and solve them in order. Reasons for win11 blue screen: 1. Insufficient memory 1. It may occur when running too many software or the game consumes too much memory. 2. Especially now there is a memory overflow bug in win11, so it is very likely to be encountered. 3. At this time, you can try to set up virtual memory to solve the problem, but the best way is to upgrade the memory module. 2. CPU overclocking and overheating 1. The causes of CPU problems are actually similar to those of memory. 2. It usually occurs when using post-processing, modeling and other software, or when playing large-scale games. 3. If the CPU consumption is too high, a blue screen will appear.

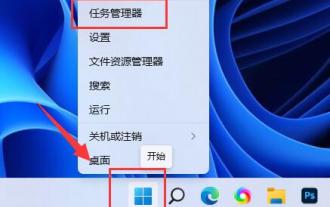

Why does win11 shut down automatically?

Jan 01, 2024 pm 11:39 PM

Why does win11 shut down automatically?

Jan 01, 2024 pm 11:39 PM

Recently, a friend encountered the problem of Win11 automatically shutting down after updating the system. In many cases, it happens when playing games. I don’t know what caused it. In fact, this may be caused by insufficient computer configuration or system failure. Let’s take a look at the causes and solutions. Why does win11 automatically shut down? 1. Insufficient configuration 1. Windows 11 system has higher CPU and memory requirements than Windows 10. 2. Especially when running large-scale games and other tasks, it is very easy to automatically shut down. 3. Users can try to restore the usage status before automatic shutdown by right-clicking the start menu icon and opening the "Task Manager" page. 4. Let’s check the CPU, memory, and disk on this page.

Troubleshooting the causes and solutions for HTTP status code 550

Feb 20, 2024 am 09:49 AM

Troubleshooting the causes and solutions for HTTP status code 550

Feb 20, 2024 am 09:49 AM

Explore the causes and solutions of HTTP status code 550 Introduction: In network communications, HTTP status codes play an important role and are used to indicate the results of the server processing the request. Among them, HTTP status code 550 is a relatively rare status code that is usually related to the server refusing to execute the request. This article will explore the causes of HTTP status code 550 and provide solutions. 1. The basic concept of HTTP status code. Before understanding the HTTP status code 550, let us first briefly understand the basic concept of HTTP status code.

Reasons and analysis of win10 driver installation failure

Jan 02, 2024 pm 04:57 PM

Reasons and analysis of win10 driver installation failure

Jan 02, 2024 pm 04:57 PM

Some friends encountered the problem of installation failure when installing Windows 10 drivers, but they did not know the cause of the failure or how to solve it. There are several different reasons for this problem. Please follow me to find out below. Reasons why win10 driver installation fails: 1. System version Currently, Windows 10 system already has the function of automatically installing drivers. The introduction of this feature eliminates the need for users to manually search and install drivers when installing the system. The system will automatically detect and install appropriate drivers, providing a more convenient experience. If your driver installation fails, one solution is to try updating your system. This may fix some system-related issues, allowing the driver to