Currently, the traditional manual polishing method is inefficient, quality control is difficult to ensure, and product quality is uneven. Based on the advantages of independent core technology and full-production ecological chain layout, Estun has launched a complete solution for robot polishing with flexible control, high precision and convenient operation.

Traditional grinding methods are less efficient

1, The consistency of incoming materials cannot be guaranteed: Welding, casting and other processes in industrial production will cause product deformation.

2, Contact scenes have extremely high response requirements: rigid grinding, collision occurs "in an instant".

3, The grinding process is extremely complex: There are many types of tools and abrasives, there are no standards for grinding requirements, and the process data relies on experience.

A new generation of polishing technology: the integration of robots and force control

The grinding process has higher requirements on the contact accuracy and response speed of the robot. It not only tests the trajectory accuracy and rigidity of the robot, but also requires the robot to provide a stable force. The robot's grinding force Accuracy, angle and response speed directly affect the polishing effect.

Eston has complete solutions in the field of metal processing, and has industry-leading advantages in bending, welding, sheet metal, grinding and polishing and other fields. Based on its profound technological accumulation in the field of polishing, Eston launched "Robot Force Control Integration" complete solution for polishing.

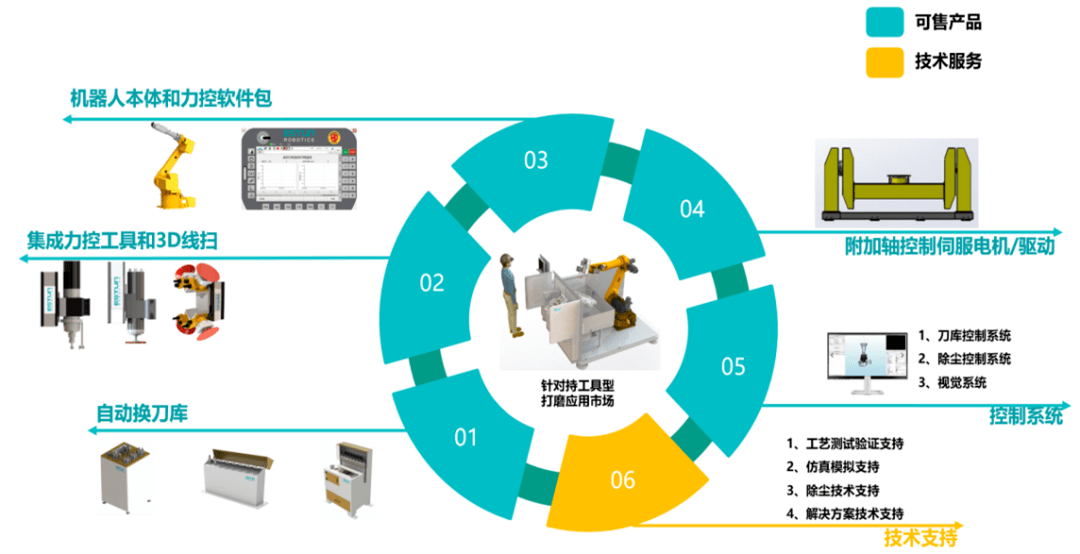

Integrated product ecology of robots and force control tools

Compared with the traditional tool-holding grinding method, Eston integrated grinding solution integrates the advantages of high flexibility, high automation, and high adaptability of robots, force-controlled tools, and laser vision into the grinding solution , developed a flexible polishing solution with tactile and visual sensitivity. It applies different polishing forces according to different material workpieces and different polishing positions. It also has a certain degree of flexibility to make up for the problem of material inconsistency and deeply solve the industry's pain points.

Five major product advantages

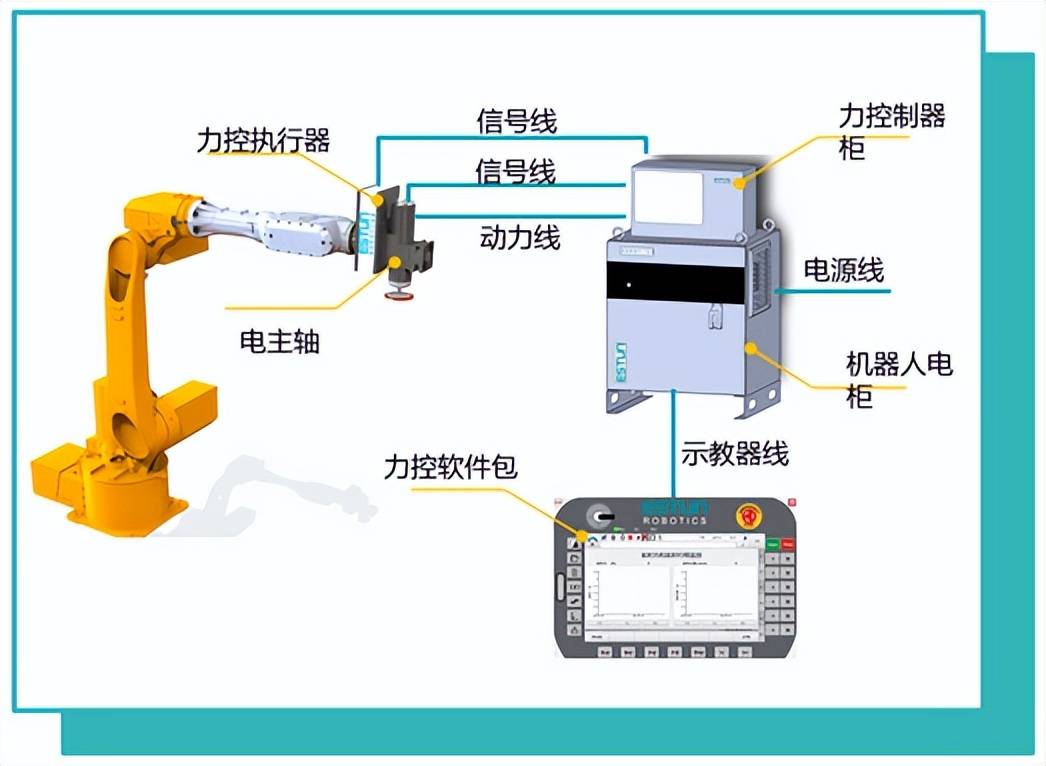

1. Super easy to use--simple installation and easy debugging

Modular assembly, simple installation and convenient debugging. A teaching pendant can complete the debugging of the robot and peripheral products.

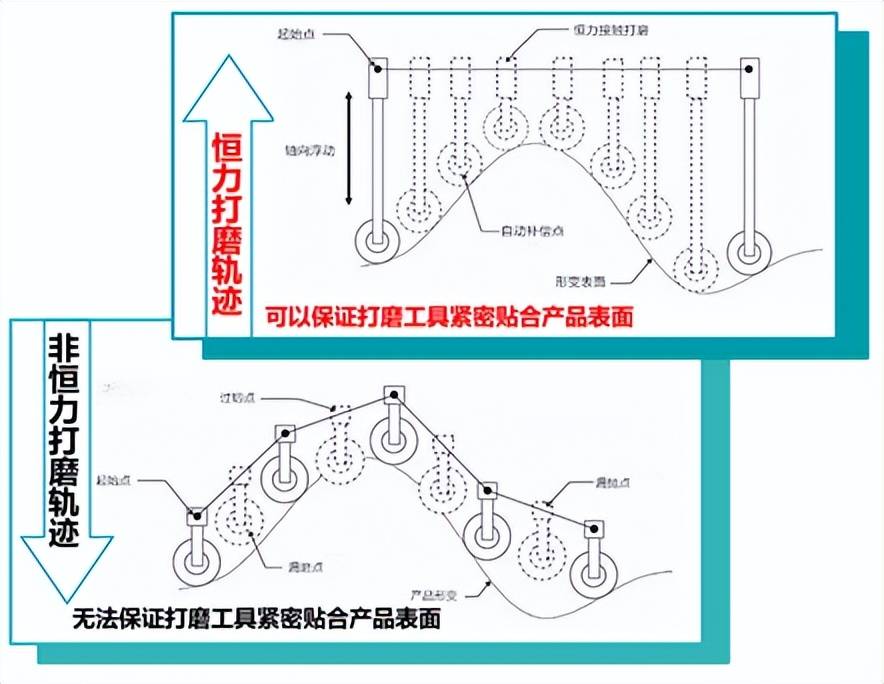

2. Adaptive--the first in the industry, automatic trajectory adjustment

The laser system recognizes surface contour changes and adaptively adjusts the robot posture to ensure stable fit between the tool and the workpiece surface.

3. Super perception--constant force floating, precise perception

· The micro-power execution system compensates for changes in the workpiece surface contour in real time to ensure stable tracking of the tool and the workpiece surface.

· Real-time feedback, adjustment and accurate execution of the preset contact force ensures that the surface contact force accuracy of the robot in any posture is within 1N.

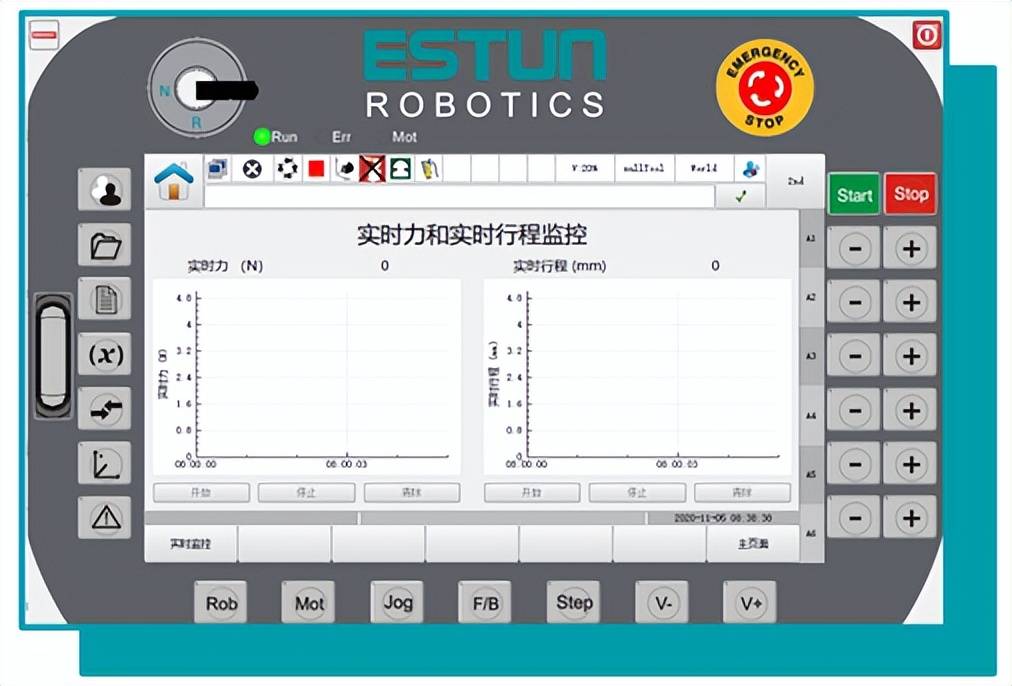

4. Comprehensive integration - real-time display, expanded operating boundaries

Eston’s integrated force control software package can display the force and stroke of the force position actuator in real time, and can also control the grinding tools and the automated operation of peripheral products, such as positioners, dust removal rooms, and floor rails. , tool magazine and other equipment control.

5. Super worry-free - ten years of accumulation, eliminating the worries of landing

Eston has been deeply involved in grinding technology for more than 10 years, accumulated rich experience in grinding technology, and provided a variety of industry solutions. We provide more flexible, convenient and high-precision intelligent polishing complete solutions for the automotive, ceramics, machinery, new materials and other industries

For Eston Automation’s continued attention, we will launch a complete solution for force control integration in the next issue!

The above is the detailed content of New integrated polishing solution: robot + force control, achieving high flexibility, high precision and high efficiency!. For more information, please follow other related articles on the PHP Chinese website!

c language else if statement usage

c language else if statement usage

How to take screenshots on computer

How to take screenshots on computer

How to connect asp to access database

How to connect asp to access database

pycharm find file method

pycharm find file method

How to set up WeChat anti-blocking function

How to set up WeChat anti-blocking function

How about MEX exchange

How about MEX exchange

How to solve the problem that win11 antivirus software cannot be opened

How to solve the problem that win11 antivirus software cannot be opened

Which platform is better for virtual currency trading?

Which platform is better for virtual currency trading?