Technology peripherals

Technology peripherals

AI

AI

The core components of humanoid robots? This sensor company will bring innovative products to the Industrial Expo. Watch quickly.

The core components of humanoid robots? This sensor company will bring innovative products to the Industrial Expo. Watch quickly.

The core components of humanoid robots? This sensor company will bring innovative products to the Industrial Expo. Watch quickly.

After three years of preparation, careful polishing and accumulation, the appearance of many brands in this CIIF is amazing

With the digital transformation of the global manufacturing industry, the in-depth implementation of intelligent manufacturing projects and the acceleration of the transformation and upgrading of traditional industries, the demand for emerging production tools such as robots has become increasingly urgent

The exhibition area setting of this CIIF is highly in line with the trend of the times and historical trends in the development of new global industrialization. Among them, the robot exhibition area reaches 53,000 square meters, which has become a worldwide The largest robot industry chain platform in China.

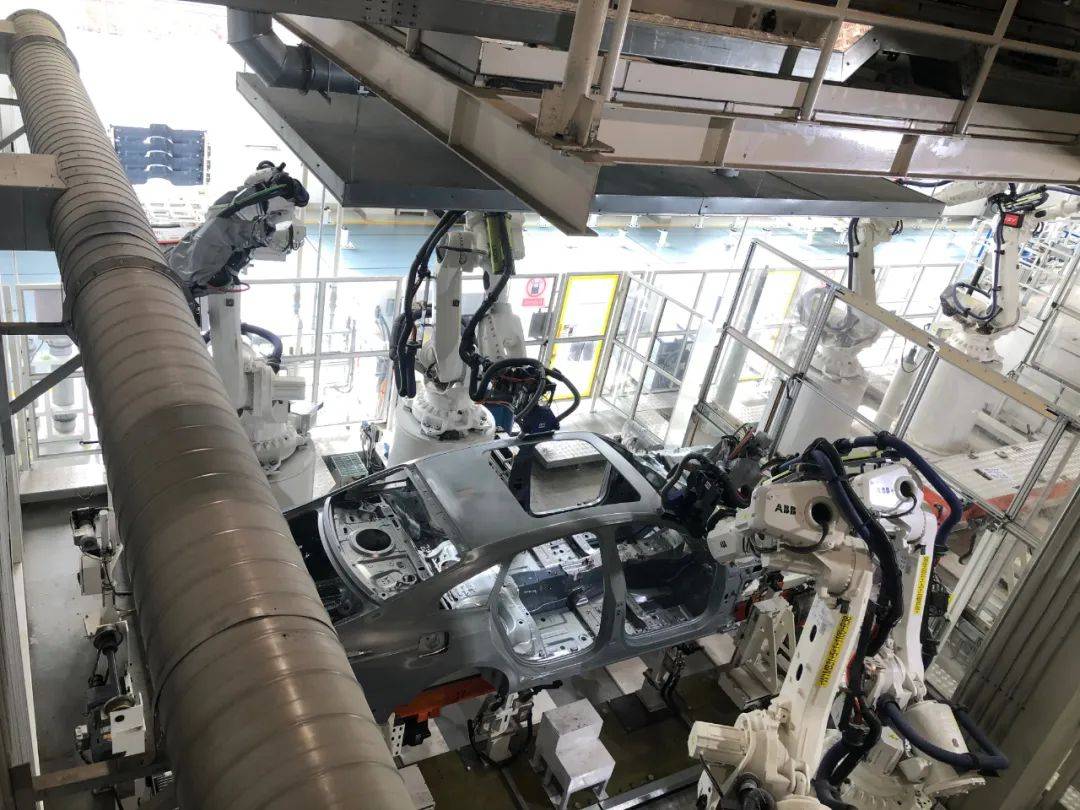

The robot exhibition of this CIIF not only brings together the "four major families" of FANUC, ABB, KUKA and Yaskawa Robots, as well as domestic robots such as Eston, New Star, Jieka and Siasong. The leading company in complete machinery also has many new products and new ways to improve quality and efficiency and achieve high-quality development.

For example, many capabilities and solutions were demonstrated to promote strong and complementary chains and continuously improve the resilience of the industrial chain and supply chain, as well as breakthroughs in the localization of some major technical equipment, core components, basic processes, etc., It reflects the current new trend of digitalization, intelligence and low-carbon development of manufacturing industry.

Force sensors play a vital role in the robot industry. They are not only a key factor in promoting the further development of the industry, but also become a high-profile highlight project at this industry expo

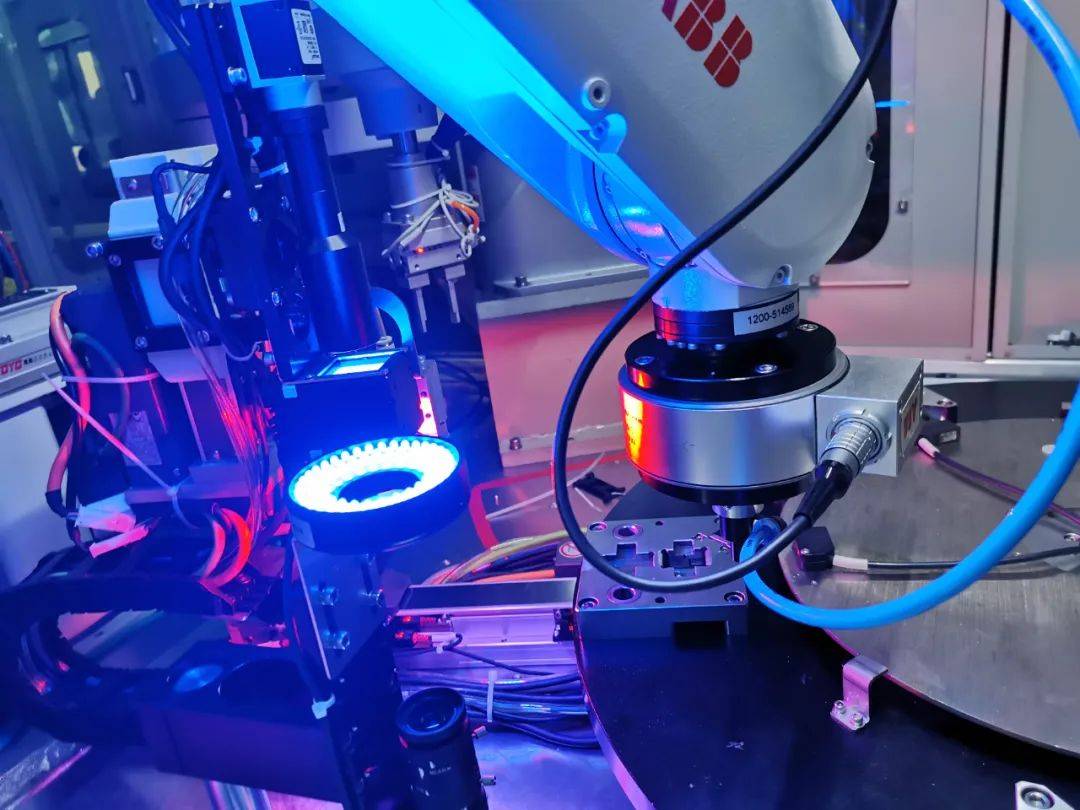

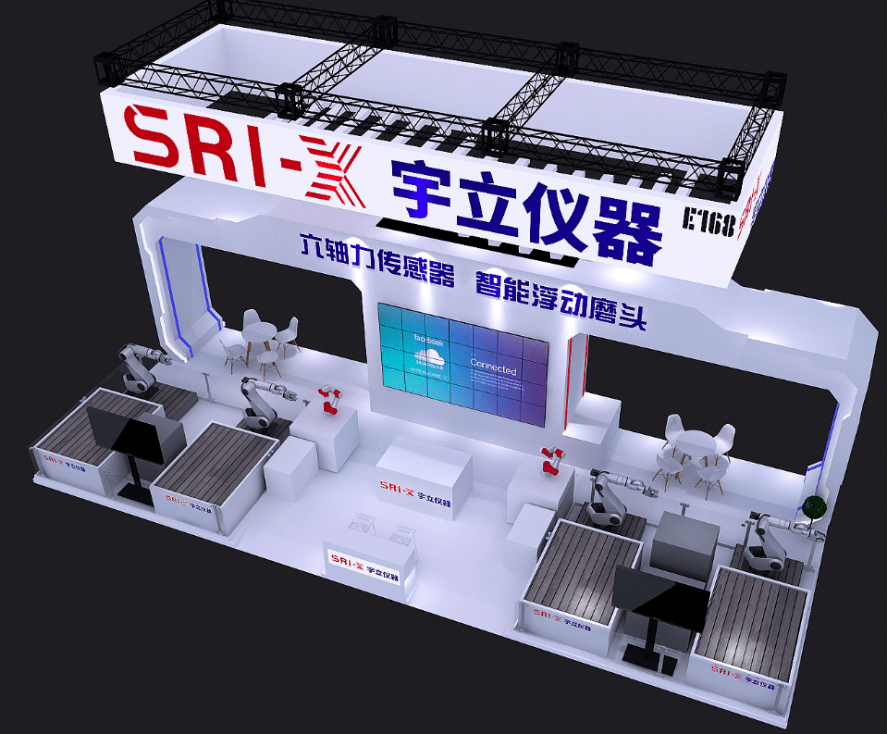

Robot Lecture Hall learned that this time the world's most advanced six-axis force sensor and intelligent force-controlled polishing manufacturer[Yuli Instruments] will bring a variety of exhibits at the 8.1H E168 booth. A comprehensive visual feast will be prepared for the audience.

Force sensor products have many highlights

Sensors have become an indispensable key driving force in today's robotics and other technological fields. This seemingly small product is known as the neural antennae of modern intelligence and is an important component of the era of the Internet of Everything. part.

The application range of sensors is very broad, whether it is robots, smartphones, automobiles, industrial automation or medical equipment. As a device that can sense, measure and monitor variables in the environment, sensors can greatly facilitate people's production and Life is almost everywhere.

In recent years, with the rapid development of the robot industry, sensors have ushered in new opportunities and put forward targeted requirements. Sensors have begun to become smaller, lower power consumption, higher precision, and more reliable and Durable, this flexibility allows the sensor to be used in a wider variety of fields. For example, Yuli Instruments' sensors are not only used in the products of most automobile companies around the world, are also recognized by companies such as Medtronic, ABB, KUKA, YASKAWA, and university research institutes, helping these companies to steadily improve. determines the maturity of emerging products.

high-end and intelligent development. Technology, Most of these technologies are inseparable from the use of sensors, a new product.

Yuli’s various six-dimensional force sensors and joint torque sensors have become hot spots at the exhibition many timesAs the largest force sensor manufacturer in the Chinese market,

Yuli continues to innovate products every year and actively launches new models of sensors. It hopes to promote technological innovation and development in downstream industries such as robotics by further improving the performance and adaptability of sensors. Since innovation requires long-term accumulation of technology and craftsmanship, the strong ones in this field often remain strong, with obvious differences in product category expansion and technical strength, and Yuli is undoubtedly the leader among them.

Yuli’s various sensorsare showing increasingly powerful capabilities in terms of sampling speed, accuracy and consistency. For example, at this industry expo, Yuli not only statically displayed a batch of joint torque sensors and a batch of six-dimensional force sensors, but also dynamically displayed the actual data of the six-dimensional force sensors. The scene can be more intuitive and intuitive. The computer data shows the high-precision and low-latency characteristics of Yuli's six-dimensional force sensor.

The widespread application of these new sensors has further promoted the development of robotics technology. For example, Yuli's six-dimensional force sensors have been widely used in the field of robotics. Currently, Yuli's six-dimensional force sensors are mainly used in industrial robots, medical robots, etc.

More innovations are on the way

Yuli’s six-dimensional force sensor has become an important component of collaborative robots from many manufacturers to achieve machine compliance and intelligent control. For exampleIn the field of industrial manufacturing, by being installed at the end of collaborative robots, robot manufacturers can use six-dimensional force sensors to better implement applications such as high-precision flexible assembly, welding, deburring operations, and drag teaching. In the medical field, Yuli's six-dimensional force sensor can also help surgical robots sense real-time parameters of all aspects of the human body, including strength, weight, etc., thereby achieving more precise and high-quality surgical operations and reducing surgical costs. risk.

The huge market demand is also one of the important factors why Yuli has attracted much attention. According to Statista, the global sensor market size has reached US$251.29 billion (approximately RMB 1.79 trillion) in 2022. Although affected by the epidemic, the global sensor market has experienced significant fluctuations in recent years. The year-on-year growth rate fell by 13% in 2020, but it rapidly increased by 62% year-on-year in 2021, and by 10% in 2022. In the past, the global sensor market was relatively fragmented, dominated by leading overseas manufacturers. The rapid growth in recent years has provided new opportunities for rising stars.

Especially for companies that have rapidly penetrated into the Chinese market, their market performance has been outstanding in recent years, and they have received increasing recognition from capital and the market. The Chinese market has benefited from a sharp increase in demand in recent years, with growth rates reaching 14%, 20%, and 19% respectively in3 years, maintaining around 20%. In addition, the proportion of the Chinese market in the global sensor market has also remained at around 20%, and its share in the global market is also relatively high.

makes the value of technology more prominent, and also provides greater market opportunities for latecomers. , bringing broader technological innovation value.

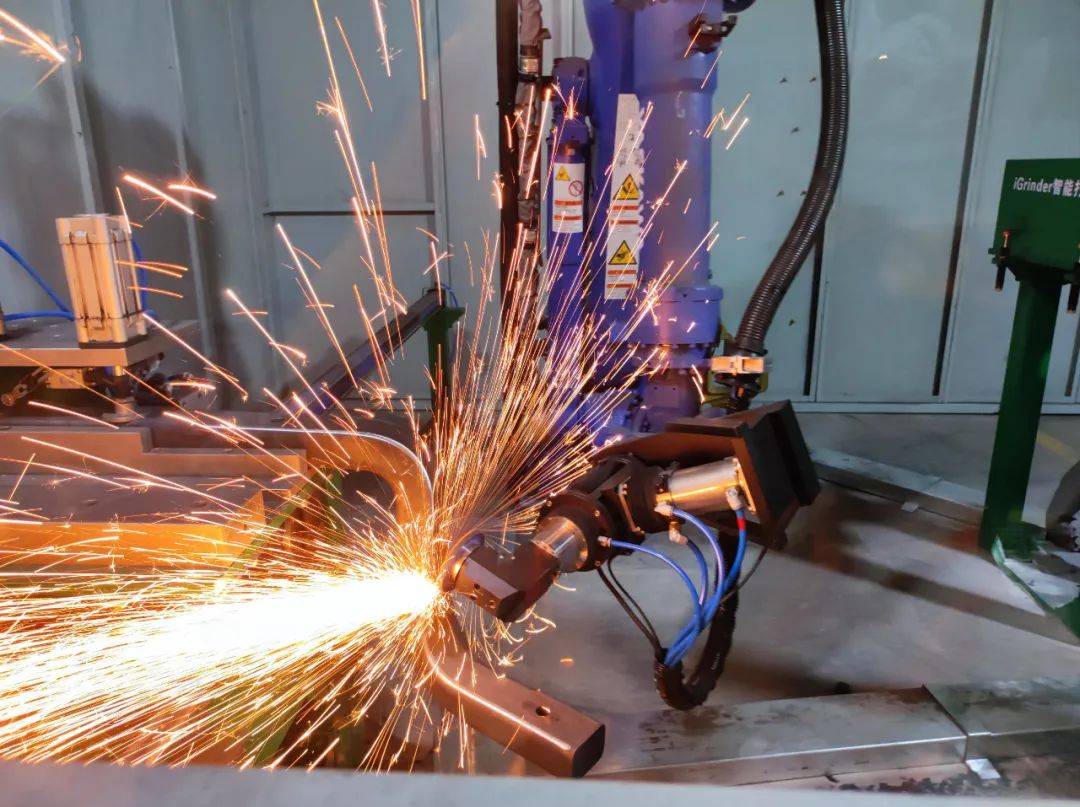

For example, ABB robots and KUKA robots have unique advantages in the field of grinding and polishing. When ABB robots perform such processes, the grinding quality and product finish are more outstanding than similar products, and product consistency is quite advantageous. The end grinding kits of these two top companies actually use the Yuli iGrinder® intelligent floating grinding head product. iGrinder® is a force-controlled grinding system independently developed by Yuli in response to market demand.In terms of function, iGrinder® does not need to rely on robot force control software. When used with robots for grinding, polishing and other applications, the user only needs to input the required force value to complete the force control and floating functions by itself. This means that the robot only needs to move according to the taught trajectory to easily realize intelligent force-controlled polishing, thereby

reducing the requirements for workers’ operating skills, reducing the labor pressure of enterprises, and also shortening product modifications The preparation period for replacement is reduced and the corresponding equipment investment is reduced.

iGrinder® intelligent floating grinding head has a unique design, and its innovative core technology enables it to better achieve high-precision grinding operations. Excellent grinding results are achieved both at high and low speeds, thanks to the axial floating system that ensures continued precision and stability under all operating conditions. In addition, the adaptive control system of this grinding head can adjust the grinding pressure in real time to ensure the smoothness of the grinding surface, further improving the grinding quality and efficiency

In addition to this grinding head, Yuli has also integrated its accumulation and industry experience in force-controlled grinding to create multiple application workstations and process suites, creating a more diversified product matrix to facilitate more Procurement and use by multiple customers.

It is reported that at this Industrial Expo, Yuli will display belt machine grinding application station, friction stir welding grinding application station, radial floating grinding application station, dual-axis grinding tool application station, Burr tools and many other applications can better meet the differentiated needs in the current market. These exhibits also demonstrate the comprehensive business characteristics of Yuli's own sensor chip, module and software integrated solutions.

The domestic substitution potential of sensors is very huge

This year’s CIIF is a comprehensive exhibition, where companies explore the world’s cutting-edge technologies, major original innovative technologies and application scenarios

For example, humanoid robots are an important direction that the industry is paying great attention to. The development of this type of robots has shown the characteristics of multi-information fusion. In order to achieve precise control, humanoid robots need to be equipped with force sensors and other products to achieve wider force control, especially six-dimensional torque sensors on the wrists, ankles, etc., to achieve more dexterous perception.

With the continuous development of robot force control technology, sensors play an important role in the field of humanoid robots, and the market application potential has significantly increased, becoming an important opportunity to promote future technological and industrial development

The innovative sensor products brought by Yuli not only demonstrate the latest achievements in industrial robot technology, but also herald the unlimited potential of the humanoid and even more robot industries in the future

Judging from the development trends and technological change routes conveyed by Yuli Instrument’s exhibits, future sensors have begun to be updated and upgraded along the technical paths of integration, safety, intelligence and self-adaptation, miniaturization and low power consumption. .

We look forward to Yuli’s continuous technological innovation, which can quickly apply these technologies to various types of robots, further promote the development of the robot industry, and bring more convenience and surprises to our lives. Welcome all readers to come to Yuli Booth 8.1H E168 to visit and exchange ideas at this Industrial Expo.

The above is the detailed content of The core components of humanoid robots? This sensor company will bring innovative products to the Industrial Expo. Watch quickly.. For more information, please follow other related articles on the PHP Chinese website!

Hot AI Tools

Undresser.AI Undress

AI-powered app for creating realistic nude photos

AI Clothes Remover

Online AI tool for removing clothes from photos.

Undress AI Tool

Undress images for free

Clothoff.io

AI clothes remover

AI Hentai Generator

Generate AI Hentai for free.

Hot Article

Hot Tools

Notepad++7.3.1

Easy-to-use and free code editor

SublimeText3 Chinese version

Chinese version, very easy to use

Zend Studio 13.0.1

Powerful PHP integrated development environment

Dreamweaver CS6

Visual web development tools

SublimeText3 Mac version

God-level code editing software (SublimeText3)

Hot Topics

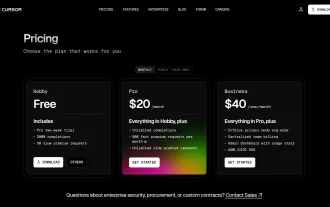

I Tried Vibe Coding with Cursor AI and It's Amazing!

Mar 20, 2025 pm 03:34 PM

I Tried Vibe Coding with Cursor AI and It's Amazing!

Mar 20, 2025 pm 03:34 PM

Vibe coding is reshaping the world of software development by letting us create applications using natural language instead of endless lines of code. Inspired by visionaries like Andrej Karpathy, this innovative approach lets dev

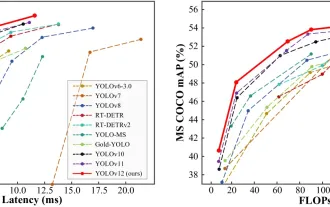

How to Use YOLO v12 for Object Detection?

Mar 22, 2025 am 11:07 AM

How to Use YOLO v12 for Object Detection?

Mar 22, 2025 am 11:07 AM

YOLO (You Only Look Once) has been a leading real-time object detection framework, with each iteration improving upon the previous versions. The latest version YOLO v12 introduces advancements that significantly enhance accuracy

How to Use DALL-E 3: Tips, Examples, and Features

Mar 09, 2025 pm 01:00 PM

How to Use DALL-E 3: Tips, Examples, and Features

Mar 09, 2025 pm 01:00 PM

DALL-E 3: A Generative AI Image Creation Tool Generative AI is revolutionizing content creation, and DALL-E 3, OpenAI's latest image generation model, is at the forefront. Released in October 2023, it builds upon its predecessors, DALL-E and DALL-E 2

Top 5 GenAI Launches of February 2025: GPT-4.5, Grok-3 & More!

Mar 22, 2025 am 10:58 AM

Top 5 GenAI Launches of February 2025: GPT-4.5, Grok-3 & More!

Mar 22, 2025 am 10:58 AM

February 2025 has been yet another game-changing month for generative AI, bringing us some of the most anticipated model upgrades and groundbreaking new features. From xAI’s Grok 3 and Anthropic’s Claude 3.7 Sonnet, to OpenAI’s G

Elon Musk & Sam Altman Clash over $500 Billion Stargate Project

Mar 08, 2025 am 11:15 AM

Elon Musk & Sam Altman Clash over $500 Billion Stargate Project

Mar 08, 2025 am 11:15 AM

The $500 billion Stargate AI project, backed by tech giants like OpenAI, SoftBank, Oracle, and Nvidia, and supported by the U.S. government, aims to solidify American AI leadership. This ambitious undertaking promises a future shaped by AI advanceme

Google's GenCast: Weather Forecasting With GenCast Mini Demo

Mar 16, 2025 pm 01:46 PM

Google's GenCast: Weather Forecasting With GenCast Mini Demo

Mar 16, 2025 pm 01:46 PM

Google DeepMind's GenCast: A Revolutionary AI for Weather Forecasting Weather forecasting has undergone a dramatic transformation, moving from rudimentary observations to sophisticated AI-powered predictions. Google DeepMind's GenCast, a groundbreak

Sora vs Veo 2: Which One Creates More Realistic Videos?

Mar 10, 2025 pm 12:22 PM

Sora vs Veo 2: Which One Creates More Realistic Videos?

Mar 10, 2025 pm 12:22 PM

Google's Veo 2 and OpenAI's Sora: Which AI video generator reigns supreme? Both platforms generate impressive AI videos, but their strengths lie in different areas. This comparison, using various prompts, reveals which tool best suits your needs. T

Which AI is better than ChatGPT?

Mar 18, 2025 pm 06:05 PM

Which AI is better than ChatGPT?

Mar 18, 2025 pm 06:05 PM

The article discusses AI models surpassing ChatGPT, like LaMDA, LLaMA, and Grok, highlighting their advantages in accuracy, understanding, and industry impact.(159 characters)