On September 19, Yuejiang’s 2023 new product launch conference arrived in Shanghai as scheduled. The new generation of collaborative robots CRA series, CRAS series and the rewritten content are: VX500 smart camera was officially released.

TheA (Advanced) of the CRA series represents advanced, which not only greatly enhances the ease of use and safety, but also greatly improves the efficiency, better adapting to the high speed and high speed in industrial production. Precision application further expands the application scope of robots.

At the same time, the 2.5D vision smart camera VX500 released this time is adapted to the CRA series to achieve plug-and-play, solving industry problems such as difficult deployment and operation of manufacturing vision applications.

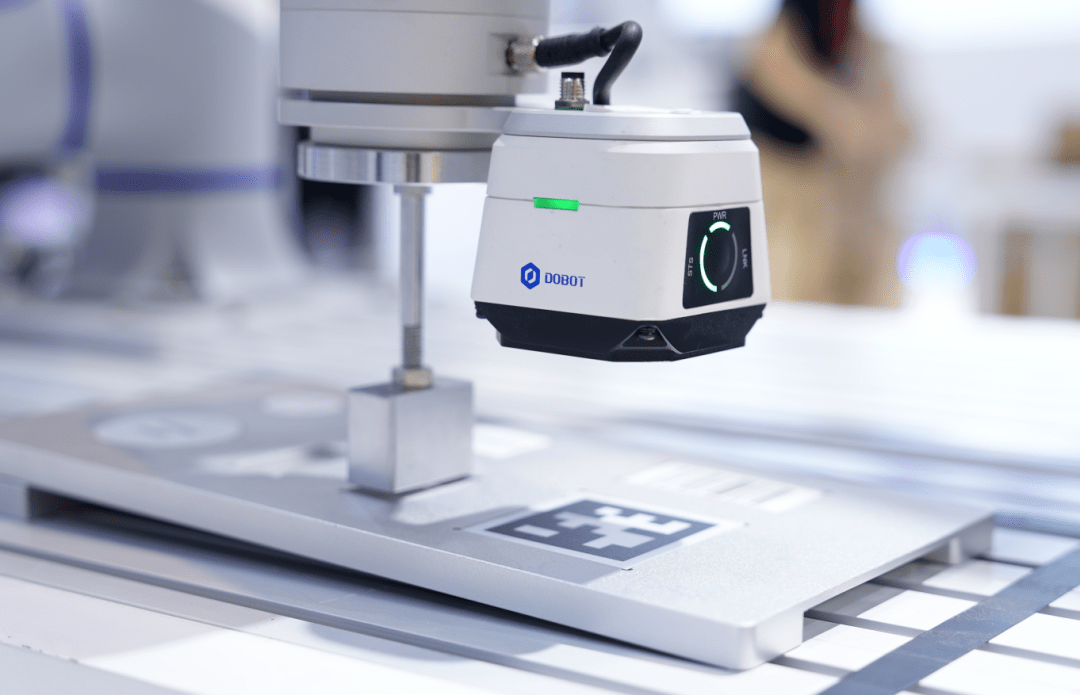

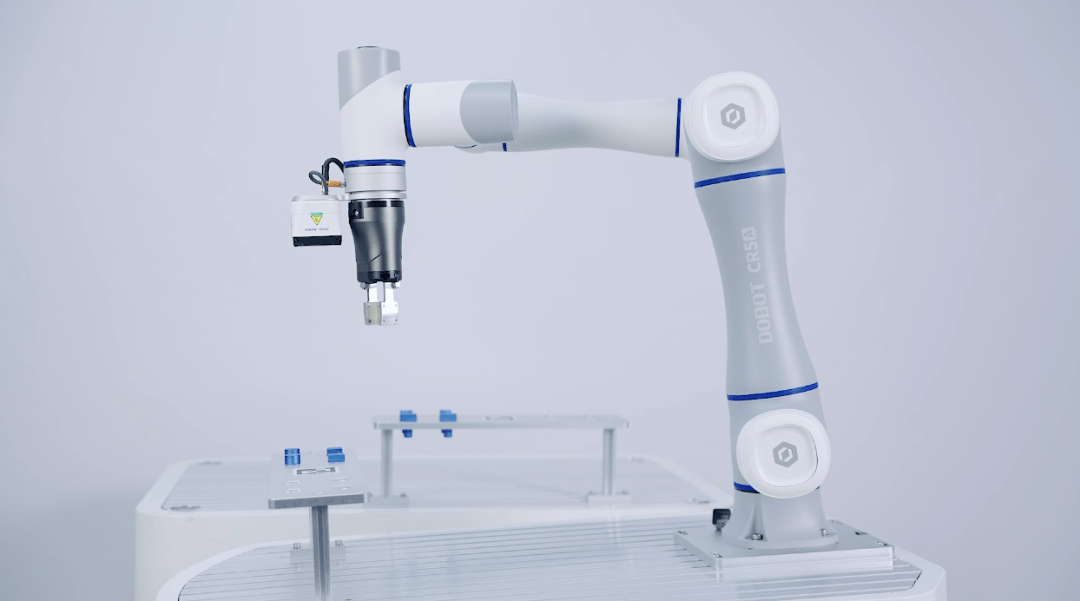

The content that needs to be rewritten is: CRA series collaborative robot

The rewritten content is: New standards for cooperation

More efficient

Adopting Yuejiang’s self-developed high-performance integrated joint technology and integrating advanced vibration suppression algorithms, the maximum speed of the robot joints is increased to 223°/s, and the jitter under high-speed movement is reduced to less than 0.3mm, achieving a motion rhythm of 25 %, the operation efficiency is higher.

In order to re-express the content more accurately, the language needs to be changed to Chinese. There is no need to appear the original sentence

Optimize the precision control algorithm to achieve micron-level anti-shake, with repeated positioning accuracy up to ±0.02mm. It can still guarantee 0.2 - 0.4mm absolute positioning accuracy under complex posture changes, improving production yield.

What needs to be rewritten is: more secure

Equipped with electromagnetic brake, supporting 18 ms fast braking, which can effectively prevent the end tool from falling by less than 1 mm when the robot is enabled up and down or encounters an unexpected power outage. Causes damage to end tools or workpieces. The CRA series also has built-in security functions such as virtual walls and real-time detection of terminal loads to ensure production safety.

When rewriting the content, the language needs to be rewritten into Chinese without changing the original meaning

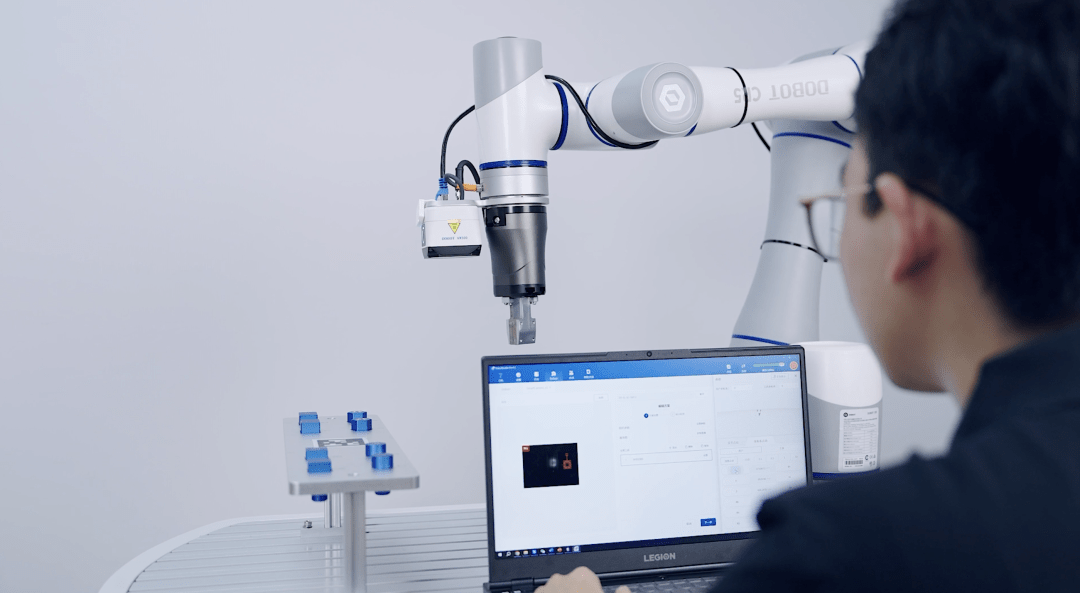

The new generation DobotStudio Pro operating system adopts a new UI design, the operation is simple and efficient, supports graphics, script programming and trajectory reproduction, and is compatible with PC, Pad, mobile phone and other multi-terminal operations to meet different scenarios According to the needs, multiple 3D interactive functions have been updated to intuitively display the running status of the robot, making debugging easier.

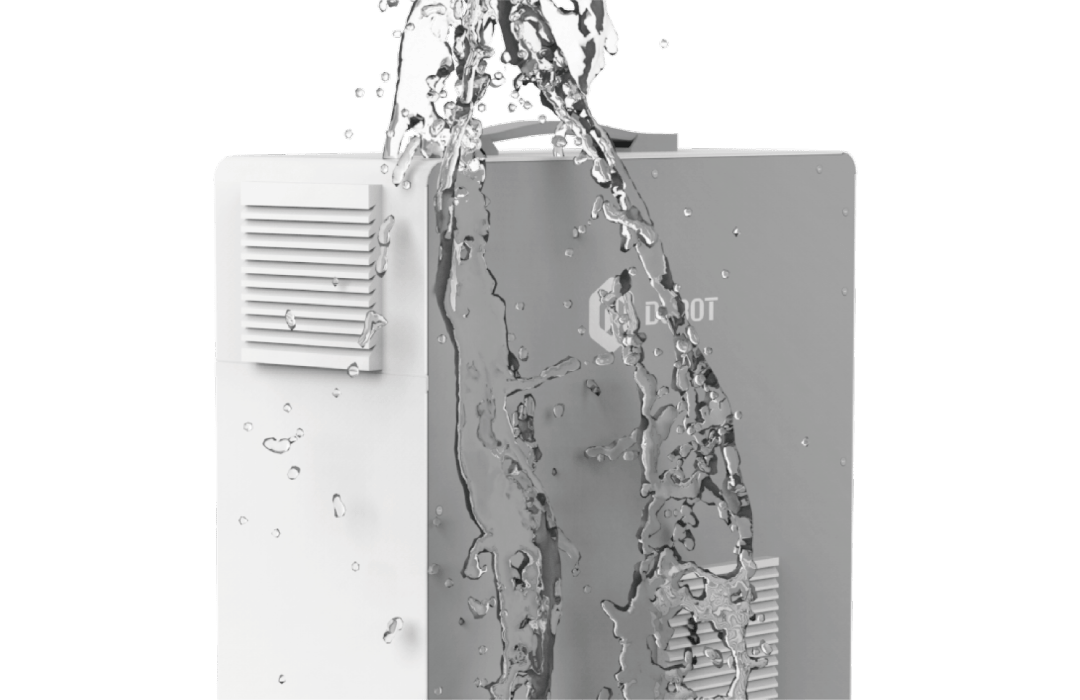

more reliable

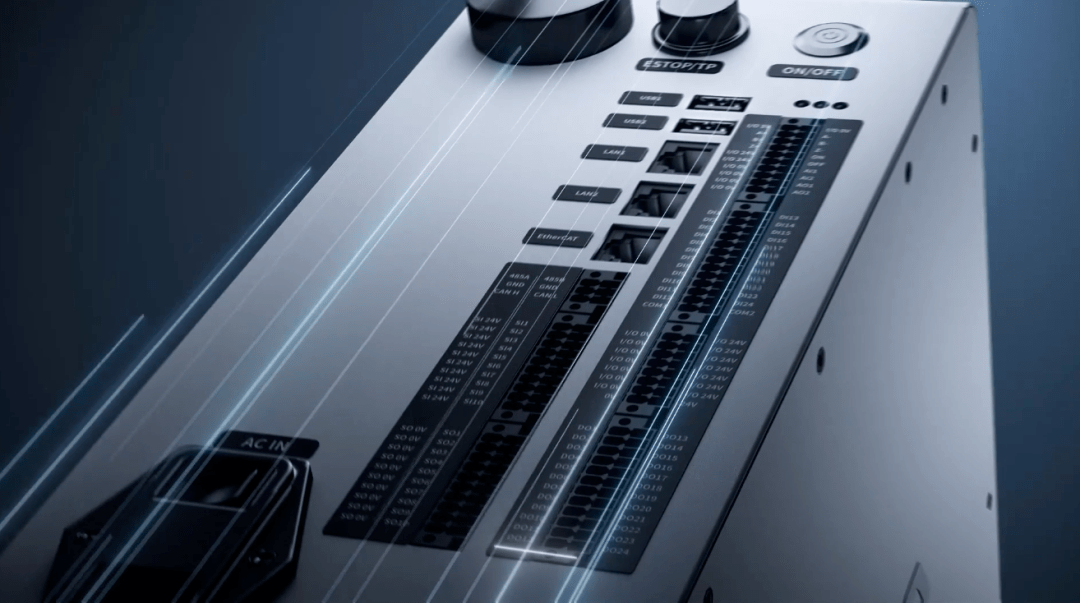

The volume of the control cabinet is reduced by 20%, The weight is reduced by 20%,Optional IP54 protection version is not afraid of harsh environments such as oil pollution and dust, and reduces Later maintenance costs.

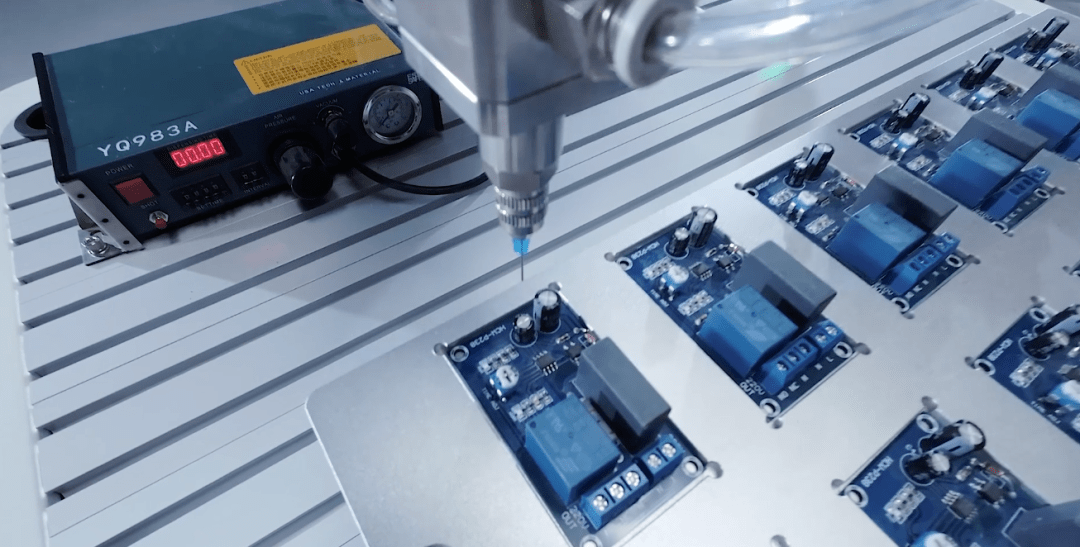

The rewritten content is: VX500 smart camera

Accurate and efficient, ready to use

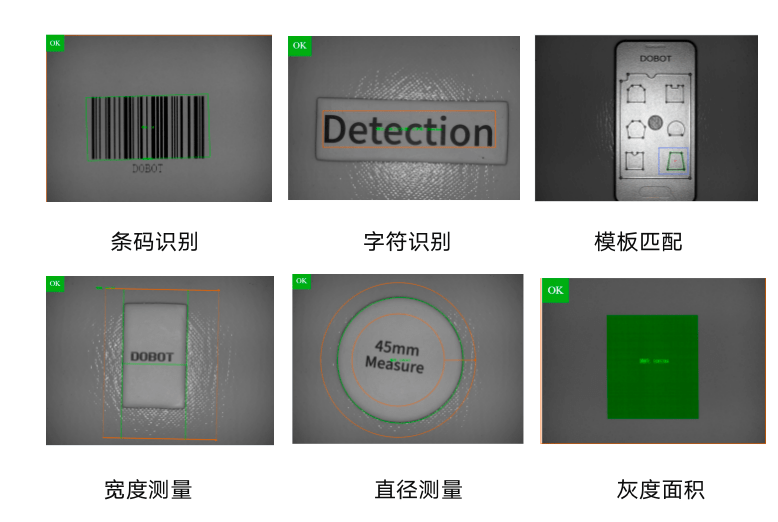

For vision applications in the manufacturing industry, there are often problems such as difficulty in selection, deployment, and operation, which also limits the expansion of collaborative robot application scenarios. At this exhibition, Yuejiang released the rewritten content: VX500 smart camera. While achieving integrated imaging, communication, and light sources, the rewritten content that needs to be realized is: CRA series collaborative robots are plug-and-play. It breaks through the industry constraints of "difficulty in implementing visual applications" and at the same time opens up a broad application space for the industry.

Accurate and efficient self-developed 2.5D algorithm

VX500 is equipped with Yuejiang’s self-developed 2.5D spatial positioning compensation algorithm, which can quickly complete positioning with an accuracy of up to ±0.26mm, solving the problem of compound robots in mobile handling, loading and unloading and other applications. Inaccurate positioning problems caused by spatial height transformation (such as uneven ground, tilt, etc.).

2.5D positioning codes have various styles. By identifying different positioning codes, an engineering script can be implemented to complete a variety of tasks

Plug and play, simple and fast

The rewritten content is: VX500 smart camera is compatible with Yuejiang CRA series collaborative robot and DobotStudio Pro software. There is no need to install additional communication modules and third-party operating software to realize robot and camera linkage. The software is simple to operate, supports calling visual functions through graphical programming, and freely matching functions to help quickly complete debugging and deployment.

In addition, the camera is also equipped with a comprehensive error-proof detection algorithm, which can realize functions such as positioning, matching, identification, and measurement. It can provide better solutions for the manufacturing processes related to diversified components on the production line and meet the visual requirements of the production line. need.

The content that needs to be rewritten is: CRAS series collaborative robot

Equipped with internationally leading safety skin

Based on the efficiency, accuracy and ease of use of the CRA series, what needs to be rewritten is: the CRAS series collaborative robot is equipped with cross-border non-contact safety skin, which can sense obstacles within a range of 15 cm in real time , achieving stop before collision, ensuring safety while increasing the robot's operating speed to 4 times the international standard. The CRAS series has three load models of 3 kg, 5 kg, and 10 kg, which can achieve both improved efficiency and safety in human-machine collaborative production.

's first product with a 0.5-20 kg payload A leading robot company in the matrix, has eight series of collaborative robots, CR, CRS, CRA, CRAS, MG400, M1Pro, Nova and Magician, and more than 20 models. The cumulative global shipments have reached 68,000 units, and are sold in 100 countries and area.

In the future, Yuejiang Robot will continue to uphold its consistent pioneering spirit, use leading technology accumulation to improve the quality and efficiency of the manufacturing industry, escort "high-quality development" and "manufacturing power", and continue to invest in R&D and With a complete service system, we strive to make Yuejiang collaborative robots a global standard for intelligent manufacturing.Original statement: Please indicate the source when reprinting this article

Disclaimer: Some pictures in this article come from the Internet,

If there is any infringement, please contact us in time to make relevant corrections.

The above is the detailed content of A new chapter in collaborative robots: CRA series released, leading the advancement of collaborative technology. For more information, please follow other related articles on the PHP Chinese website!

How to start mysql service

How to start mysql service

How to skip network connection during win11 installation

How to skip network connection during win11 installation

How to solve the problem that the phpstudy port is occupied

How to solve the problem that the phpstudy port is occupied

How to repair win7 system if it is damaged and cannot be booted

How to repair win7 system if it is damaged and cannot be booted

xenserver

xenserver

Is Code Red a computer virus?

Is Code Red a computer virus?

stackoverflowatline1

stackoverflowatline1

How to cancel Douyin account on Douyin

How to cancel Douyin account on Douyin

What are the differences between Eclipse version numbers?

What are the differences between Eclipse version numbers?