From September 19th to 23rd, 2023, the China Industry Fair will be held grandly in Shanghai

At the 7.1H E001 Card Robot booth, nearly 30 sets of exhibits were brought, covering new technologies for sensing dimensionality, new green and low-carbon applications, online VR cloud exhibition halls, etc. Among them, the JAKA Zu s collaborative robot version (JAKA Zu s) won the "CIIF Robot Award".

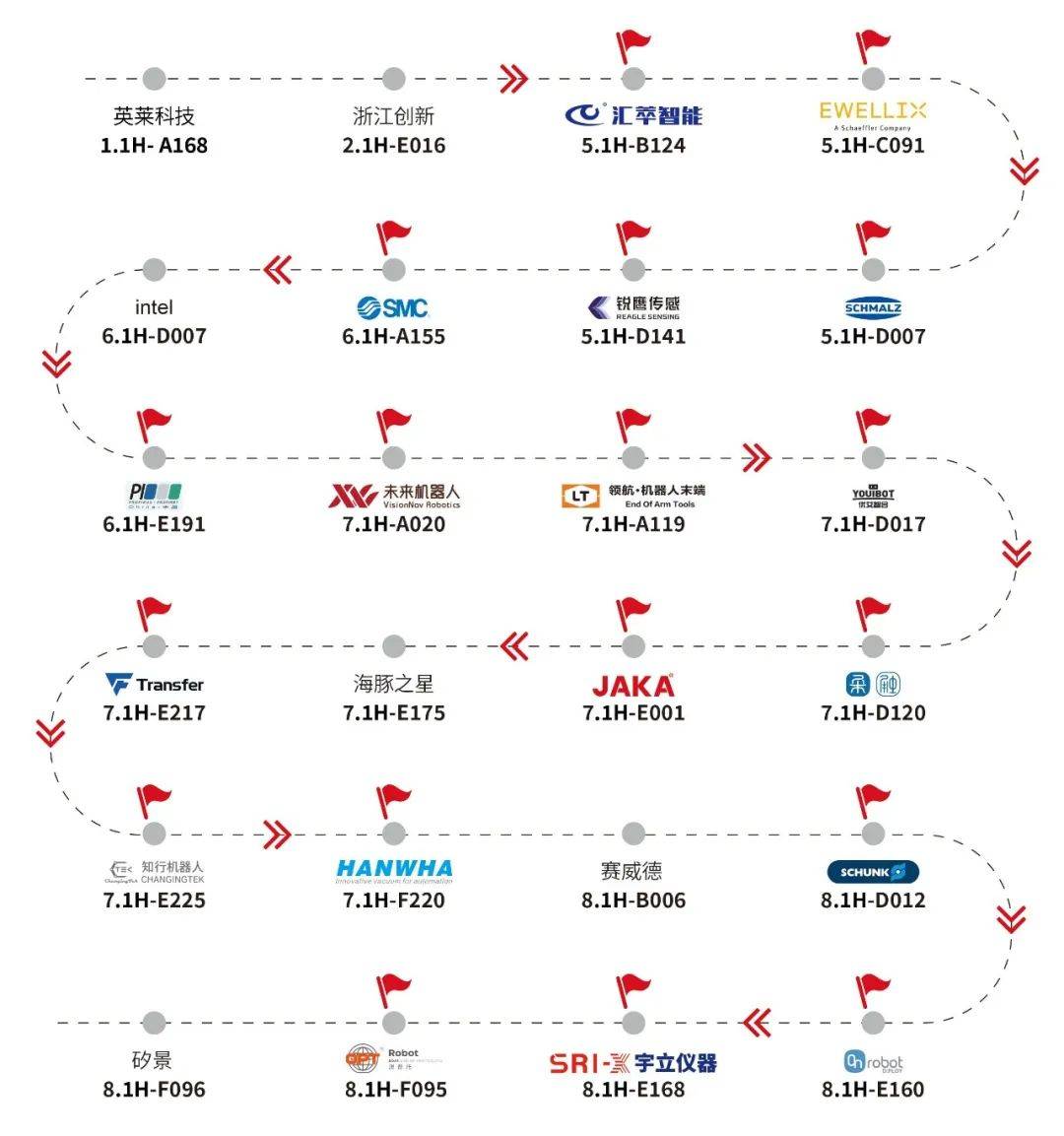

In addition, the Card Festival Robot also cooperates with global partners to carry out joint exhibition "stamp collection" activities, with fancy check-in and fun interactions, as well as gift giving, focusing on the three dimensions of "show, talk and play" , presented an informative, interesting and innovative exhibition to the audience, and also released the "2023 Collaborative Robot Industrial Case White Paper".

New 2.5D visual positioning technology

At the JAKA Robot booth, many JAKA new technological breakthroughs and hard-core information are worthy of the attention of professional audiences. The Robot Lecture Hall noticed that the JAKA 2.5D visual display platform is a new technology carrier that is both cutting-edge and practical.

Currently, more and more people are paying attention to composite robots, which are a new form of expanding application scenarios

A composite robot with both "hands and feet" is formed by integrating a collaborative robot and a mobile chassis. When performing operations such as multi-station high-precision loading and unloading, the robot is often required to flexibly adjust its spatial posture and intelligently perform high-precision operations. This puts forward higher requirements for the overall spatial positioning accuracy of the composite robot.

Most mobile chassis on the market use SLAM technology, which can achieve centimeter-level positioning accuracy. The accuracy of collaborative robots is usually at the millimeter level, but when they are combined together, they can only achieve centimeter-level positioning accuracy

Rewritten content: This means that when performing positioning assembly, screw tightening and other operations, the camera needs to be used for more precise positioning. If you use a 2D camera, you need to ensure that the optical axis is perpendicular to the working plane, but it cannot perform stereoscopic space pose correction well, so manual plane calibration is required during the deployment stage. If you use a 3D camera, the cost is too high

Based on this, the self-developed 2.5D visual positioning technology of Jieka Robot just fills the gap in this part of the scene demand.

Jieka robot adopts a new self-developed 2.5D positioning technology, and achieves dynamic estimation of spatial pose and high-precision positioning by empowering the 2D camera to sense dimensionality. This makes the robot more efficient and convenient in positioning operations, while reducing manual workload

For composite robots, the Lens 2D camera integrated with 2.5D positioning technology can calculate the spatial pose of the workpiece through label code positioning. It can assemble with a shaft hole gap of 0.5mm. Make the mobile operation of composite robots more intelligent and precise.

It is worth mentioning that in the precise positioning mode, the camera can achieve an accuracy of 0.2mm. For the assembly of shaft holes with a gap less than 0.2mm, the robot can also integrate force control sensing technology. During the assembly process of the vision-guided robot, further improves the working accuracy of the composite robot to ±0.05mm.

This camera improves the scene value of collaborative robots and even composite robots to a certain extent, making the card-saving composite robot capable of more scene applications.

For example, in a substation, high-voltage switch inspection is an important task. Since this scene is dangerous, using a composite robot to replace humans for inspection is a good solution, but if the composite robot cannot operate properly, Precision can lead to serious safety issues.

Using cameras integrated with 2.5D positioning technology for compensation undoubtedly provides customers with a more excellent and easy-to-deploy technical solution. In operations such as multi-station CNC loading and unloading, adding 2.5D vision can also make composite robots more comfortable, comprehensively broaden the application scope, and empower enterprises to implement cost reduction and efficiency improvement.

▍Open application possibilities in emerging scenarios

In some new application scenarios, the card-saving robot is not only that, but also conducts more diversified exploration and practice through its own products

With its small size, flexibility, simplicity and ease of use, rapid deployment, and support for human-machine collaboration, the card-saving robot has quickly been integrated into new energy vehicle manufacturing, agriculture, services and other industries, becoming an important tool to empower the industry

For example, for many application scenarios in the current hot new energy industry chain, Card Saving Robot has created a variety of flexible solutions and has been implemented by well-known domestic and foreign companies.

What is displayed at the festival booth is a very typical collaborative robot charging application.

Major new energy vehicle companies are currently actively promoting the "last mile" of convenient charging, and new energy vehicle charging facilities are continuously developing in the direction of automation, networking, and intelligence

Card Saving Robot found that in the application of automatic charging of new energy vehicles, collaborative robots can be used to perform the charging process of automatic plugging and unplugging of electric vehicles. If this process is broken down, the rotating mechanism mainly drives the charging base to randomly adjust a position, which puts forward requirements for the positioning and path planning capabilities of the collaborative robot.

Therefore, the card-saving robot uses a 3D camera to take pictures to locate the position of the charging base, and uses its "hands and eyes" to accurately identify the planned path, so that it can carry the charging head and automatically insert it into the charging base to simulate charging.

allows users to park at any angle, providing end users with an intelligent vehicle charging experience and helping companies build high-quality operational services.

In addition,Jieka also has some innovative exploration attempts in the agricultural field.

Facing the development concept of smart agriculture, at this exhibition, Jieka Robot demonstrated a composite robot integrated with AGV. This composite robot can not only realize SLAM map construction, automatic navigation and obstacle avoidance, but also realize "watering flowers" this special process.The main purpose behind this is to use the action trajectory setting function of the

Jieka robot to control the height and range of water spraying. ensures the frequency of watering within the effective range, and can complete the maintenance work of green plants, fruits and vegetables regularly and quantitatively. .

Prior to this, Professor Xie Fei’s team at Nanjing Normal University designed a lightweight multi-position mobile gripper based on deep learning and hand-eye integration based on the JAKA MiniCobo collaborative robot, AGV mobile platform, flexible gripping end tools and other components. The picking robot can not only complete the picking operations of various types, shapes and sizes of fruits and vegetables, but also complete autonomous navigation and positioning, realizing efficient and intelligent picking and grabbing of tomatoes, oranges and other fruits and vegetables by robots. This project won the first prize for the national finals team in the 16th China Graduate Electronic Design Competition.

Nowadays, Card-Saving Robot is using

safe, easy-to-use, flexible and intelligent, low-carbon and energy-saving collaborative robot products to comprehensively help enterprises make long-term layouts and promote the continuous optimization and innovation of global emerging industrial chains. develop. We noticed that the green and low-carbon digital display area of this special exhibition of Jika Robot combines the JAKA OTA smart service platform and the JAKA energy-saving signboard to monitor the operating status and power consumption of the robot in real time.

Not only It allows users to manage robot health in the cloud, and visualizes the energy-saving and carbon-reduction results of card-saving robots,empowering the construction of green smart factories.

Online participation is also an eye-catching part of the exhibition areas of many robot companies in this industry expo.

This JAKA Panoramic Industry Expo showcases nearly 30 sets of robot applications. For ordinary audiences, they can not only visit the exhibition offline, but also experience the JAKA Panoramic Industry Expo through virtual reality, live broadcast and other methods. meeting

In terms of comprehensive exhibits,

As a leading enterprise in the world of collaborative robots, Jieka Robot’s exhibits are very comprehensive and representative.From a single workstation to a flexible production line, from a fixed workstation to a mobile workstation, from action execution to intelligent protection and management, it can be said that card-saving robots are providing all-round, multi-level, and three-dimensional intelligent manufacturing solutions. Accelerate the flexible and intelligent evolution of new industries

For example

For example

the card-saving robot's solutions cover smart industry (automotive, electronics, general industry), education, new business formats, etc.

In terms of hardware,Jieka Robot’s products can integrate perception, execution, and mobile devices from internationally renowned brands.

In terms of software, the card-saving robot not only demonstrated JAKA’s self-developed 2.5D positioning technology, palletizing process package, welding process package, JAKA OTA smart service platform, etc., but also demonstrated the The result of cooperation with Siemens. It is understood that the card-saving robot has opened up communication with Siemens SRL library , and can directly control the robot through Siemens Botu system programming, achieving convenient and efficient industrial scene deployment and easier docking The original production line and process flow significantly reduce the customer's integration costs. At the CIIE, users can watch robots dancing, watering flowers, playing Rubik's Cube, experience robot photography, coffee latte art, and participate in interesting interactive competitions of human-machine collaboration at the Jieka Robot booth. There are also many check-in games. Cool gifts are constantly being given away, and the Jieka Robot booth has become the traffic star of this CIIF. At the same time, the Jieka Robot also used VR technology to extend the booth to the company’s internal exhibition hall. By wearing VR glasses at the scene, the audience can "cross space", "visit" JAKA headquarters in person, and visit the company's internal exhibition hall for more applications. We also noticed that in many different exhibition halls of the CIIF, you can also see a touch of red of the Jieka Robot. This is a joint exhibition of the Jieka Robot and many global partners of "Moments", This time, visitors can also participate in the Festival Card Robot Joint Exhibition and Philatelic Activity to obtain exquisite peripheral gifts from various brands. ▍"2023 Collaborative Robot Industrial Case White Paper" released After three years, the China Industry Fair returns grandly. In the past three years, the collaborative robot industry and its upstream and downstream have undergone tremendous changes, which has also brought more opportunities and challenges Faced with the rapidly developing market, what is the development trend of collaborative robot technology? What kind of products can help customers gain long-term competitive advantage? What actual projects are representative of the industry? As an industry benchmark, Jieka Robot has its own unique understanding. On September 20, the card-saving robot will be displayed at Shanghai Jiao Tong University Yuanzhi Robot Research Institute, Shanghai Artificial Intelligence Industry Association, Shanghai Auto Parts Industry Association, Shanghai Robot Industry Technology Research Institute Co., Ltd., Beijing Platinum Witnessed by Jia Information Services Co., Ltd., Shanghai Qianyu Intelligent Technology Co., Ltd. and many other industry organizations, scientific research institutes, and partners, the "2023 Collaborative Robot Industrial Case White Paper" was released to provide high-value solutions to the industry with real implementation cases. Experience, promote the co-construction, co-creation and common development of the industrial chain, and accelerate the upgrading of global industrial flexible automation. Jieka Robot is also the supporting unit of the 2023 Shanghai "Zhangjiang Robot Valley Cup" robot competition, and will also provide technology, equipment and resource support for the competition. The competition launching ceremony will be held at the JAKA booth The 2023 China Industry Fair will last until September 23. We look forward to your visit to Jieka Robot at booth 7.1H E001

The above is the detailed content of New product unveiled: A robot can water flowers and charge cars. For more information, please follow other related articles on the PHP Chinese website!

What should I do if my iPad cannot be charged?

What should I do if my iPad cannot be charged?

Solution to reboot and select proper boot device

Solution to reboot and select proper boot device

What should I do if the ps temporary disk is full?

What should I do if the ps temporary disk is full?

Activate qq number

Activate qq number

How to jump with parameters in vue.js

How to jump with parameters in vue.js

What protocols does the ssl protocol include?

What protocols does the ssl protocol include?

How to open Windows 7 Explorer

How to open Windows 7 Explorer

Solution to invalid signature

Solution to invalid signature