How do young people fall in love with and take root in a city when they come to it?

Because here, we can chase our dreams and have unlimited possibilities

Baoshan young entrepreneur-Hu Yuchen, co-founder and chief problem officer of Shanghai Dajie Robot Technology Co., Ltd., is one of the innovative entrepreneurs in Shanghai.

The pursuit of technology research and development and product innovation is very important

is the original intention of starting a business

He was born in 1992, and his entrepreneurial journey began in 2017. Together with two other post-85s friends with digital construction backgrounds, he developed a robot digital twin system and started the business in a 100-square-meter garage. The idea was to have robots build houses. Hu Yuchen said at Shanghai Dajie Baoshan Laboratory

At present, Shanghai Dajie Robot Technology Co., Ltd. has become China's leading intelligent robot system company, providing advanced flexible production solutions in the construction and industrial fields

In Hu Yuchen’s view, how to keep himself and his employees committed to technology research and development and product innovation is a difficult task that requires constantly stepping out of the comfort zone. However, he will always try to find some simpler application scenarios to implement product implementation. Help everyone solve problems.

"When the company's first-generation industrial software product project was established, I told all my friends that this product would definitely be overturned by me in the future." Hu Yuchen said that the process of innovative research and development is the process of facing the unknown.

Hu Yuchen said: "The English name of our company, Robotic plus.AI, means 'empowering buildings with machines and AI'. The Chinese name 'Dajie' means 'seeing the vastness of intelligent manufacturing through robots'" world'."

Intelligent robots are the core equipment for the development of the intelligent terminal industry. They are also the forefront of the integration of advanced manufacturing and new generation information technology. They are also an important area of global technological competition and industrial upgrading

The Ministry of Industry and Information Technology and the 15th Five-Year Plan jointly released the national "14th Five-Year Plan for Robot Industry Development", proposing to vigorously promote the supply of high-end products and increase the breadth and depth of applications. Shanghai issued the "Shanghai Action Plan to Promote High-Quality Intelligent Terminal Industry (2022-2025)", which clearly stated that during the "14th Five-Year Plan" period, it will focus on developing the intelligent terminal industry represented by robots and create a number of benchmark brands. and application scenarios

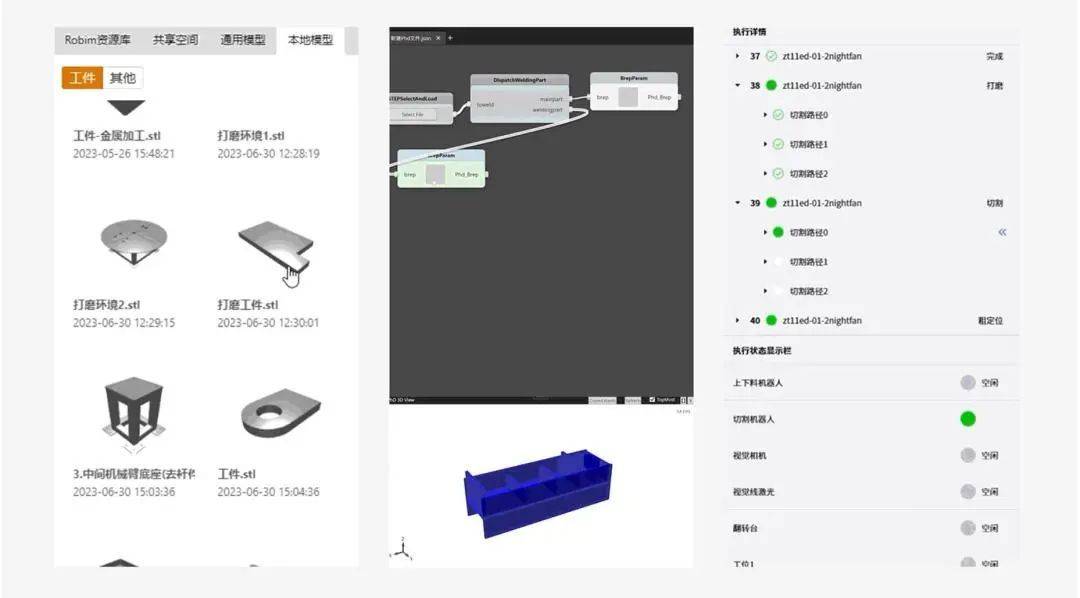

On July 8, 2023, Dajie Robot released a new AI product-RoBIM Cloud at the World Artificial Intelligence Conference (WAIC). After 3 years of research and development, RoBIM Cloud is a cloud-native intelligent robot flexible production platform designed to help manufacturing practitioners quickly build and deploy executable production robot solutions

In Hu Yuchen’s view, after years of scenario practice in the construction, shipbuilding, engineering machinery and energy industries, Dajie has gradually formed a cross-industry “algorithmic data process” model service capability, which has been accumulated and precipitated into the RoBIM Cloud platform product. "With the help of Big Model and AIGC, Dajie hopes to work with customers and partners from various industries through RoBIM Cloud to jointly create a powerful robot AI assistant."

RoBIM Cloud has three core technology bases: algorithm, data and process.

Based on geometric algorithms and numerical optimization methods, combined with AI technology, we have successfully established a modular low-code geometric algorithm library and a CAPP algorithm library for process characteristics. We have brought together industry expertise and continuous accumulation of technology to provide users with a programming-free robotic flexible production cloud platform, enabling one-click import and immediate production of massive drawings and models. With the help of the capabilities of industrial software RoBIM, we have launched intelligent welding and cutting products to provide support for intelligent manufacturing of high-end equipment in the industrial field. We have already won a number of industry-leading customers. Our products are widely used in the blanking and production workshops of customers in construction steel structures, bridges, coal machinery, shipbuilding, engineering machinery, offshore engineering and other industries. Our related series of products have been selected as benchmark enterprises and application scenarios of intelligent robots in Shanghai, and have been recognized by Guangdong Province as a typical example of innovative services for new technologies and new products in intelligent construction. Our intelligent cutting center RobimCut only takes 2 minutes from batch import of workpieces to robot production, and can quickly complete the precise positioning of workpieces in only 15 seconds. Compared with traditional line laser scanning, it improves efficiency by 150-200%. ;The production volume of typical parts beveling has been increased from 80 pieces per person per day to 240 pieces per machine per day, which has increased the overall efficiency by nearly 3 times

RobimCut intelligent cutting center.

RobimWeld intelligent welding center can be applied to steel assembly workpieces in the fields of construction, bridges and offshore steel structures. Through RobimWeld software, you can directly and quickly read various types of drawings and model original data such as ifc, dxf, stl, stp, etc., and automatically generate welds, welding processes and robot welding paths. This helps companies reduce the time for making processing drawings by 90%, save 80% of manual programming time and 2-3 programmers. At the same time, its stand-alone efficiency is about 1.8 times that of traditional manual welding

Dajie cooperated with Aluminum Youjia, the global leader in prefabricated composite buildings, and took advantage of the prefabricated steel structure building market in the Guangdong-Hong Kong-Macao Greater Bay Area to design a set of welding production lines that are efficient, flexible and adaptable to flexible production. This production line is the first of its kind in the industry. Through the implementation and practice of the project, it has taken a solid step for the prefabricated modular integrated construction industry and moved towards the direction of intelligent construction in emerging industries

Dajie modular integrated construction welding production line.

This project applies the flexible production system currently developed by Dajie for the steel structure MIC industry. By introducing automated welding robots, flexible tooling, laser visual recognition systems and RobimWeld software, it can greatly improve production efficiency and quality consistency. At the same time, it is compatible with workpieces with a length of 4-12m, a width of about 3-3.5m, and a thickness of 0.1-0.2m, and is compatible with different MIC product specifications to the maximum extent. It can meet the future production needs of various products including transitional housing, simple public housing, data centers, student apartments, etc.

Good business environment, rich application scenarios

Choose in Baoshan

Hu Yuchen said that the reason for choosing Shanghai and Baoshan was because Shanghai has a good industrial environment, especially for the industry where he chose to start a business. "For an industry such as flexible production, which involves end users, robot-related supply chains, and the underlying technology development of some core industrial software, the city of Shanghai happens to have the above-mentioned advantages. At the same time, it is easier to attract people in Shanghai To attract outstanding talents from all over the world to join our business is the core reason why we have been determined to develop in Shanghai.”

In 2021, Dajie Robotics will settle in Baoshan. Combining the regional advantages of Baoshan's robotics and steel structure industries to form industrial linkage is a strategic move for enterprises to accelerate R&D implementation. "Good business environment, high-quality talent team, convenient financing conditions, rich application scenarios... Dajie has also truly felt the encouragement, recognition and support of governments at all levels for the 'smart construction' industry and Dajie. ”

In the future, Dajie Robot will be based on the core industrial software RoBIM, deeply integrate the process experience of construction steel structure, shipbuilding, engineering machinery, coal machinery and other industries, and deeply explore intelligent methods such as geometric algorithms, process generation, robot free planning, and 3D vision. , breaking through technical bottlenecks such as traditional teaching, offline programming, and parametric programming, and continuously empowering the industry's intelligent transformation, lean production, and digital transformation. Hu Yuchen is moving forward steadily on the road of innovation, one step at a time

Source: Shanghai Baoshan official WeChat

The above is the detailed content of Baoshan's innovative young entrepreneurs use robots to open up unlimited possibilities for smart manufacturing. For more information, please follow other related articles on the PHP Chinese website!