Technology peripherals

Technology peripherals

AI

AI

AI+ welding, the Heimo robot at the Industrial Expo 'has many skills but not too much'

AI+ welding, the Heimo robot at the Industrial Expo 'has many skills but not too much'

AI+ welding, the Heimo robot at the Industrial Expo 'has many skills but not too much'

Industrial Fair >>

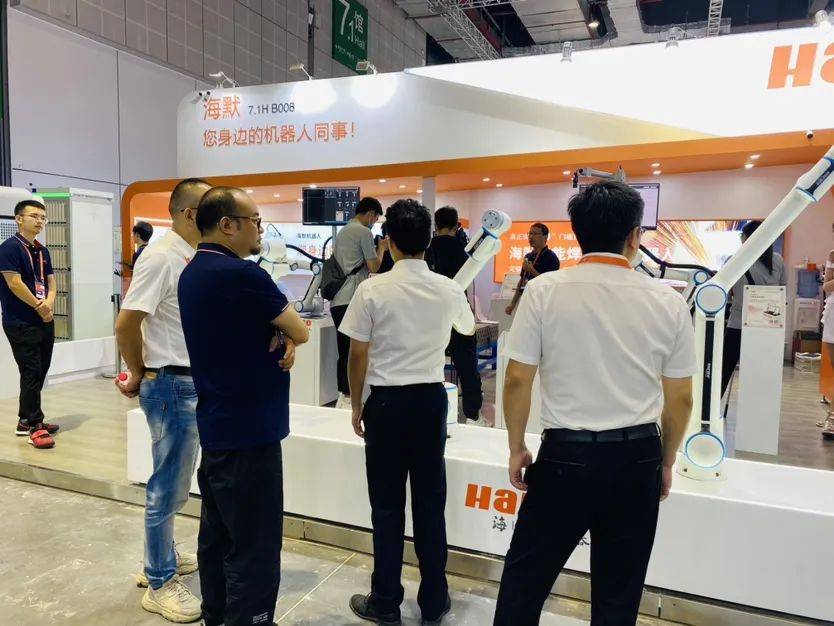

The 23rd China International Industrial Fair has concluded successfully recently. As one of the largest, most comprehensive, most high-level and most influential exhibitions in China’s industrial field, it has attracted many industrial manufacturing companies to participate in the exhibition. Haimo The robot also showed its "special skills" at this exhibition - made a wonderful appearance with an intelligent welding collaborative robot, demonstrating the latest welding processes, technologies and applications. Robot Online, as the strategic cooperative media of the CIIF, also conducted on-site highlight tracking and reporting on Heimer Robot. Let’s review the wonderful performance of Heimer Robot!

Robot online live broadcast report:

01 Intelligent welding collaborative robot

(Heimer Robot Family)

The robot colleague around you!

Based on the HM series of collaborative robots independently developed by Haimo, it has the characteristics of large load and large arm span. It can easily achieve an overweight load of 25KG and a working radius of up to 900mm~1508mm. It can be widely used in welding and machine tool loading and unloading. , spraying, palletizing, assembly and large load handling and other application scenarios.

Haimer HM series collaborative robots integrate high-precision force control, machine vision and AI technology to adapt to uncertain working environments. With extremely high flexibility, accuracy and safety, can greatly enhance the flexibility in the production process and improve productivity.

02Multiple welding applications

01 Precise drag and drop teaching

The intelligent universal welding robot developed, designed, produced and manufactured by Haimo Robot can effectively solve the difficulty of operating welding equipment, can complete the welding trajectory through simple drag and drop teaching Set up and perform welding operations.

02 Fuzzy position finding

Haimo intelligent welding collaborative robot is equipped with a welding seam tracking system. It can confirm the starting point and end point of the welding seam through fuzzy dragging, and uses high-order functions to automatically fit and generate welding trajectories. It can realize straight lines, curved surfaces, irregular surfaces, etc. Weld fitting of arbitrary shapes.

The content that needs to be rewritten is: 032D visual flexible welding

2D visual intelligent flexible welding workstation uses 2D visual recognition technology to realize online identification and positioning of weld seams, and automatic planning of robot welding trajectories. No need for teaching and programming, is suitable for flat flexible welding of multiple varieties and small batches of non-standard parts, and can be used in laser welding, arc welding and other application scenarios.

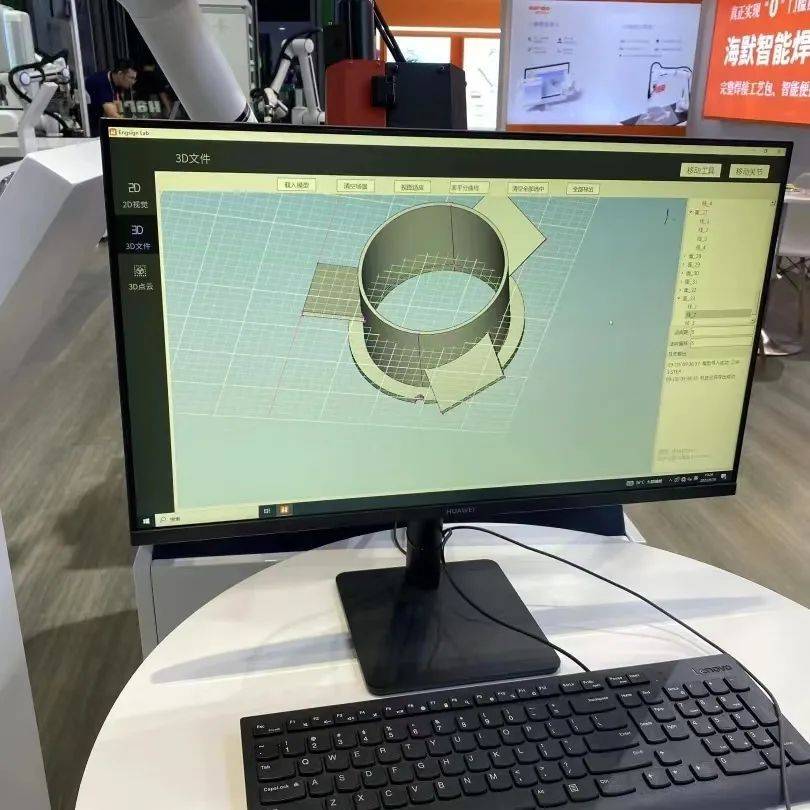

The content that needs to be rewritten is: 043D Vision AI Welding

Equipped with a 3D camera to scan the welded components as a whole, obtain the point cloud data of the workpiece in real time and generate a three-dimensional point cloud model; by processing and analyzing the point cloud, the weld parameter information of the workpiece to be welded (such as the weld seam) is automatically extracted position, welding leg size, etc.);Through the processing of welding seam parameter information, teaching-free programming and automatic welding work are realized, and the transformation from welding automation to intelligence is truly realized.

The content that needs to be rewritten is: 05 Import 3D model

Import the three-dimensional model of the workpiece to be welded, Engsign Lab automatically extracts welding seam information, plans the welding trajectory, and realizes teaching-free programming, truly realizes the transformation from welding automation to intelligence.

06 File Management Robot

In addition, Haimo also demonstrated the application of file management robots on site, realizing the automatic access, identification, inspection and transmission of physical files by intelligent robots; realizing the separation of people and physical files, and improving the quality of files Confidentiality, security. Through the AGV car body, six-axis robotic arm, terminal file access mechanism, automatic file caching system path planning system and visual positioning system, combined with RFID real-time monitoring of inventory intelligent file cabinets, automatic storage of physical files in the file room is realized Retrieval and transmission work, thereby ensuring the safety, timeliness and accuracy of query files, and realizing unmanned and intelligent management of files.

The future is bright

As China's leading collaborative robot manufacturer, Haimo Robot adheres to the corporate philosophy of "becoming a robot colleague by your side". We are always user-centered and provide customers with a full range of collaborative robot solutions through continuously innovative technologies and products. We look forward to more innovative and easy-to-use product solutions from Heimer Robots in the future!

Original statement: Please indicate the source when reprinting this article,

Disclaimer: Some pictures in this article come from the Internet

If you find any infringement, please contact us immediately to make relevant corrections

The above is the detailed content of AI+ welding, the Heimo robot at the Industrial Expo 'has many skills but not too much'. For more information, please follow other related articles on the PHP Chinese website!

Hot AI Tools

Undresser.AI Undress

AI-powered app for creating realistic nude photos

AI Clothes Remover

Online AI tool for removing clothes from photos.

Undress AI Tool

Undress images for free

Clothoff.io

AI clothes remover

AI Hentai Generator

Generate AI Hentai for free.

Hot Article

Hot Tools

Notepad++7.3.1

Easy-to-use and free code editor

SublimeText3 Chinese version

Chinese version, very easy to use

Zend Studio 13.0.1

Powerful PHP integrated development environment

Dreamweaver CS6

Visual web development tools

SublimeText3 Mac version

God-level code editing software (SublimeText3)

Hot Topics

1378

1378

52

52

I Tried Vibe Coding with Cursor AI and It's Amazing!

Mar 20, 2025 pm 03:34 PM

I Tried Vibe Coding with Cursor AI and It's Amazing!

Mar 20, 2025 pm 03:34 PM

Vibe coding is reshaping the world of software development by letting us create applications using natural language instead of endless lines of code. Inspired by visionaries like Andrej Karpathy, this innovative approach lets dev

Top 5 GenAI Launches of February 2025: GPT-4.5, Grok-3 & More!

Mar 22, 2025 am 10:58 AM

Top 5 GenAI Launches of February 2025: GPT-4.5, Grok-3 & More!

Mar 22, 2025 am 10:58 AM

February 2025 has been yet another game-changing month for generative AI, bringing us some of the most anticipated model upgrades and groundbreaking new features. From xAI’s Grok 3 and Anthropic’s Claude 3.7 Sonnet, to OpenAI’s G

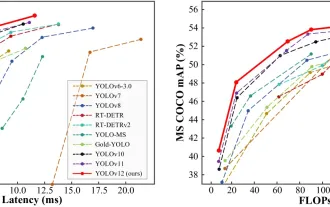

How to Use YOLO v12 for Object Detection?

Mar 22, 2025 am 11:07 AM

How to Use YOLO v12 for Object Detection?

Mar 22, 2025 am 11:07 AM

YOLO (You Only Look Once) has been a leading real-time object detection framework, with each iteration improving upon the previous versions. The latest version YOLO v12 introduces advancements that significantly enhance accuracy

Is ChatGPT 4 O available?

Mar 28, 2025 pm 05:29 PM

Is ChatGPT 4 O available?

Mar 28, 2025 pm 05:29 PM

ChatGPT 4 is currently available and widely used, demonstrating significant improvements in understanding context and generating coherent responses compared to its predecessors like ChatGPT 3.5. Future developments may include more personalized interactions and real-time data processing capabilities, further enhancing its potential for various applications.

Best AI Art Generators (Free & Paid) for Creative Projects

Apr 02, 2025 pm 06:10 PM

Best AI Art Generators (Free & Paid) for Creative Projects

Apr 02, 2025 pm 06:10 PM

The article reviews top AI art generators, discussing their features, suitability for creative projects, and value. It highlights Midjourney as the best value for professionals and recommends DALL-E 2 for high-quality, customizable art.

o1 vs GPT-4o: Is OpenAI's New Model Better Than GPT-4o?

Mar 16, 2025 am 11:47 AM

o1 vs GPT-4o: Is OpenAI's New Model Better Than GPT-4o?

Mar 16, 2025 am 11:47 AM

OpenAI's o1: A 12-Day Gift Spree Begins with Their Most Powerful Model Yet December's arrival brings a global slowdown, snowflakes in some parts of the world, but OpenAI is just getting started. Sam Altman and his team are launching a 12-day gift ex

Google's GenCast: Weather Forecasting With GenCast Mini Demo

Mar 16, 2025 pm 01:46 PM

Google's GenCast: Weather Forecasting With GenCast Mini Demo

Mar 16, 2025 pm 01:46 PM

Google DeepMind's GenCast: A Revolutionary AI for Weather Forecasting Weather forecasting has undergone a dramatic transformation, moving from rudimentary observations to sophisticated AI-powered predictions. Google DeepMind's GenCast, a groundbreak

Which AI is better than ChatGPT?

Mar 18, 2025 pm 06:05 PM

Which AI is better than ChatGPT?

Mar 18, 2025 pm 06:05 PM

The article discusses AI models surpassing ChatGPT, like LaMDA, LLaMA, and Grok, highlighting their advantages in accuracy, understanding, and industry impact.(159 characters)