Technology peripherals

Technology peripherals

AI

AI

Han's collaborative robot won the '2023 Welding Robot Industry Chain Pioneer Award'

Han's collaborative robot won the '2023 Welding Robot Industry Chain Pioneer Award'

Han's collaborative robot won the '2023 Welding Robot Industry Chain Pioneer Award'

On October 12, the 2023 (Second) Welding Robot Technology and Application Summit was hosted by High-Tech Robot and High-Tech Robot Industry Research Institute (GGII) with the theme of "Welder Attack·Journey of the Brave" Held grandly in Shanghai, Han's Robots and more than 300 industry chain professionals gathered together to discuss the future of collaborative robots.

As an important processing technology equipment in modern industry, welding equipment is widely used in military industry, aerospace, offshore engineering, pressure vessels, pipeline engineering, petrochemical engineering, engineering machinery, power engineering, construction, steel structure, automobile manufacturing, and rail transit. , light industry and civil and other industries have a wide range of applications. Gaogong Robot believes that with the continuous breakthroughs in automated welding, intelligent welding and welding-related technologies, automated welding equipment represented by welding robots will become an inevitable trend in the future development of the industry.

With its continuous innovation in the field of collaborative welding robots, Han's Robots won the "2023 Welding Robot Industry Chain Pioneer Award - Advanced Technology Award" and became one of the key forces leading the development of collaborative welding robots.

As a pioneer in promoting the transformation from traditional manual welding to robotic automatic welding, Han's Robot has launched fixed and push-type models based on long-term practical experience and combined with the advantages of Elfin-Pro series collaborative robots such as integrated end force control and internal wiring layout. One-stop welding workstations with various forms such as cart-type and portable (equipped with magnetic base), which can be applied to various complex welding scenarios. The workstation is equipped with arc tracking and laser welding seam tracking technology, which can correct welding deviations in real time, improve welding quality, and make welding operations simpler and almost zero-threshold.

In practical applications, Han's Robot has been highly recognized by many partners and end users, and has repeatedly creatively solved the problems and troubles of customers in the transformation to robot automatic welding.

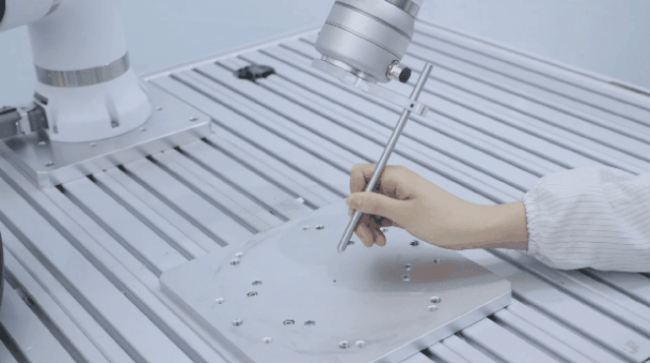

▲ Han’s Robot Keynote Speech Session

In addition, Han’s Robot’s unique advantages in core technology, product design and user experience also make “our robotic arms more suitable for welding applications”——

Robotic arm structure more suitable for welding: Compared with traditional collaborative robots, Han's robots adopt a unique double-joint module design. One motion module contains two joints, forming a unique kinematic structure, which can achieve better results during welding operations. High flexibility; the design of the end of the robot arm is simpler and more practical, and welding tasks can be quickly established through button operations; the cables required for welding configuration are all laid out through internal routing and "hidden" inside the robot arm, which can effectively avoid Due to interference from external wiring harnesses, problems such as limited movement range of the robotic arm and interference with communication signals may occur.

In addition, Han’s robot body has the advantages of high strength and high wear resistance, and can operate stably in welding operating environments with violent movements or external impacts.

Arm span design that is closer to welding needs: Elfin-Pro series collaborative robots have arm lengths ranging from 590mm to 1800mm, a maximum working range of up to 1.8m, and a joint movement range of ±360°. Multiple models are available to meet different welding needs. .

Higher precision: Using more advanced motion control algorithms, the repeat positioning accuracy can reach ±0.02mm under full load and full speed, the absolute positioning accuracy can reach ±0.2mm, and the trajectory accuracy can reach ±0.5mm.

More convenient and efficient teaching operation: Elfin-Pro supports integrated end force control, which can easily realize dragging with only a drag force within 3N; helping users to drag the welding gun to the designated position easily and quickly Target solder joints to achieve accuracy and improve work efficiency.

More open and adaptable to various types of welding equipment: Han's Robot can quickly adapt to domestic and foreign mainstream welding machines, including Megmetrochi, Aotai, Binzer, Panasonic, Funis and Idaxin, etc. At the same time, it can efficiently connect with manufacturers of robot vision and controllers that focus on the welding industry, broadening customers' product selection space.

Better environmental adaptability: Based on EtherCAT ultra-long-distance deployment, the connecting cable between the Han's robot body and the electric control box can be extended to 50m, and can be combined with a magnetic base, gantry, truss, etc. to achieve flexible movement. Suitable for welding workshops with complex production environments.

Simpler and easier-to-use welding process package: Convert the skills and practical experience of senior welders into welding process parameters. With simple settings, ordinary welders can also complete welding work with different trajectories and materials, meeting most welding application scenarios. need.

The development of collaborative welding robots to complete tasks together through human-machine collaboration can not only help enterprises promote production line automation upgrades and improve quality and efficiency, but also greatly improve the welding working environment and allow robots to do more standardization , highly repetitive, low-value work, this is Han’s Robot’s inevitable choice to fulfill its corporate mission of “serving the people with robotic technology”.

We hope to work hand in hand with domestic and foreign robot vision and controller manufacturers, welding industry customers, integrators and other partners to jointly promote the intelligent upgrading and transformation of the welding industry.

The above is the detailed content of Han's collaborative robot won the '2023 Welding Robot Industry Chain Pioneer Award'. For more information, please follow other related articles on the PHP Chinese website!

Hot AI Tools

Undresser.AI Undress

AI-powered app for creating realistic nude photos

AI Clothes Remover

Online AI tool for removing clothes from photos.

Undress AI Tool

Undress images for free

Clothoff.io

AI clothes remover

AI Hentai Generator

Generate AI Hentai for free.

Hot Article

Hot Tools

Notepad++7.3.1

Easy-to-use and free code editor

SublimeText3 Chinese version

Chinese version, very easy to use

Zend Studio 13.0.1

Powerful PHP integrated development environment

Dreamweaver CS6

Visual web development tools

SublimeText3 Mac version

God-level code editing software (SublimeText3)

Hot Topics

1378

1378

52

52

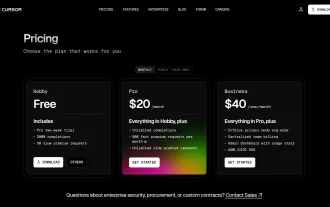

I Tried Vibe Coding with Cursor AI and It's Amazing!

Mar 20, 2025 pm 03:34 PM

I Tried Vibe Coding with Cursor AI and It's Amazing!

Mar 20, 2025 pm 03:34 PM

Vibe coding is reshaping the world of software development by letting us create applications using natural language instead of endless lines of code. Inspired by visionaries like Andrej Karpathy, this innovative approach lets dev

Top 5 GenAI Launches of February 2025: GPT-4.5, Grok-3 & More!

Mar 22, 2025 am 10:58 AM

Top 5 GenAI Launches of February 2025: GPT-4.5, Grok-3 & More!

Mar 22, 2025 am 10:58 AM

February 2025 has been yet another game-changing month for generative AI, bringing us some of the most anticipated model upgrades and groundbreaking new features. From xAI’s Grok 3 and Anthropic’s Claude 3.7 Sonnet, to OpenAI’s G

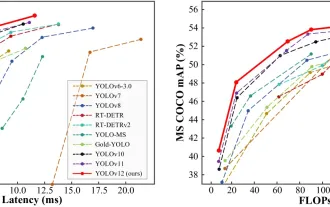

How to Use YOLO v12 for Object Detection?

Mar 22, 2025 am 11:07 AM

How to Use YOLO v12 for Object Detection?

Mar 22, 2025 am 11:07 AM

YOLO (You Only Look Once) has been a leading real-time object detection framework, with each iteration improving upon the previous versions. The latest version YOLO v12 introduces advancements that significantly enhance accuracy

Is ChatGPT 4 O available?

Mar 28, 2025 pm 05:29 PM

Is ChatGPT 4 O available?

Mar 28, 2025 pm 05:29 PM

ChatGPT 4 is currently available and widely used, demonstrating significant improvements in understanding context and generating coherent responses compared to its predecessors like ChatGPT 3.5. Future developments may include more personalized interactions and real-time data processing capabilities, further enhancing its potential for various applications.

Best AI Art Generators (Free & Paid) for Creative Projects

Apr 02, 2025 pm 06:10 PM

Best AI Art Generators (Free & Paid) for Creative Projects

Apr 02, 2025 pm 06:10 PM

The article reviews top AI art generators, discussing their features, suitability for creative projects, and value. It highlights Midjourney as the best value for professionals and recommends DALL-E 2 for high-quality, customizable art.

o1 vs GPT-4o: Is OpenAI's New Model Better Than GPT-4o?

Mar 16, 2025 am 11:47 AM

o1 vs GPT-4o: Is OpenAI's New Model Better Than GPT-4o?

Mar 16, 2025 am 11:47 AM

OpenAI's o1: A 12-Day Gift Spree Begins with Their Most Powerful Model Yet December's arrival brings a global slowdown, snowflakes in some parts of the world, but OpenAI is just getting started. Sam Altman and his team are launching a 12-day gift ex

Google's GenCast: Weather Forecasting With GenCast Mini Demo

Mar 16, 2025 pm 01:46 PM

Google's GenCast: Weather Forecasting With GenCast Mini Demo

Mar 16, 2025 pm 01:46 PM

Google DeepMind's GenCast: A Revolutionary AI for Weather Forecasting Weather forecasting has undergone a dramatic transformation, moving from rudimentary observations to sophisticated AI-powered predictions. Google DeepMind's GenCast, a groundbreak

Which AI is better than ChatGPT?

Mar 18, 2025 pm 06:05 PM

Which AI is better than ChatGPT?

Mar 18, 2025 pm 06:05 PM

The article discusses AI models surpassing ChatGPT, like LaMDA, LLaMA, and Grok, highlighting their advantages in accuracy, understanding, and industry impact.(159 characters)