Technology peripherals

Technology peripherals

AI

AI

Passive 'force' stickers redefine precise measurement-IOTE Internet of Things Exhibition

Passive 'force' stickers redefine precise measurement-IOTE Internet of Things Exhibition

Passive 'force' stickers redefine precise measurement-IOTE Internet of Things Exhibition

Measuring the force exerted between objects is a complex process. Although it sounds simple, it is not easy in practice. Any two objects in contact will exert some force on each other, which may be due to gravity or mechanical contact, such as the weight of the object on the platform or the contact of two bones at the human knee joint.

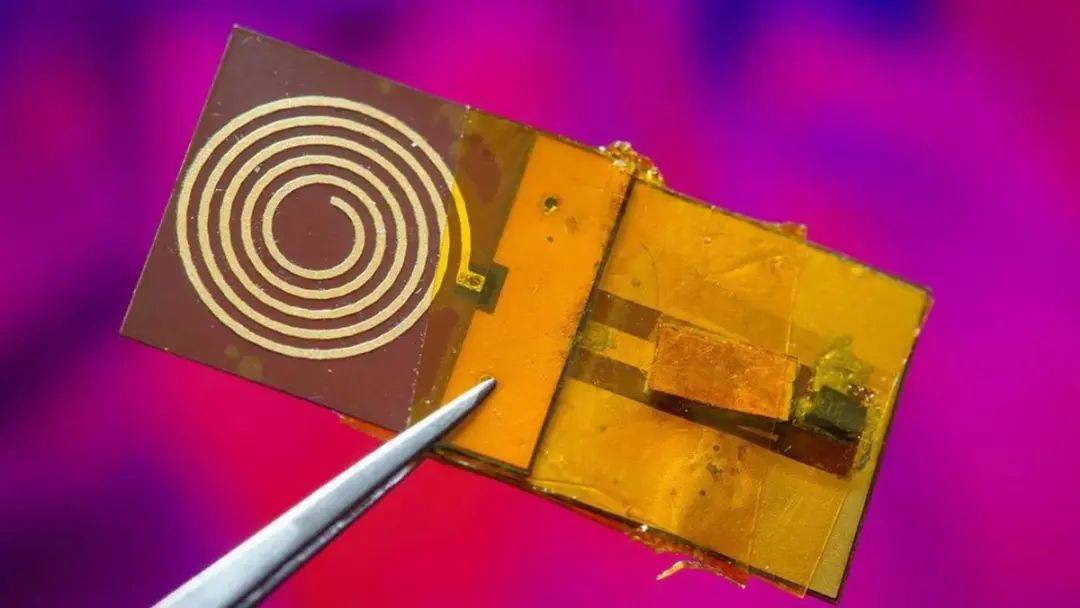

In order to measure this force more efficiently and conveniently, a research team at the University of California, San Diego developed an electronic "sticker" to assist in measuring these phenomena.

These Power Stickers are cordless, require no batteries, and can fit into small spaces, making them suitable for a variety of applications in a variety of industries. According to engineers, the device could be used in knee implants to quantitatively measure the pressure exerted by the implant on the joint. Monitoring changes in these forces is critical to assess implant fit and wear.

Dinesh Bharadia, a professor at the University of California, San Diego School of Engineering, said in a statement from the school: "Human beings are born with an inherent ability to sense force. This gives us the ability to interact seamlessly with our surroundings and also allows clinicians to conduct fine-grained surgical procedures. Introducing this ability to sense force into electronic devices and medical implants could revolutionize many industries."

These power stickers consist of two main parts. The first is a small capacitor a few millimeters thick and about the size of a grain of rice. Another component is a radio-frequency identification (RFID) sticker, which is similar to a barcode and can be read wirelessly via radio waves. The researchers used an innovative method to connect the two components, which measure the force on the object and wirelessly transmit this information to an RFID reader.

A capacitor is created by placing a thin sheet of flexible polymer between two conductive copper strips. When an external force acts on the polymer, it compresses, causing the copper strips to move closer together, increasing the charge within the capacitor.

The researchers pointed out that the increase in charge due to the applied force is important in changing the signal generated by the RFID tag. An RFID reader remotely monitors these changes and converts them into corresponding force values. This method of modifying RFID signals allows components within the force sticker to be made very small, reducing their size by a factor of a thousand compared to previous methods used to modify RFID signals.

At the same time, RFID stickers transmit radio signals through a mechanism called backscatter and consume very low power. It receives the radio signal from the RFID reader, changes the signal through the charge change caused by the capacitor, and then returns the changed signal to the reader, which parses it and converts it into the corresponding power numerical value. Therefore, the power consumption of this power sticker is very low.

Another design aspect is that the capacitors can be customized for different force ranges. By changing the soft or stiff polymer layers, the capacitor can be tuned to monitor pressures in different ranges.

In the study, researchers created and tested two types of strength stickers to verify their feasibility. A force sticker whose capacitor is made from an extremely soft polymer is used to monitor tiny forces and is suitable for use in studies that simulate knee joints. When the force sticker was placed into a joint and the researchers applied pressure, it was able to accurately detect different forces. A second force sticker with a stiffer polymer capacitor was experimentally evaluated in the field of warehouse packaging. It is taped to the bottom of the box and allows for an accurate assessment of the weight of various items placed inside the box.

According to the team, in testing, these power stickers performed very strongly. They are capable of resisting the application of force more than 10,000 times while maintaining accuracy. Additionally, according to the researchers, they can be produced at a very low cost, costing less than $2 per sticker.

However, this technology also has its limitations. Scientists point out that these force stickers can only work well in static environments and are not suitable for highly dynamic situations.

Agrim Gupta, a doctoral student in electrical and computer engineering and study co-author, said: "If we can commercialize this technology, it is conceivable that in the future these stickers can be sold as cheaply as Band-Aids."

Details of this study have been published in ACM.

The above is the detailed content of Passive 'force' stickers redefine precise measurement-IOTE Internet of Things Exhibition. For more information, please follow other related articles on the PHP Chinese website!

Hot AI Tools

Undresser.AI Undress

AI-powered app for creating realistic nude photos

AI Clothes Remover

Online AI tool for removing clothes from photos.

Undress AI Tool

Undress images for free

Clothoff.io

AI clothes remover

Video Face Swap

Swap faces in any video effortlessly with our completely free AI face swap tool!

Hot Article

Hot Tools

Notepad++7.3.1

Easy-to-use and free code editor

SublimeText3 Chinese version

Chinese version, very easy to use

Zend Studio 13.0.1

Powerful PHP integrated development environment

Dreamweaver CS6

Visual web development tools

SublimeText3 Mac version

God-level code editing software (SublimeText3)

Hot Topics

1664

1664

14

14

1422

1422

52

52

1317

1317

25

25

1268

1268

29

29

1242

1242

24

24

Getting Started With Meta Llama 3.2 - Analytics Vidhya

Apr 11, 2025 pm 12:04 PM

Getting Started With Meta Llama 3.2 - Analytics Vidhya

Apr 11, 2025 pm 12:04 PM

Meta's Llama 3.2: A Leap Forward in Multimodal and Mobile AI Meta recently unveiled Llama 3.2, a significant advancement in AI featuring powerful vision capabilities and lightweight text models optimized for mobile devices. Building on the success o

10 Generative AI Coding Extensions in VS Code You Must Explore

Apr 13, 2025 am 01:14 AM

10 Generative AI Coding Extensions in VS Code You Must Explore

Apr 13, 2025 am 01:14 AM

Hey there, Coding ninja! What coding-related tasks do you have planned for the day? Before you dive further into this blog, I want you to think about all your coding-related woes—better list those down. Done? – Let’

AV Bytes: Meta's Llama 3.2, Google's Gemini 1.5, and More

Apr 11, 2025 pm 12:01 PM

AV Bytes: Meta's Llama 3.2, Google's Gemini 1.5, and More

Apr 11, 2025 pm 12:01 PM

This week's AI landscape: A whirlwind of advancements, ethical considerations, and regulatory debates. Major players like OpenAI, Google, Meta, and Microsoft have unleashed a torrent of updates, from groundbreaking new models to crucial shifts in le

Selling AI Strategy To Employees: Shopify CEO's Manifesto

Apr 10, 2025 am 11:19 AM

Selling AI Strategy To Employees: Shopify CEO's Manifesto

Apr 10, 2025 am 11:19 AM

Shopify CEO Tobi Lütke's recent memo boldly declares AI proficiency a fundamental expectation for every employee, marking a significant cultural shift within the company. This isn't a fleeting trend; it's a new operational paradigm integrated into p

GPT-4o vs OpenAI o1: Is the New OpenAI Model Worth the Hype?

Apr 13, 2025 am 10:18 AM

GPT-4o vs OpenAI o1: Is the New OpenAI Model Worth the Hype?

Apr 13, 2025 am 10:18 AM

Introduction OpenAI has released its new model based on the much-anticipated “strawberry” architecture. This innovative model, known as o1, enhances reasoning capabilities, allowing it to think through problems mor

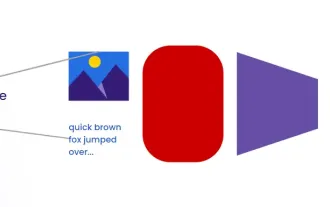

A Comprehensive Guide to Vision Language Models (VLMs)

Apr 12, 2025 am 11:58 AM

A Comprehensive Guide to Vision Language Models (VLMs)

Apr 12, 2025 am 11:58 AM

Introduction Imagine walking through an art gallery, surrounded by vivid paintings and sculptures. Now, what if you could ask each piece a question and get a meaningful answer? You might ask, “What story are you telling?

3 Methods to Run Llama 3.2 - Analytics Vidhya

Apr 11, 2025 am 11:56 AM

3 Methods to Run Llama 3.2 - Analytics Vidhya

Apr 11, 2025 am 11:56 AM

Meta's Llama 3.2: A Multimodal AI Powerhouse Meta's latest multimodal model, Llama 3.2, represents a significant advancement in AI, boasting enhanced language comprehension, improved accuracy, and superior text generation capabilities. Its ability t

Newest Annual Compilation Of The Best Prompt Engineering Techniques

Apr 10, 2025 am 11:22 AM

Newest Annual Compilation Of The Best Prompt Engineering Techniques

Apr 10, 2025 am 11:22 AM

For those of you who might be new to my column, I broadly explore the latest advances in AI across the board, including topics such as embodied AI, AI reasoning, high-tech breakthroughs in AI, prompt engineering, training of AI, fielding of AI, AI re