Reference News Network reported on October 31 According to the "Nihon Keizai Shimbun" report on October 30, Astellas Pharmaceutical Company used a dual-arm robot to achieve iPS cell (induced pluripotent stem cell) culture Automation of jobs. The company has applied to regulatory authorities to use robots to manufacture pharmaceutical products, with the goal of providing drugs for clinical trials by 2026. If manual work is completed by mechanical equipment to reduce the incidence of errors, the success rate of iPS cell culture will increase by more than 60% compared with today. Once commercialized, it will help iPS cells to be used in a wider range of fields.

The robot "Maholo" used by Astellas was developed by the Robotic Biology Institute (RBI), an emerging company founded by the Institute of Advanced Industrial Technology and a subsidiary of Yaskawa Electric.

I saw Maholo moving his arms smoothly, using a pipette to inject solution and move the cell culture plate. It is said that this two-arm robot can reproduce human movements in a smaller space than a one-arm robot.

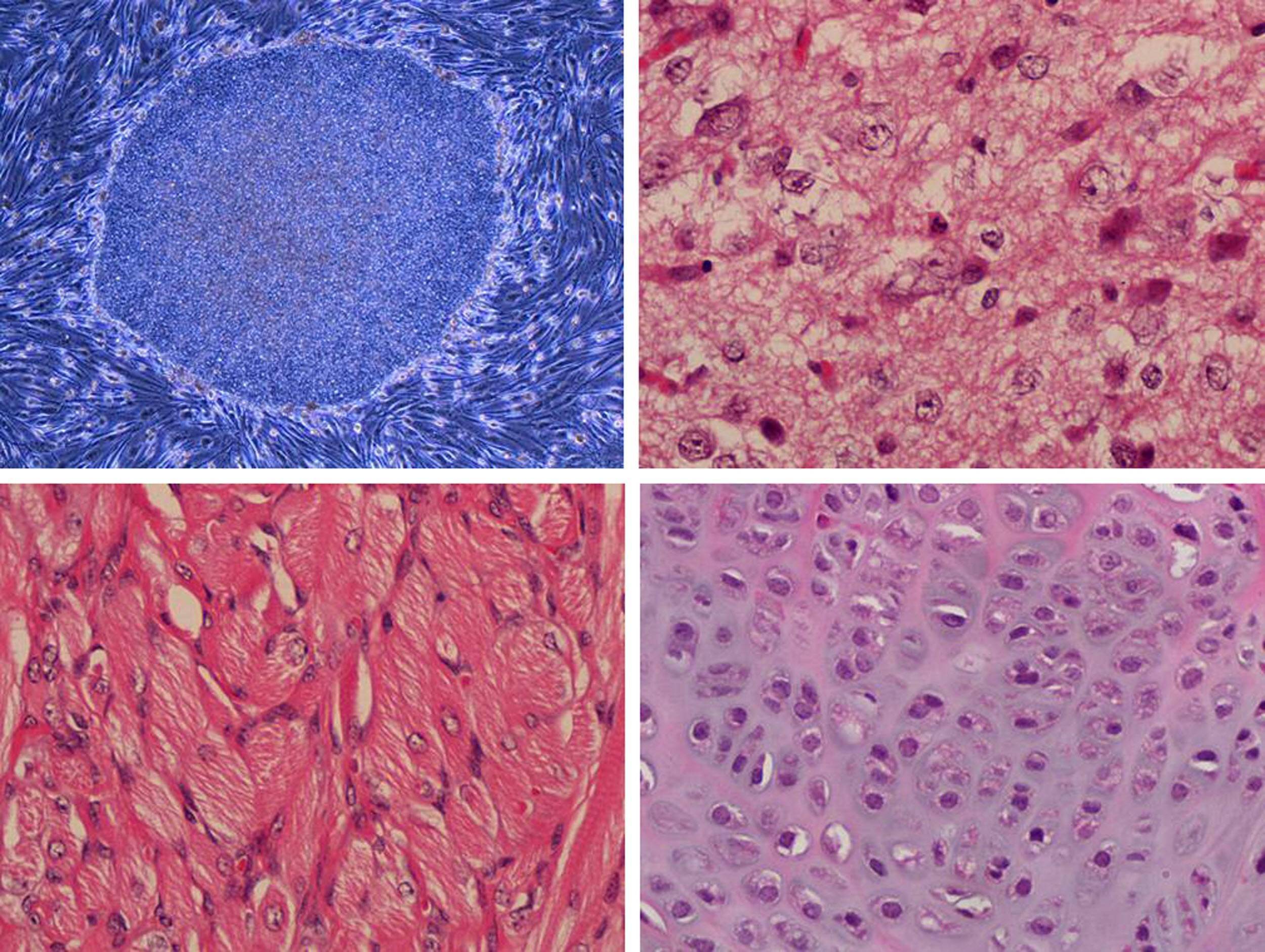

After culture and proliferation, iPS cells need to differentiate into nerve cells and blood cells according to different therapeutic purposes. This kind of work is inseparable from the skilled hands of researchers, but there are also mistakes in operation. Due to subtle differences in conditions such as temperature, there is a risk that differentiation may not match the intended use.

Even with extremely slight movements like shaking hands, Maholo can maintain a certain angle and speed to operate the tool correctly, thereby greatly improving the success rate of cell culture.

If we use a robot that can operate 24 hours a day, 365 days a year, we can repeatedly conduct high-precision experiments and compare more laboratory culture conditions. Coupled with the cooperation with artificial intelligence, it is possible to complete experiments that are hundreds or even a thousand times larger than previous experiments in the same time period.

Once you start cell culture, you must create a suitable environment to promote metabolism. Sometimes you need to work continuously for weeks or even months, and you cannot rest on Saturdays and Sundays. However, with the introduction of robots, researchers can monitor remotely, thus reducing the need for commuting.

Astellas began to introduce robots to develop new drugs using iPS cells as early as 2017. In 2023, the company will begin to verify the feasibility of robots participating in manufacturing drugs. Hideto Yamaguchi, director of the company's API Research Institute, said: "The research and development cycle can be shortened by several months, and the product can be launched earlier."

Cellular medicine is one of the key development areas of Astellas. In addition to conducting cell drug therapy trials for age-related macular degeneration, which is common in the elderly, it is also promoting related research in autoimmune diseases.

Cell drugs made by robots still need to be approved by regulatory authorities before they can go into clinical practice. According to an Astellas insider: "Cell differentiation is usually a manual operation, and there are few examples of robotic automation."

To this end, the company will negotiate with the U.S. Food and Drug Administration and the Japan Pharmaceuticals and Medical Devices Agency, and plans to supply new drugs manufactured by Maholo for clinical trials around 2026.

Other pharmaceutical giants are also stepping up their efforts to introduce robots. In October, Chugai Pharmaceutical started a demonstration experiment using robots at its research facility in Yokohama City. Through cooperation with Omron, we strive to realize the automation of cell culture and other aspects. The robot will automatically patrol the research room and carry experimental reagents to microscopes, centrifuges, refrigerators and other equipment.

The movement of cell culture plates has been experimentally undertaken by robots. Previously, Chugai Pharmaceutical introduced a system to automate the process of copying genes, and by working at night, it shortened the production time of antibody genes from five days in the past to three days.

It is said that drug research and development usually takes more than ten years, and the success rate is only one in 30,000. Deloitte Consulting is familiar with the application of digital technology in drug research and development sites. Its executive director Negishi Shoichi said: "The use of robots and artificial intelligence will improve the level and efficiency of drug research and development. If manpower can be saved, it is expected to increase cooperation among researchers to realize technology The possibility of innovation.”

The above is the detailed content of Success rate of robot cultivating iPS cells greatly increased. For more information, please follow other related articles on the PHP Chinese website!

direct3d function is not available

direct3d function is not available

My computer can't open it by double-clicking it.

My computer can't open it by double-clicking it.

Introduction to software development tools

Introduction to software development tools

Usage of Type keyword in Go

Usage of Type keyword in Go

Introduction to the main work content of the backend

Introduction to the main work content of the backend

Tutorial on buying and selling Bitcoin on Huobi.com

Tutorial on buying and selling Bitcoin on Huobi.com

How to use countif function

How to use countif function

What currency is PROM?

What currency is PROM?