Technology peripherals

Technology peripherals

AI

AI

A survey shows that about 24% of manufacturing companies in the United States are still in the AI exploration stage.

A survey shows that about 24% of manufacturing companies in the United States are still in the AI exploration stage.

A survey shows that about 24% of manufacturing companies in the United States are still in the AI exploration stage.

When thinking about the potential of AI systems to transform manufacturing, Ritu Jyoti, global AI research director at market intelligence firm IDC, mentioned windmill manufacturers.

Before using artificial intelligence, she said, if the company wanted to improve the windmill, the company would analyze the data by observing a working windmill prototype, a process that would take weeks. Now with artificial intelligence, manufacturers can use digital twins (digital models of windmills) to significantly shorten this process, and use machine learning and artificial intelligence to create and simulate improvements.

Jyoti said: “Sometimes it’s not even possible for manufacturers to do all the measuring work because many jobs are physically challenging for humans, so they use drones and artificial intelligence technology to do it, This is a win for digital.” The manufacturer now considers this technology of artificial intelligence and machine learning to be crucial. "Because if they don't do that, they can't keep up with the changes in the market," she said.

(Source: see watermark)

(Source: see watermark)

Disruptions to manufacturing and supply chains have prompted businesses to engage in digital transformation as they seek ways to stay competitive. For manufacturers, technological disruption, including artificial intelligence, offers opportunities to make manufacturing more efficient, safer and more sustainable.

Companies can use AI to streamline processes and reduce downtime, adopt robots that increase safety and speed, allow AI to quickly detect anomalies using computer vision technology, and develop AI systems to process large amounts of data to identify patterns and predictions client needs.

Pierre Goutorbe, director of AI solutions for energy and manufacturing at Dataiku, said: “In manufacturing, when business people are able to work with data experts, they can use data and AI to gain valuable insights. That's when we see the maximum benefit when we take the information and ultimately take action to improve our processes." He also said: "The more employees are familiar with AI and using it in their daily lives, the more we will see its benefits."

Amid supply chain disruptions and worker shortages, manufacturing has been innovating to stay ahead of the global market.

However, a June 2023 study by Dataiku and Databricks found that manufacturing lags behind other industries in AI applications, with about a quarter (24%) of companies still exploring AI applications or experimental stage, while only about one-fifth (19%) of companies in all other industries are still in their infancy.

The above is the detailed content of A survey shows that about 24% of manufacturing companies in the United States are still in the AI exploration stage.. For more information, please follow other related articles on the PHP Chinese website!

Hot AI Tools

Undresser.AI Undress

AI-powered app for creating realistic nude photos

AI Clothes Remover

Online AI tool for removing clothes from photos.

Undress AI Tool

Undress images for free

Clothoff.io

AI clothes remover

AI Hentai Generator

Generate AI Hentai for free.

Hot Article

Hot Tools

Notepad++7.3.1

Easy-to-use and free code editor

SublimeText3 Chinese version

Chinese version, very easy to use

Zend Studio 13.0.1

Powerful PHP integrated development environment

Dreamweaver CS6

Visual web development tools

SublimeText3 Mac version

God-level code editing software (SublimeText3)

Hot Topics

1359

1359

52

52

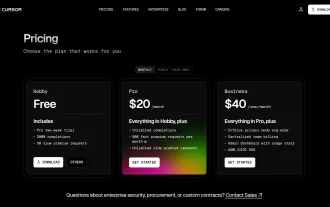

I Tried Vibe Coding with Cursor AI and It's Amazing!

Mar 20, 2025 pm 03:34 PM

I Tried Vibe Coding with Cursor AI and It's Amazing!

Mar 20, 2025 pm 03:34 PM

Vibe coding is reshaping the world of software development by letting us create applications using natural language instead of endless lines of code. Inspired by visionaries like Andrej Karpathy, this innovative approach lets dev

How to Use DALL-E 3: Tips, Examples, and Features

Mar 09, 2025 pm 01:00 PM

How to Use DALL-E 3: Tips, Examples, and Features

Mar 09, 2025 pm 01:00 PM

DALL-E 3: A Generative AI Image Creation Tool Generative AI is revolutionizing content creation, and DALL-E 3, OpenAI's latest image generation model, is at the forefront. Released in October 2023, it builds upon its predecessors, DALL-E and DALL-E 2

Top 5 GenAI Launches of February 2025: GPT-4.5, Grok-3 & More!

Mar 22, 2025 am 10:58 AM

Top 5 GenAI Launches of February 2025: GPT-4.5, Grok-3 & More!

Mar 22, 2025 am 10:58 AM

February 2025 has been yet another game-changing month for generative AI, bringing us some of the most anticipated model upgrades and groundbreaking new features. From xAI’s Grok 3 and Anthropic’s Claude 3.7 Sonnet, to OpenAI’s G

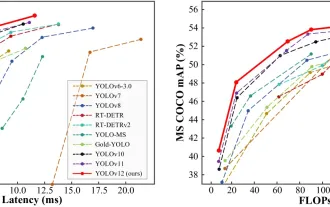

How to Use YOLO v12 for Object Detection?

Mar 22, 2025 am 11:07 AM

How to Use YOLO v12 for Object Detection?

Mar 22, 2025 am 11:07 AM

YOLO (You Only Look Once) has been a leading real-time object detection framework, with each iteration improving upon the previous versions. The latest version YOLO v12 introduces advancements that significantly enhance accuracy

Sora vs Veo 2: Which One Creates More Realistic Videos?

Mar 10, 2025 pm 12:22 PM

Sora vs Veo 2: Which One Creates More Realistic Videos?

Mar 10, 2025 pm 12:22 PM

Google's Veo 2 and OpenAI's Sora: Which AI video generator reigns supreme? Both platforms generate impressive AI videos, but their strengths lie in different areas. This comparison, using various prompts, reveals which tool best suits your needs. T

Google's GenCast: Weather Forecasting With GenCast Mini Demo

Mar 16, 2025 pm 01:46 PM

Google's GenCast: Weather Forecasting With GenCast Mini Demo

Mar 16, 2025 pm 01:46 PM

Google DeepMind's GenCast: A Revolutionary AI for Weather Forecasting Weather forecasting has undergone a dramatic transformation, moving from rudimentary observations to sophisticated AI-powered predictions. Google DeepMind's GenCast, a groundbreak

Which AI is better than ChatGPT?

Mar 18, 2025 pm 06:05 PM

Which AI is better than ChatGPT?

Mar 18, 2025 pm 06:05 PM

The article discusses AI models surpassing ChatGPT, like LaMDA, LLaMA, and Grok, highlighting their advantages in accuracy, understanding, and industry impact.(159 characters)

Is ChatGPT 4 O available?

Mar 28, 2025 pm 05:29 PM

Is ChatGPT 4 O available?

Mar 28, 2025 pm 05:29 PM

ChatGPT 4 is currently available and widely used, demonstrating significant improvements in understanding context and generating coherent responses compared to its predecessors like ChatGPT 3.5. Future developments may include more personalized interactions and real-time data processing capabilities, further enhancing its potential for various applications.