After the LiveDrive direct-drive motor was officially unveiled at the Hannover Industrial Fair in 2016, many experts predicted that this new structure would have great potential in the future. At that time, some scholars pointed out that the unique design of this combination of copper coils and magnets has greater torque than the non-traditional gear coupling structure, but is quieter and more precise. Just like new energy engines for cars, it will bring a A change in transmission method.

In recent years, domestic home robot companies have achieved great results in the global market. In the face of more fierce competition, direct drive motors have quickly become the focus of companies seeking breakthrough changes in products from a relatively unpopular field. Especially for mid-to-high-end home robots, In order to create more distinctive new selling points, meet consumers' picky and diverse product needs, and pursue more stable and reliable ultimate performance, we must pass increasingly stringent national testing standards , direct drive motors are undoubtedly the best choice.

▍A new choice for home robots

For industries such as robots, the emergence of direct drive motors does mean the advancement of transmission device technology. This final product is a revolutionary change based on innovation in materials science and has made great progress in many aspects

In principle, direct drive motors directly transmit power from the motor to the moving parts of the robot. Compared with gear transmission actuators that inevitably have mechanical delays, eliminates the need for complex reducer redundancy in the middle. Mechanism, not only has relatively richer and more accurate safety functions, but also can be completely silent. It also has obvious advantages in maintainability and scalability, and its service life and battery life have been greatly improved. It can be said that the direct-drive precision power solution truly brings more possibilities to robot innovation.

Currently, driven by market demand, domestic direct-drive motor manufacturers represented by Benmo Technology are taking advantage of the situation to rise rapidly. It is reported that the leading company "Benmo Technology" has the full-stack capability of "self-research, self-production, and self-sales". Its factory has currently completed the construction of 5 self-built production lines, and its annual production capacity can reach one million levels. . Not long ago, Benmo Technology released the new M0603A motor. This product already has the characteristics of more obvious silence, compact structure, easy installation, stable operation, small size, highly integrated control, unique driver control algorithm and high precision. The sensor has helped customers achieve a disruptive improvement in the intelligent power experience of the product. It has been successfully used in the latest smart floor scrubber product H30 of Chuimi. Its "new experience" of intelligent control through dual driving wheels has made Chuimi Mi products have become another benchmark in the household product market and have received unanimous praise from consumers. At present, the M0603A motor has become the first choice for "power actuator" in products such as household robots, small AGV drive wheels, toy drive wheels, and educational development vehicle platforms.

(M0603A picture)

In addition, while pursuing high performance and the ultimate experience, Benmo Technology has also achieved the ultimate cost-effectiveness. The price of a single M0603A motor is only equivalent to the price of a bunch of grapes, and it is currently providing power solutions for more and more household robots. It is foreseeable that driven by the huge global market, Benmo Technology, a pioneer in the continuous research and development of a new driving structure, will have more sales in the future.

▍Another masterpiece in the industry

The reason is that for home robot companies, the core of the market has always been to improve consumer experience and purchase desire, and accelerate entry into various application scenarios. Therefore, battery life, protection level, noise, demand scalability, safety and other aspects are core influencing factors and are also important evaluation basis for evaluation agencies and consumers.

There is no doubt that the M0603A motor, a groundbreaking upgrade product, has significant advantages in these aspects. It has high efficiency, high precision, high speed, stability, low maintenance cost and strong adaptability, making the new design of home robots possible.

For example, operating efficiency and durability are the focus of consumers, which means that home robots need to be able to run for a long time on a single charge and have a long service life. The successful application of M0603A motor makes home robots more practical and cost-effective. In terms of product structure design, the M0603A motor adopts a professional magnetic circuit design, which optimizes the magnetic field distribution of the motor, increases the torque density and power density of the motor, reduces the energy consumption of the motor, and improves the operating efficiency and performance of the motor. In addition, the motor can also reduce temperature rise and noise, reduce the motor failure rate and the number of repairs, thereby extending the service life of the motor

Of course, another effect brought by the minimalist and compact design is the improvement of the protection level. The protection level of M0603A reaches IP64, providing large integrated redundancy in basic performance indicators, helping home robots enter more scenarios.

(M0603A waterproof test chart)

It is foreseeable that since direct drive motors have fewer parts that are prone to wear or damage, the maintenance frequency of home robots equipped with direct drive motors will be greatly reduced as time goes by, thereby further extending the service life And it reduces the comprehensive utilization cost, which is crucial for the long-lasting and reliable performance of the product, and helps to enhance the corporate brand and product reputation.

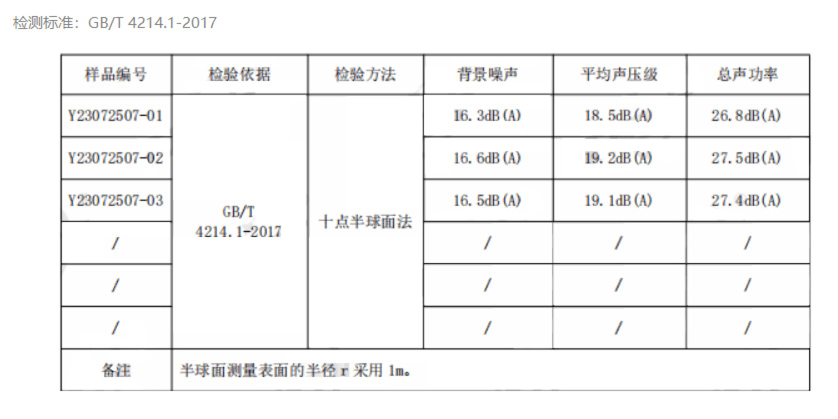

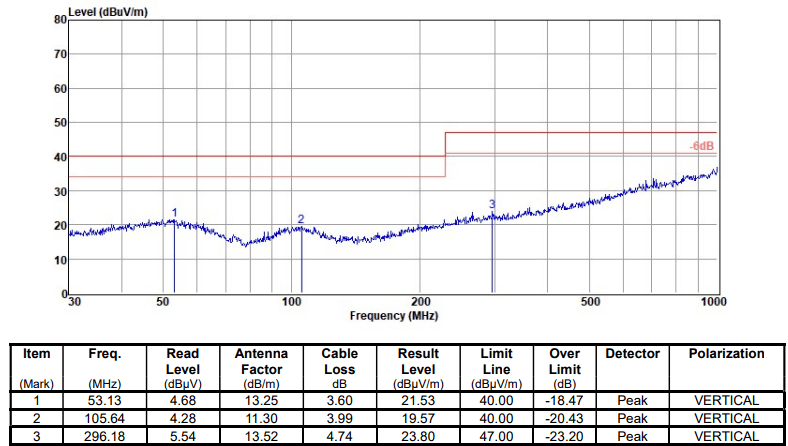

In addition, noise issues have also been a focus of concern for consumers. Market results have proven that the quiet operating experience of home robots is less disruptive to home residents and is more likely to be favored by consumers. Compared with the traditional "brush motor + reducer" or "brushless motor + reducer" transmission solution, the direct drive motor is quieter, and its silent effect far exceeds industry testing standards.

(M0603A motor silence test data)

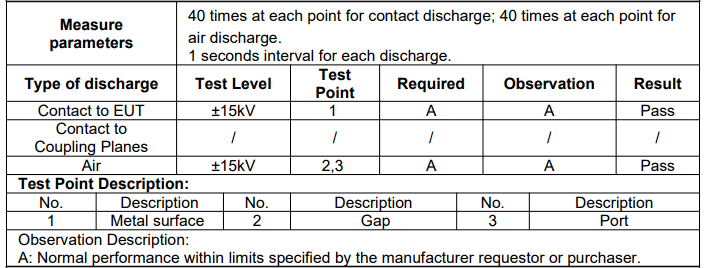

Static electricity and product reliability are increasingly stringent testing requirements, another issue that home robots need to pay attention to. M0603A reaches the standard of plus or minus 15KV in ESD index, which far exceeds the plus or minus 8KV standard of the household industry national standard. In terms of EMC indicators, M0603A also performs stably, which means it has excellent anti-electromagnetic interference capabilities

The content that needs to be rewritten is: (ESD and EMC data of M0603A motor)

How to bring consumers a deeper experience? That will inevitably require products that can serve the broader functional needs of robots. From the perspective of motor control, M0603A is highly integrated with drive and control. It has built-in torque loop and speed loop, which will provide robot companies with a more precise control and feedback mechanism to help robots achieve rapid acceleration and deceleration. Achieve precise motion control and help robot companies make upper-level control of the entire machine simpler.

On the one hand, this kind of precision is crucial for the future product expansion of the home. For example, M0603A can help home robots handle delicate objects or perform tasks that require precise positioning more easily, achieve route navigation, object manipulation or angle fine-tuning, reduce repetitive motion trajectories, and become smarter and smarter.

On the other hand, the M0603A direct drive motor is more compact than the gear motor, so it can achieve a smaller and more streamlined robot design to meet more functional development needs. In addition, by integrating single bus control, communication is simpler and more convenient, and the cost is lower, which can better assist the functional linkage of the entire machine and create more application scenarios

It is worth mentioning that in order to adapt to products with wheeled applications such as handheld smart floor washers and sweeping robots, M0603A has an anti-winding structure design at the connection end. This design can prevent hair from entering and getting entangled during work, effectively protecting the internal structure, reducing the failure rate, and improving the durability of the product

▍"Behind the price of a bunch of grapes"

The M0603A direct drive motor not only achieves ultimate performance, but also stands out as the king of cost performance. Compared with direct drive motors of the same type, it achieves high-end performance at a lower cost

How does Benmo Technology achieve this? According to the understanding of the Robot Lecture Hall, Benmo Technology is customer-centered, and the optimization of the entire process from customer needs and market research to solution design, test verification, batch delivery and quality control management is an important reason for its success

In the stages of customer needs, market research and solutions, Benmo Technology’s core parts department has a R&D and technical team of dozens of people. It responds quickly and quickly according to customer projects and sets up a special project team to go deep into customer scenarios. , conduct a comprehensive analysis of customer needs in terms of market, product definition, technology, etc., and combine Benmo Technology’s years of accumulation in core direct drive technology and experience in robot power design to provide scientific and rational solutions.

In the actual testing and verification phase of the product, Benmo Technology has improved the development and testing equipment, and has all-round product testing design solutions and testing verification capabilities, including 9 motor performance with different ranges The test system provides measurement functions for motor voltage, current, power, torque, speed, and efficiency. It is also equipped with advanced oscilloscopes, electronic loads, high-voltage differential probes and other equipment for hardware board-level power supply and signal integrity testing. Not only that, Benmo has also established a professional testing and verification center and recruited an experienced team to help customers truly achieve product testing through environmental reliability, electromagnetic compatibility, safety and safety regulations, hardware white box, software functions, hardware functions, Covers all aspects of testing including scenarios to meet more customers’ customized development needs for product models.

In the product batch delivery stage, Scaling is the basis for stabilizing product yield and reducing unit shared costs. Benmo Technology not only has a streamlined and complete process flow, but also has a high degree of semi-automation in the production line, and the production line can realize rapid switching and duplication, which provides guarantee for its batch delivery. It is understood that the current production capacity of each semi-automated line of Benmo Technology reaches 50,000-100,000 units/month, which can fully meet the batch and emergency delivery requirements of customer orders.

In order to further reduce costs and improve efficiency, we have introduced many digital components into our production system to improve the efficiency of production line replacement and maintenance. For example, through the use of ERP systems and MES systems, we have realized the digitization and visualization of production management. We can query information such as order plans, production status, FPY status, and production abnormality analysis reports anytime and anywhere, thus greatly reducing maintenance shutdowns and other issues. occur

After continuously optimizing each production unit, this huge production system not only realizes the latest production technology and test reliability and traceability such as digitization, foolproofing and one-click operation of production equipment and testing instruments, but also A complete engineering and technical team has been deployed to ensure that various emergencies and difficult problems on the production line can be solved at any time

As more and more household robots are recognized in the market, In the early product design stage, in order to develop direct-drive motors that are more suitable for various types of products, Benmo Technology often First, cooperate with customers to carry out all-round product inspection design and test verification, make various inspection operation guidance documents detailed and pictorial, various quality control record forms detailed and specialized, and continue regular spot inspections and first inspections , and work with customers to achieve the full product design and finalization process.

The reason why Benmo Technology can more easily complete comprehensive monitoring and strict control from materials, manufacturing to finished products, as well as continuously improve products, meet customer requirements, and ensure that product yields exceed the level of the motor industry is mainly due to It has the ability to customize development and design finalization with customers on the production side. This ability is based on a complete quality management system and relies on the driving force of a quality management team with many years of experience in the motor industry to solve various quality problems quickly, accurately and in a closed loop to help users continuously improve their products.

In this article, we discuss some important issues and propose some solutions. By analyzing the current situation, we recognize the current challenges and discuss future development directions. However, we must remember that this is just the beginning. We need to keep working hard and exploring to achieve the future we envision. First, we need to strengthen the education system and cultivate more innovative and practical talents. Education is the key to social progress, and we must be committed to improving the quality of education and encouraging students to develop all-round abilities. Secondly, we need to increase scientific and technological innovation. The development of science and technology is crucial to economic growth and social progress. We should strengthen scientific research and provide more support and resources to promote the development of scientific and technological innovation. In addition, we also need to strengthen our awareness of environmental protection. Environmental issues have become the focus of global attention. We must take action to reduce pollution and protect the ecological environment. Everyone should be aware of their responsibilities and actively participate in environmental protection. Finally, we should strengthen international cooperation and jointly respond to global challenges. Many global problems can only be solved through cooperation. We should strengthen communication and cooperation with other countries to jointly promote the development of the world. All in all, we face many challenges, but also many opportunities. Only through hard work and cooperation can we achieve the future we desire. Let us work together to contribute to our country and society

Driven by technological progress and changes in consumer demand, Household robots represented by sweeping robots, smart floor washers, air purifiers, etc. have seen a very significant trend and speed of product innovation in recent years . In order to meet environmental protection and energy-saving requirements, improve product cleaning performance, improve navigation autonomy and efficiency, and increase the multi-layer and multi-region operation capabilities of robots, home robot manufacturers have begun to choose and continuously optimize the components and combinations of home robots.

Direct-drive motors not only have higher energy efficiency and almost no noise, but also have a long service life and can reduce the failure rate. It also provides more space for the design and aesthetics of home robots with the advantages of smaller size and high integration, which will help add more fashionable and technological elements to perfectly integrate with modern homes.

Of course, before this, although direct drive motors had many advantages, they also had limitations such as increased costs and complexity of design and control systems. However, Benmo Technology has made breakthroughs in key core technologies in hardware. Continuously optimize algorithms in software, build a fully independent research and development system in research and development, actively build a research and development team in product performance, materials, processes, structures, algorithms, etc., and improve lean manufacturing capabilities, delivery capabilities and quality control in production inspection, achieving stronger solution output at the product and design levels.

It can be foreseen that as people’s specific requirements and expected tasks for home robots continue to increase, home robot manufacturers will inevitably continue to evolve their products according to different applications, and direct-drive motors are undoubtedly the best way to improve the overall performance and functions of robots. best choice.

The above is the detailed content of Direct-drive motors empower home robots, and Benmo Technology creates a new intelligent power experience. For more information, please follow other related articles on the PHP Chinese website!