News from this site on November 24, according to official news from FAW Hongqi, the Chassis Development Department of the New Energy Development Institute of Hongqi R&D Institute ushered in new results. developed the first domestic suspension K&C fully automated simulation tool - " K&C Auto” claims to increase simulation and development efficiency by 500%.

Notes from this site: Suspension K&C characteristics refer to suspension kinematic characteristics (Kinematic) and elastic kinematic characteristics (Compliance) , affected by the characteristics of suspension hard points and elastic parts, plays a decisive role in the vehicle's handling, stability and ride comfort. In the development process of dynamic performance, the design and optimization of suspension K&C characteristics are crucial, involving hundreds or even thousands of rounds of K&C characteristics simulation calculations.

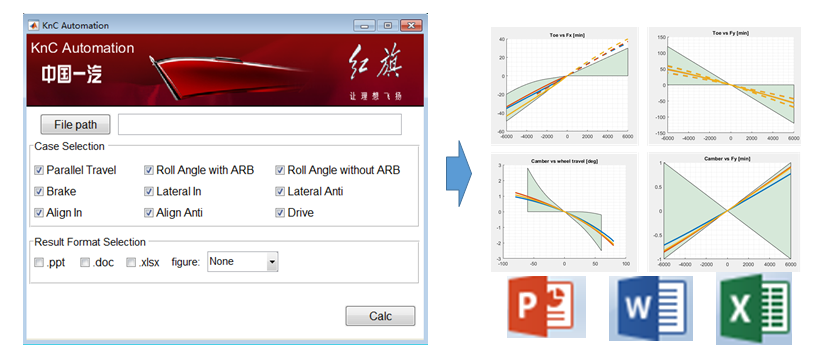

According to reports, in order to solve the pain points of long-term and error-prone K&C manual simulation calculations, the dynamics development team independently developed the K&C Auto automated simulation tool, realizing K&C characteristic simulation and processing with one click, fundamentally solve the pain points of K&C performance development.

The K&C Auto tool includes three functional modules: K&C simulation, result processing and report output, which can support the entire K&C performance development process:

Simplify operations and improve efficiency

In the automatic simulation module, we can realize the simulation of more than 10 typical K&C working conditions. By using load condition simulation setup program mapping technology, we are able to ensure standardization of K&C characteristic simulations. At the same time, we also combined the developed Matlab and ADAMS tool chains and used batch processing technology to achieve one-click simulation of K&C characteristics in all working conditions

Fast analysis and efficient processing

By optimizing the program architecture and algorithm, the data parsing path is improved in the automatic post-processing module, which solves the problem of slow parsing speed of res simulation result files and increases the parsing speed of res files by 80%. At the same time, combined with the development of methods and programs for processing more than 70 K&C key performance indicators, the simulation post-processing time has been shortened from 4 hours to 1 minute, greatly improving the efficiency of data processing

Intelligent analysis, Ready-to-use

In the K&C Auto report automatic output module, based on the K&C benchmarking database and combined with big data analysis, the K&C target automatic setting function is developed, which can automatically position based on vehicle basic information and performance By setting K&C goals and combining with the automatic report output function, K&C simulation report files in multiple formats can be generated, enabling ready-to-use imitation and real-time output of reports, further reducing performance development workload and improving development efficiency.

Advertising Statement: This article contains external jump links (including but not limited to hyperlinks, QR codes, passwords, etc.), which are designed to provide more information and save screening time. The results are only refer to. Please note that all articles on this site contain this statement

The above is the detailed content of Hongqi Motors develops China's first fully automated suspension K&C simulation tool, achieving efficiency improvement of 500%. For more information, please follow other related articles on the PHP Chinese website!