Technology peripherals

Technology peripherals

It Industry

It Industry

The power semiconductor market is slowing down, and reports show that Chinese companies are turning to 12-inch wafers and IGBT transistors

The power semiconductor market is slowing down, and reports show that Chinese companies are turning to 12-inch wafers and IGBT transistors

The power semiconductor market is slowing down, and reports show that Chinese companies are turning to 12-inch wafers and IGBT transistors

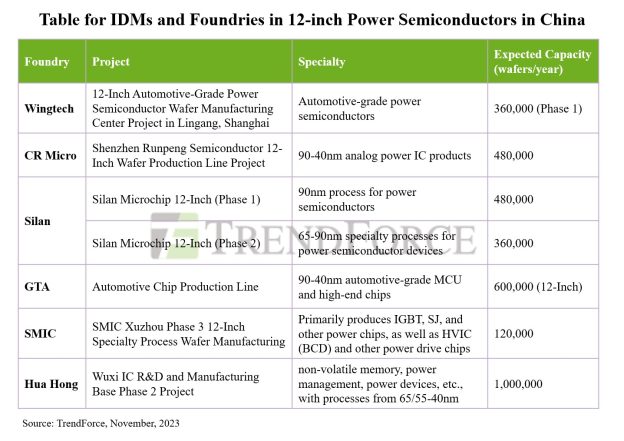

News from this site on November 28, according to the latest report released by TrendForce, against the background of the slowdown in the power semiconductor market, Mainland Chinese companies have sought breakthroughs in the fields of 12-inch wafers and IGBTs, and have achieved Brilliant results.

In the first half of 2023, the revenue growth rate of well-known Chinese wafer foundries such as SMIC, Hua Hong Semiconductor, Hefei Jinghe Integrated Circuit (Nexchip) and Shaoxing Semiconductor Manufacturing Co., Ltd. (SMEC) Slow down

Among them, only Huahong’s revenue increased slightly, while SMIC, Jinghe Integrated and SMIC Integrated’s revenue fell by 19.29% year-on-year respectively. , 50.43%, 24.08%. Due to the downturn in the consumer electronics, personal computer and communications markets, the overall performance of China's wafer fabs is entering a downward cycle.

In the first half of 2023, Huahong’s discrete device revenue The year-on-year growth was 33.04%, but the growth rate was lower than the same period in 2022.

The number of listed power semiconductor companies in the top ten with negative revenue growth increased from 1 to 4 in 2022, and the number of companies with negative net profit growth increased from 1 to 8.

Although overall growth has slowed, IGBT has become an important driving force for power semiconductors.

Companies such as Silan Micro and China Resources Micro have begun mass production of IGBTs, and their IGBT business is growing rapidly. In addition, Wingtech Technology is also entering the IGBT field. It is worth noting that as of January to July 2023, 17 IGBT projects have been launched or signed, with a cumulative investment of more than 15 billion yuan, showing the rapid expansion of Chinese companies in the IGBT field

China's major Power semiconductor manufacturers are transitioning from 8-inch wafers to 12-inch wafers. Huahong has implemented 12-inch production capacity, and the expansion of the Wuxi Phase II project is in progress. In June 2023, SMIC’s Phase III 12-inch special process silicon wafer production line will produce the first batch of 10,000 wafers. In the field of IDM, Wingtech Technology, Silan, China Resources Micro and other companies are actively building 12-inch wafer fabs, and part of the production capacity has been put into operation. Discrete devices generally refer to all basic circuit components with a single function, such as transistors. , diodes, resistors, capacitors, inductors, etc. Discrete devices in the narrow sense specifically refer to basic components of single-function circuits made of semiconductor materials that cannot be integrated into integrated circuits due to functional, volume, and technical constraints.

The insulated gate bipolar transistor (IGBT) is an ideal transistor for high voltage and high current applications. IGBTs have a rated voltage range of 400V to 2000V and a rated current range of 5A to 1000A. IGBTs are widely used in industrial applications (such as inverter systems and uninterruptible power supplies (UPS)), consumer applications (such as air conditioners and induction cookers), and automotive applications (such as electric vehicle (EV) motor controllers)

This site attaches the original address of the report, and interested users can read it in depth.

Advertising Statement: This article contains external jump links (including but not limited to hyperlinks, QR codes, passwords, etc.), which are intended to provide more information and save screening time. The results are for reference only. Please note that all articles on this site contain this statement

The above is the detailed content of The power semiconductor market is slowing down, and reports show that Chinese companies are turning to 12-inch wafers and IGBT transistors. For more information, please follow other related articles on the PHP Chinese website!

Hot AI Tools

Undresser.AI Undress

AI-powered app for creating realistic nude photos

AI Clothes Remover

Online AI tool for removing clothes from photos.

Undress AI Tool

Undress images for free

Clothoff.io

AI clothes remover

Video Face Swap

Swap faces in any video effortlessly with our completely free AI face swap tool!

Hot Article

Hot Tools

Notepad++7.3.1

Easy-to-use and free code editor

SublimeText3 Chinese version

Chinese version, very easy to use

Zend Studio 13.0.1

Powerful PHP integrated development environment

Dreamweaver CS6

Visual web development tools

SublimeText3 Mac version

God-level code editing software (SublimeText3)

Hot Topics

1387

1387

52

52

Innolux plans to mass-produce fan-out panel-level semiconductor packaging technology by the end of the year

Aug 07, 2024 pm 06:18 PM

Innolux plans to mass-produce fan-out panel-level semiconductor packaging technology by the end of the year

Aug 07, 2024 pm 06:18 PM

According to news from this site on August 6, Yang Zhuxiang, general manager of Innolux Corporation, said yesterday (August 5) that the company is actively deploying and promoting semiconductor fan-out panel-level packaging (FOPLP) and is expected to mass-produce ChipFirst before the end of this year. The contribution of process technology to revenue will be apparent in the first quarter of next year. Fenye Innolux stated that it is expected to mass-produce the redistribution layer (RDLFirst) process technology for mid-to-high-end products in the next 1-2 years, and will work with partners to develop the most technically difficult glass drilling (TGV) process, which will take another 2-3 years. It can be put into mass production within a year. Yang Zhuxiang said that Innolux’s FOPLP technology is “ready for mass production” and will enter the market with low-end and mid-range products.

TrendForce: Nvidia's Blackwell platform products drive TSMC's CoWoS production capacity to increase by 150% this year

Apr 17, 2024 pm 08:00 PM

TrendForce: Nvidia's Blackwell platform products drive TSMC's CoWoS production capacity to increase by 150% this year

Apr 17, 2024 pm 08:00 PM

According to news from this site on April 17, TrendForce recently released a report, believing that demand for Nvidia's new Blackwell platform products is bullish, and is expected to drive TSMC's total CoWoS packaging production capacity to increase by more than 150% in 2024. NVIDIA Blackwell's new platform products include B-series GPUs and GB200 accelerator cards integrating NVIDIA's own GraceArm CPU. TrendForce confirms that the supply chain is currently very optimistic about GB200. It is estimated that shipments in 2025 are expected to exceed one million units, accounting for 40-50% of Nvidia's high-end GPUs. Nvidia plans to deliver products such as GB200 and B100 in the second half of the year, but upstream wafer packaging must further adopt more complex products.

SK hynix's innovative semiconductor CMP polishing pad technology enables sustainable use

Dec 28, 2023 pm 11:04 PM

SK hynix's innovative semiconductor CMP polishing pad technology enables sustainable use

Dec 28, 2023 pm 11:04 PM

According to news from this website on December 27, according to Korean media ETNews, SK Hynix has recently developed reusable CMP polishing pad technology, which can not only reduce costs, but also enhance ESG (environmental, social, governance) management. SK Hynix said that they will first deploy reusable CMP polishing pads in low-risk processes and gradually expand their application scope. Note: CMP technology is to make the surface of the material to be polished under the combined action of chemicals and mechanics. A process to achieve the required flatness. The chemical components in the polishing fluid react chemically with the material surface to form a softened layer that is easy to polish. The polishing pad and abrasive particles in the polishing fluid physically and mechanically polish the material surface to remove the softened layer. Source: Dinglong shares in CM

What is the main difference between semiconductor read-only memory and semiconductor random access memory?

Dec 09, 2020 am 09:57 AM

What is the main difference between semiconductor read-only memory and semiconductor random access memory?

Dec 09, 2020 am 09:57 AM

The main difference is that semiconductor read-only memory ROM can store information permanently, while semiconductor random access memory RAM will lose information when the power is turned off. The characteristic of ROM is that it can only read information but cannot write information; and the content will not be lost after power is turned off, and it will automatically restore after powering on. The characteristic of RAM is its fast reading and writing speed. Its biggest disadvantage is that the contents inside it disappear immediately after the power is turned off.

Sony Group: Its semiconductor factories concealed emissions of harmful substances

Jul 12, 2024 pm 02:09 PM

Sony Group: Its semiconductor factories concealed emissions of harmful substances

Jul 12, 2024 pm 02:09 PM

According to reports from this website on July 8, based on reports from Nikkei and Japan's "Jiji News Agency", on the 8th (today) local time, Sony Semiconductor Manufacturing Company, a semiconductor manufacturer under the Sony Group, announced that the company had discharged harmful chemicals outside the factory. , and no notification was made. The company said this was due to an input error and an imperfect confirmation system. In fiscal years 2021 and 2022, the camera image sensor factory located in Kikuyo Town, Kumamoto Prefecture, incorrectly reported its emissions of chemical substances as 0. The actual situation was that there were emissions of "waste without harmless treatment." The plant emits hydrogen fluoride, which is commonly used in semiconductor processing and cleaning. Note from this site: Hydrogen fluoride is harmful to the human body and can cause respiratory diseases and even life-threatening effects when inhaled. sony half

Samsung plans to invest 10 trillion won in semiconductor equipment and purchase ASML EUV lithography machines in large quantities

Nov 15, 2023 pm 12:33 PM

Samsung plans to invest 10 trillion won in semiconductor equipment and purchase ASML EUV lithography machines in large quantities

Nov 15, 2023 pm 12:33 PM

Samsung plans to increase the import of more ASML extreme ultraviolet (EUV) lithography equipment, according to a report from South Korea's Electronic News Today. Although the confidentiality clause in the contract did not disclose specific details, according to securities market news, this agreement will allow ASML to A total of 50 sets of equipment will be provided within five years. The unit price of each equipment is approximately 200 billion won (approximately 1.102 billion yuan), and the total value can reach 10 trillion won (approximately 55.1 billion yuan). It is currently unclear what the contract The product is an existing EUV lithography equipment or a next-generation "HighNAEUV" lithography equipment. However, the biggest problem with current EUV lithography equipment is limited output. According to officials, it is "more complex than satellite components" and can only be produced in very limited quantities each year. according to

It is reported that Pioneer International Semiconductor acquires AUO's Singapore factory to build an advanced 12-inch automotive chip wafer fab

Oct 31, 2023 pm 12:37 PM

It is reported that Pioneer International Semiconductor acquires AUO's Singapore factory to build an advanced 12-inch automotive chip wafer fab

Oct 31, 2023 pm 12:37 PM

According to news from this site on October 31, the Economic Daily learned from industry insiders that Pioneer International Semiconductor/World Advanced (VIS) is currently negotiating with AUO's Singapore factory to acquire the land and equipment held by the latter and use it to Construction of the first 12-inch wafer fab. Source: AUO’s official website Pioneer International Semiconductor plans to invest US$2 billion (approximately RMB 14.64 billion) to produce chips, mainly for the automotive field. According to reports, Pioneer International Semiconductor will hold a relevant meeting on November 7. AUO plans to hold a relevant meeting on October 31. The two companies have not yet issued official comments on the relevant rumors. Reports indicate that AUO plans to gradually withdraw its development focus in Singapore from manufacturing to establishing a regional service center. This Singapore factory was established in 201

TSMC's Kumamoto plant plans to start production in April 2024, and is expected to achieve large-scale mass production in Q4, reaching a monthly production capacity of 55,000 12-inch wafers.

Dec 18, 2023 pm 09:25 PM

TSMC's Kumamoto plant plans to start production in April 2024, and is expected to achieve large-scale mass production in Q4, reaching a monthly production capacity of 55,000 12-inch wafers.

Dec 18, 2023 pm 09:25 PM

The No. 1 factory in Kumamoto Prefecture under construction by TSMC is scheduled to hold an opening ceremony in late February next year, and is scheduled to enter the final stage of production preparations in the second quarter (April to June). According to Nikkei, TSMC’s Japanese subsidiary (JASM) President Yuichi Hota said that the construction of TSMC's factory in Kumamoto is progressing smoothly and is about to be completed. They plan to start equipment import and installation in October. It is expected that TSMC’s Kumamoto factory will be put into production in April 2024 and mass production will begin in the fourth quarter. The monthly production capacity will reach 55,000 12-inch wafers. When mentioning supply chain partners, he pointed out that in addition to TSMC’s existing suppliers , and 120 Japanese companies have joined the cooperation. Currently, Japanese companies account for approximately 25% of procurement in the supply chain.