According to news from this site on December 1, Changan Automobile said in a survey that it is developing leading solid-state batteries and will gradually start mass production and application in 2025, with a weight energy density of 350-500Wh/kg and a volume energy density of 750 -1000Wh/L, fully popularized in 2030.

In addition, Changan Automobile is developing prototype cell designs for new batteries such as lithium-sulfur batteries and metal batteries. It is expected that the energy density will exceed 1300-1500Wh/kg, and it strives to achieve on-board applications in 2035.

On the technical route, Changan Automobile focuses on breakthroughs in battery technology. Carry out technical research around liquid battery material modification and system optimization to continuously improve battery energy density. The charging rate can reach 3C for application, 5C for popularization, and 7C for pre-research. The fastest charging time is 7 minutes and a range of 400 kilometers.

We are deeply involved in the development of new electrolyte materials and key processes for semi-solid and solid-state batteries. Based on the needs of complete vehicles, we are developing leading solid-state batteries, which will be gradually mass-produced and applied from 2025, with a weight energy density of 350- 500Wh/kg, volumetric energy density 750-1000Wh/L, and will be fully popularized in 2030.

In terms of new batteries, prototype cell designs for new batteries such as lithium-sulfur batteries and metal batteries are being carried out. It is expected that the energy density will exceed 1300-1500Wh/kg, and we strive to achieve on-board applications in 2035.

In addition to structural innovation and material system innovation, the company will also carry out system integration innovation. Focusing on solving problems such as energy replenishment efficiency, intrinsic safety, full-temperature and full-scenario applications, artificial intelligence and large model applications, we continue to bring leading technical solutions.

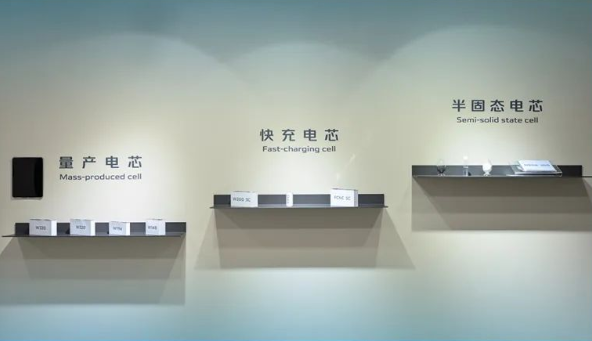

In terms of product layout, in terms of battery cells, it is planned to launch 8 self-developed battery cells including liquid, semi-solid, and solid by 2030, forming a battery production capacity of 50-80GWh.

In terms of battery pack integration, the first CTV technology will begin mass production in 2024, achieving a pack efficiency of ≥86%.

In terms of battery energy systems, through the expansion of technology, products, and business models, we will create a complete renewable energy ecosystem with "energy" as the main line, form an industrial closed loop of energy production, storage, and utilization, and realize the realization of the entire industry Maximize chain value.

In terms of system capabilities, Changan Automobile has established an Advanced Battery Research Institute with more than 1,200 battery R&D personnel, including 125 senior experts and top academic talents. In the future, another 10 billion yuan will be invested, and the battery team will reach 3,000 people by 2024.

Changan Automobile has established a mature and complete R&D management, production capacity management, supply and marketing management system, continues to tackle core technologies, and will focus on achieving new breakthroughs in material innovation, system integration innovation and other aspects.

At the Guangzhou Auto Show, Changan Automobile released its self-developed battery brand and named it Changan "Golden Bell". As the brand name implies, Changan Automobile's battery system will comprehensively solve users' concerns in terms of energy density, charge and discharge efficiency, cycle life, low-temperature performance, etc. Giving users a new experience of "long life", "true safety", "super efficient" and "fast energy replenishment".

This site previously reported that Times Changan Power Battery Co., Ltd., a battery company jointly invested and founded by Changan Automobile, Deep Blue Automobile, and CATL The company's first standard battery cell was officially rolled off the production line on November 24.

According to reports, its first standard battery uses advanced "fast ion ring graphite" and "ultra-high conductive electrolyte" material technology, with more than 6,800 quality control points embedded throughout the life cycle and more than 10,000 pieces of data. Traceable, quality reliability can reach DPPB (single defect rate of one part per billion) level, and will be integrated with 4C fast charging, which can go from 20% to 80% in just 10 minutes.

The automation rate of Times Changan factory has reached over 95%, and one battery cell can be produced in 1 second during the entire cycle from material input to finished product output. . Changan Automobile previously stated on the interactive platform that Times Changan is mainly engaged in the production and manufacturing of power cells, with an annual production capacity of 25 Gwh and can be put into production within the year.

Advertising statement: The external jump links (including but not limited to hyperlinks, QR codes, passwords, etc.) contained in the article are used to convey more information and save selection time. The results are for reference only. All articles on the site contain this statement.

The above is the detailed content of Changan Automobile: It is developing prototype cell design for new batteries, and the energy density is expected to exceed 1300-1500Wh/kg. For more information, please follow other related articles on the PHP Chinese website!