Technology peripherals

Technology peripherals

AI

AI

What are the applications of artificial intelligence in supply chain?

What are the applications of artificial intelligence in supply chain?

What are the applications of artificial intelligence in supply chain?

Using artificial intelligence (AI) is one way supply chain professionals can solve critical problems and improve global operations

AI-enhanced tools are being widely used across the supply chain chain to improve efficiency, reduce the impact of global labor shortages, and discover better, safer ways to move goods

Why should businesses use artificial intelligence?

The application of artificial intelligence can be used throughout Found in the supply chain, from the manufacturing floor to product delivery. Shipping companies are using IoT devices to collect and analyze data on transported goods and track the mechanical health and constant location of expensive vehicles and related transportation vehicles.

Customer-facing retailers are using artificial intelligence to better understand their key demographics to better predict future behavior. The list goes on and on—as long as there are goods that need to be transported from point A to point B, AI will likely be used to enhance, optimize, and analyze supply chain operations.

In the supply chain, the benefits of artificial intelligence are not as obvious as other benefits. For example, there may be benefits to using supply chain data to determine the impact of predictive analytics, but some companies report a direct link between revenue changes and the use of artificial intelligence in the supply chain. Supply Chain Tasks

AI automation of supply chain tasks can reduce the time and expense spent on traditional manual tasks. Supply chain tasks that can be automated for businesses include: Warehouse robots: Businesses can use automated systems and specialized software to move materials and perform other tasks.

Internet of Things: Automation can also provide the Internet of Things, which are physical tools with sensors, processing power, and software that connect to other devices or other communication networks and send or receive data.

- Artificial Intelligence/Machine Learning: Artificial intelligence (AI) and machine learning (ML) can help automate supply chain learning and predict user activity.

- Predictive analytics: Predictive analytics helps automate supply chains through data mining, predictive modeling and machine learning, analyzing past and current facts to predict what may happen in the future.

- Digital Process Automation (DPA): DPA automates multiple tasks for the supply chain across applications.

- Optical Character Recognition (OCR): OCR is a form of text recognition that helps supply chains.

- Data Entry Automation: Data entry can be time-consuming, but through automation, supply chain companies can get the information they need without any manual tasks.

- Automation with artificial intelligence is changing the rules of the game and has become a necessity for any supply chain industry to keep up with the rapid development

- Benefits of using artificial intelligence in the supply chain

Improved productivity: AI technologies such as automation save businesses time, allowing employees to focus on more High-level tasks, not tasks that can be accomplished through automation.

Continuous Visibility: If the business needs it, AI tools can run without any breaks or downtime.

- Used by Experts and Beginners: Artificial Intelligence can enhance the capabilities of employees who are not experts in business technology tools.

- Easier decision-making: Artificial intelligence makes the decision-making process easier, improves decision-making speed, and makes smarter decisions.

- Challenges of using artificial intelligence in supply chains

- While artificial intelligence has many benefits, no technology is perfect. Artificial intelligence is evolving and changing every day, which means the technology will become outdated or fail to meet the needs of businesses.

Difficulty scalability: AI requires large amounts of data to work effectively, so AI/machine learning: can create algorithms, Predictive models and analytical insights.

Lack of trust in artificial intelligence: With recent developments in artificial intelligence, businesses may be hesitant to incorporate it into their supply chains. Computers also don't have the same capabilities as humans, making the conversion difficult.

- Artificial Intelligence Technology Limitations: While artificial intelligence is a positive tool, it is a new tool and has not yet been fully developed. Businesses may want to automate tasks that cannot or will take more time than deducted time.

- High Cost: While AI technology can save time and money, the initial cost can be expensive for many supply chains. Integration and operational processes can also cost more than a company expects.

- Artificial intelligence machines can be complex, especially when they need to be replaced or updated. However, with the right AI solution, supply chains can benefit from AI tools.

5 examples of the application of artificial intelligence in supply chain people

(1) Demand forecasting is improving warehouse supply and demand management

Through algorithms and constraint-based modeling, machine learning is identifying supply It plays an important role in identifying patterns and influencing factors in chain data. Constraint-based modeling is a mathematical method that determines the outcome of each decision based on minimum and maximum range constraints. This data-rich modeling enables warehouse managers to make more informed decisions about inventory management

This type of big data predictive analytics is changing the way warehouse managers handle inventory by providing deep insights, This cannot be solved through human-driven processes and endless self-improving prediction cycles.

C3AI leverages artificial intelligence technology to power its inventory optimization platform, which provides warehouse managers with real-time inventory level data, including information on parts and finished goods. With the advent of the machine learning era, the platform will generate inventory recommendations based on data from production orders, purchase orders and supplier deliveries

(2) Artificial intelligence is optimizing routing efficiency and distribution logistics

In a world where almost anything can be ordered online and delivered in data, companies that don’t tightly control logistics and distribution risk falling behind. Today’s customers have higher expectations for fast, accurate shipments, and when one company fails to meet customer expectations, they are more than willing to turn to another company

McKinsey & Company reports that about 40% of first-time attempts Grocery delivery customers plan to use the services indefinitely. Customers in major markets like New York and Chicago have dozens of options for AI-driven route optimization platforms and GPS tools, such as ORION, used by logistics leader UPS. These tools are able to create the most efficient route from all possibilities, a task that traditional methods cannot accomplish because they cannot adequately analyze the countless route possibilities

(3) Machine learning Artificial intelligence is improving transportation Tool Health and Lifespan

IoT device data and other information can provide valuable insights into the health and lifespan of the expensive equipment required by vehicles in the transportation supply chain to keep goods moving. Machine learning can make maintenance recommendations and failure predictions based on past and real-time data, allowing companies to remove vehicles from the supply chain before performance issues cause a cascade of delays

Chicago-based Uptake uses artificial intelligence and machines Learn to analyze data to predict mechanical failures in a variety of vehicles and containers, including trucks, cars, rail cars, combine harvesters, and aircraft. The company uses data from IoT devices, GPS information, and data pulled directly from vehicle performance records to make predictions, which can significantly reduce downtime.

(4) Artificial intelligence insights are improving the efficiency and profitability of the loading process

Supply chain management includes a lot of detail-oriented analysis, including how goods are loaded and unloaded from containers. It's both an art and a science to determine the fastest, most efficient way to get goods onto trucks, ships and planes.

Companies like Zebra Technologies use a combination of hardware, software, and data analytics to provide real-time visibility into the loading process. These insights can be used to optimize trailer interior space and reduce the amount of "air" transported. Zebra can also help companies design faster, lower-risk, and more efficient processing protocols to manage packages.

(5) Supply chain managers are using artificial intelligence to discover ways to save costs and increase revenue

Shipping goods around the world is expensive, and it’s only getting more expensive. For example, the cost of shipping goods by sea increased by 12% in 2020, a level last seen five years ago, according to Bloomberg.

Companies like EchoGlobalLogistics use artificial intelligence to negotiate better shipping and purchasing prices, manage carrier contracts, and identify supply chain changes that lead to better profits. Users have access to a centralized database that takes into account virtually every aspect of the supply chain to provide financial decision-making recommendations.

AI innovation in supply chains is paving the way for a future where one can eventually expect to see AI-powered autonomous vehicles used throughout the supply chain. The data these platforms mine and analyze today will continue to improve costs and efficiencies in increasingly complex global supply chains.

How to implement artificial intelligence in the supply chain

In the supply chain, the application of artificial intelligence improves efficiency, visibility and optimization levels. Applying artificial intelligence technology to actual business practices can bring many benefits to enterprises. Artificial intelligence has become an important part of the development of supply chain companies and can help deal with supply chain problems

Try artificial intelligence simulation

One of the benefits of artificial intelligence is its ability to predict the results of actions. Supply chains can try this capability to improve operational efficiency through artificial intelligence simulations.

By using simulation, supply chain companies can more flexibly leverage real-life scenarios to optimize operations. AI simulation tools are effective for many aspects of the supply chain

With AI simulation, supply chain managers can make an exact digital replica of the warehouse in which they work. AI logistics can then be simulated on the digital replica to try out different optimization strategies.

Deciding what should be automated

If a supply chain is running inefficiently, it can cause serious problems throughout the supply chain. Artificial intelligence can help automate different parts of the warehouse through inventory management and, if used correctly, can save time and money.

IoT tag is a tool that can be used to track the status of different items. It communicates with an artificial intelligence center that manages updates to all inventory data. In this way, AI can alert supply chain companies of any issues

Look at the benefits of AI in cybersecurity

Cybersecurity is an essential part of handling data now Critical for any supply chain company. Cyberattacks are common, and cybercriminals use different strategies to steal data and sensitive information. Using artificial intelligence can help protect supply chain companies’ infrastructure.

Artificial intelligence is a very effective tool that can help us stay ahead of changes or risks. AI in supply chains can identify the most common patterns and predict when changes are likely to occur

Supply chain companies can leverage AI to monitor login activity, traffic, and any unusual processes on their servers. Artificial intelligence can promptly remind enterprises of these changes

(1) Artificial intelligence supply and demand analysis

Using artificial intelligence data analysis, the supply chain can understand the supply and demand situation in the next few quarters. Artificial intelligence algorithms can be used to analyze data and predict market demand and product types. Demand forecasting can reduce supply pressure in different links in the supply chain. Once supply chain companies know the quantity of products required, they can make better decisions about purchase quantities

(2) Reduce the risk of corporate errors

Due to the function of machine learning, the system can learn to allow different Processes, such as infrastructure vision, to learn how to automate based on the needs of supply chain companies.

Along with machine learning and artificial intelligence, IoT devices can collect data on how much material is used. AI data analysis algorithms can identify where materials are being used and which materials are wasted.

Summary: Artificial Intelligence in Supply Chain

Artificial intelligence in supply chain will be part of innovating better supply chain processes, thereby creating more efficient supply chains in the future. Every part of the supply chain can implement AI to automate tasks, improve operations, and enhance cybersecurity practices.

With the help of artificial intelligence tools, supply chain enterprises can grow, bring positive changes to the business, and cope with new supply chain challenges.

The above is the detailed content of What are the applications of artificial intelligence in supply chain?. For more information, please follow other related articles on the PHP Chinese website!

Hot AI Tools

Undresser.AI Undress

AI-powered app for creating realistic nude photos

AI Clothes Remover

Online AI tool for removing clothes from photos.

Undress AI Tool

Undress images for free

Clothoff.io

AI clothes remover

AI Hentai Generator

Generate AI Hentai for free.

Hot Article

Hot Tools

Notepad++7.3.1

Easy-to-use and free code editor

SublimeText3 Chinese version

Chinese version, very easy to use

Zend Studio 13.0.1

Powerful PHP integrated development environment

Dreamweaver CS6

Visual web development tools

SublimeText3 Mac version

God-level code editing software (SublimeText3)

Hot Topics

1377

1377

52

52

Bytedance Cutting launches SVIP super membership: 499 yuan for continuous annual subscription, providing a variety of AI functions

Jun 28, 2024 am 03:51 AM

Bytedance Cutting launches SVIP super membership: 499 yuan for continuous annual subscription, providing a variety of AI functions

Jun 28, 2024 am 03:51 AM

This site reported on June 27 that Jianying is a video editing software developed by FaceMeng Technology, a subsidiary of ByteDance. It relies on the Douyin platform and basically produces short video content for users of the platform. It is compatible with iOS, Android, and Windows. , MacOS and other operating systems. Jianying officially announced the upgrade of its membership system and launched a new SVIP, which includes a variety of AI black technologies, such as intelligent translation, intelligent highlighting, intelligent packaging, digital human synthesis, etc. In terms of price, the monthly fee for clipping SVIP is 79 yuan, the annual fee is 599 yuan (note on this site: equivalent to 49.9 yuan per month), the continuous monthly subscription is 59 yuan per month, and the continuous annual subscription is 499 yuan per year (equivalent to 41.6 yuan per month) . In addition, the cut official also stated that in order to improve the user experience, those who have subscribed to the original VIP

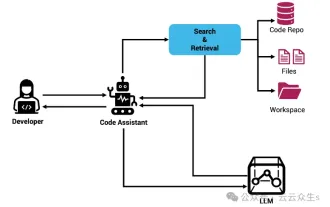

Context-augmented AI coding assistant using Rag and Sem-Rag

Jun 10, 2024 am 11:08 AM

Context-augmented AI coding assistant using Rag and Sem-Rag

Jun 10, 2024 am 11:08 AM

Improve developer productivity, efficiency, and accuracy by incorporating retrieval-enhanced generation and semantic memory into AI coding assistants. Translated from EnhancingAICodingAssistantswithContextUsingRAGandSEM-RAG, author JanakiramMSV. While basic AI programming assistants are naturally helpful, they often fail to provide the most relevant and correct code suggestions because they rely on a general understanding of the software language and the most common patterns of writing software. The code generated by these coding assistants is suitable for solving the problems they are responsible for solving, but often does not conform to the coding standards, conventions and styles of the individual teams. This often results in suggestions that need to be modified or refined in order for the code to be accepted into the application

Can fine-tuning really allow LLM to learn new things: introducing new knowledge may make the model produce more hallucinations

Jun 11, 2024 pm 03:57 PM

Can fine-tuning really allow LLM to learn new things: introducing new knowledge may make the model produce more hallucinations

Jun 11, 2024 pm 03:57 PM

Large Language Models (LLMs) are trained on huge text databases, where they acquire large amounts of real-world knowledge. This knowledge is embedded into their parameters and can then be used when needed. The knowledge of these models is "reified" at the end of training. At the end of pre-training, the model actually stops learning. Align or fine-tune the model to learn how to leverage this knowledge and respond more naturally to user questions. But sometimes model knowledge is not enough, and although the model can access external content through RAG, it is considered beneficial to adapt the model to new domains through fine-tuning. This fine-tuning is performed using input from human annotators or other LLM creations, where the model encounters additional real-world knowledge and integrates it

Seven Cool GenAI & LLM Technical Interview Questions

Jun 07, 2024 am 10:06 AM

Seven Cool GenAI & LLM Technical Interview Questions

Jun 07, 2024 am 10:06 AM

To learn more about AIGC, please visit: 51CTOAI.x Community https://www.51cto.com/aigc/Translator|Jingyan Reviewer|Chonglou is different from the traditional question bank that can be seen everywhere on the Internet. These questions It requires thinking outside the box. Large Language Models (LLMs) are increasingly important in the fields of data science, generative artificial intelligence (GenAI), and artificial intelligence. These complex algorithms enhance human skills and drive efficiency and innovation in many industries, becoming the key for companies to remain competitive. LLM has a wide range of applications. It can be used in fields such as natural language processing, text generation, speech recognition and recommendation systems. By learning from large amounts of data, LLM is able to generate text

To provide a new scientific and complex question answering benchmark and evaluation system for large models, UNSW, Argonne, University of Chicago and other institutions jointly launched the SciQAG framework

Jul 25, 2024 am 06:42 AM

To provide a new scientific and complex question answering benchmark and evaluation system for large models, UNSW, Argonne, University of Chicago and other institutions jointly launched the SciQAG framework

Jul 25, 2024 am 06:42 AM

Editor |ScienceAI Question Answering (QA) data set plays a vital role in promoting natural language processing (NLP) research. High-quality QA data sets can not only be used to fine-tune models, but also effectively evaluate the capabilities of large language models (LLM), especially the ability to understand and reason about scientific knowledge. Although there are currently many scientific QA data sets covering medicine, chemistry, biology and other fields, these data sets still have some shortcomings. First, the data form is relatively simple, most of which are multiple-choice questions. They are easy to evaluate, but limit the model's answer selection range and cannot fully test the model's ability to answer scientific questions. In contrast, open-ended Q&A

Five schools of machine learning you don't know about

Jun 05, 2024 pm 08:51 PM

Five schools of machine learning you don't know about

Jun 05, 2024 pm 08:51 PM

Machine learning is an important branch of artificial intelligence that gives computers the ability to learn from data and improve their capabilities without being explicitly programmed. Machine learning has a wide range of applications in various fields, from image recognition and natural language processing to recommendation systems and fraud detection, and it is changing the way we live. There are many different methods and theories in the field of machine learning, among which the five most influential methods are called the "Five Schools of Machine Learning". The five major schools are the symbolic school, the connectionist school, the evolutionary school, the Bayesian school and the analogy school. 1. Symbolism, also known as symbolism, emphasizes the use of symbols for logical reasoning and expression of knowledge. This school of thought believes that learning is a process of reverse deduction, through existing

SOTA performance, Xiamen multi-modal protein-ligand affinity prediction AI method, combines molecular surface information for the first time

Jul 17, 2024 pm 06:37 PM

SOTA performance, Xiamen multi-modal protein-ligand affinity prediction AI method, combines molecular surface information for the first time

Jul 17, 2024 pm 06:37 PM

Editor | KX In the field of drug research and development, accurately and effectively predicting the binding affinity of proteins and ligands is crucial for drug screening and optimization. However, current studies do not take into account the important role of molecular surface information in protein-ligand interactions. Based on this, researchers from Xiamen University proposed a novel multi-modal feature extraction (MFE) framework, which for the first time combines information on protein surface, 3D structure and sequence, and uses a cross-attention mechanism to compare different modalities. feature alignment. Experimental results demonstrate that this method achieves state-of-the-art performance in predicting protein-ligand binding affinities. Furthermore, ablation studies demonstrate the effectiveness and necessity of protein surface information and multimodal feature alignment within this framework. Related research begins with "S

Laying out markets such as AI, GlobalFoundries acquires Tagore Technology's gallium nitride technology and related teams

Jul 15, 2024 pm 12:21 PM

Laying out markets such as AI, GlobalFoundries acquires Tagore Technology's gallium nitride technology and related teams

Jul 15, 2024 pm 12:21 PM

According to news from this website on July 5, GlobalFoundries issued a press release on July 1 this year, announcing the acquisition of Tagore Technology’s power gallium nitride (GaN) technology and intellectual property portfolio, hoping to expand its market share in automobiles and the Internet of Things. and artificial intelligence data center application areas to explore higher efficiency and better performance. As technologies such as generative AI continue to develop in the digital world, gallium nitride (GaN) has become a key solution for sustainable and efficient power management, especially in data centers. This website quoted the official announcement that during this acquisition, Tagore Technology’s engineering team will join GLOBALFOUNDRIES to further develop gallium nitride technology. G