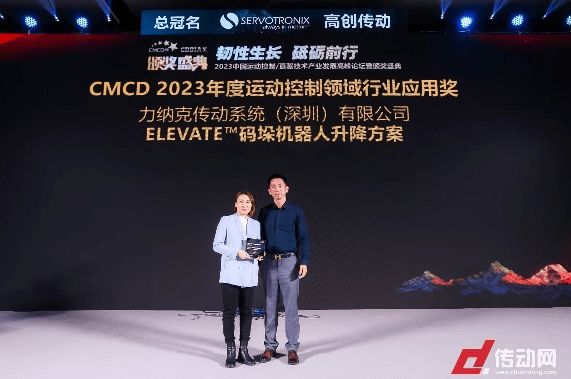

On December 22, at the "2023 CMCD Motion Control Field Annual Award" award ceremony held in Shenzhen, LINAK's innovative product "ELEVATE™ Palletizing Robot Lifting Solution" won the CMCD Industry Innovation Application Award. This is the second time LINAK has won this award and the third consecutive year it has won the CMCD Award.

As a brand with a history of more than 100 years, Danish LINAK has been committed to promoting the development of the industry with new and innovative solutions. This is due to the innovative genes and technological strength accumulated by the brand over the past century. LINAK Denmark still maintained this innovative spirit when developing the ELEVATE™ palletizing robot lifting solution.

As material handling requirements and labor costs continue to increase, the need for human-machine collaboration has become more urgent. For example, when stacking goods, relying solely on manpower is not only inefficient, but can also easily lead to additional labor costs such as work injuries. Therefore, enterprises are beginning to seek robust, intelligent, and humanized machine collaboration solutions. As an important part of modern handling, palletizing robots are used in material handling, warehousing and other operations. Through mechanization and precise control, palletizing robots free manpower from heavy and repetitive work processes. However, the range of movement of a palletizing robot is usually limited by the stroke width and height of the robotic arm.

After observing the needs of users, LINAK launched the ELEVATE™ palletizing robot lifting solution. This solution uses a lifting column with large thrust and bending moment as the base, allowing the palletizing robot to rise or fall smoothly, making full use of the longitudinal space of the warehouse space. In addition, LINAK’s ELEVATE™ lifting system can maintain higher speeds and greater flexibility while carrying a load of 100kg. Each palletization can be carried out smoothly and accurately, which means that goods can be stacked neatly, effectively saving space and reducing manual palletizing costs.

In addition, ELEVATE™ also provides a variety of interfaces and is compatible with most collaborative robots on the market. For example, users can use URCap and TMFlow to implement intelligent control and data detection of Universal Robots and OMRON TM collaborative robots. Through these interfaces, users can specify the robot's height, adjust its speed, and obtain status feedback, among other functions.

With years of experience in the field of lifting transmission and pragmatic R&D style, LINAK is committed to providing customers with simple, integrated, convenient and efficient solutions, thereby reducing learning costs and helping the industry transform palletizing operations. Take it to the next level.

The above is the detailed content of LINAK's innovative solution for lifting robots once again won the CMCD Award. For more information, please follow other related articles on the PHP Chinese website!