NVIDIA recently announced the 2023 AI and robotics innovative application scenarios, including six innovative designs including the Ella smart stroller, Soft Robotics food packaging machine and TM25S collaborative robot digital twin platform. Covering three major fields: industrial, consumer and special, three of them are robot applications. Its innovative products are Soft Robotics' mGripAI solution, Damien TM25S collaborative robot digital twin system, and Caltech wheeled deformable robot M4. Let's take a look. Get up and review it.

Soft Robotics, a company in Massachusetts, USA, recently announced that it has received US$26 million in Series C financing. After this round of financing, the company plans to use the funds to expand the commercial deployment of mGripAI. It is understood that Soft Robotics has raised a total of US$86 million in financing since its establishment.

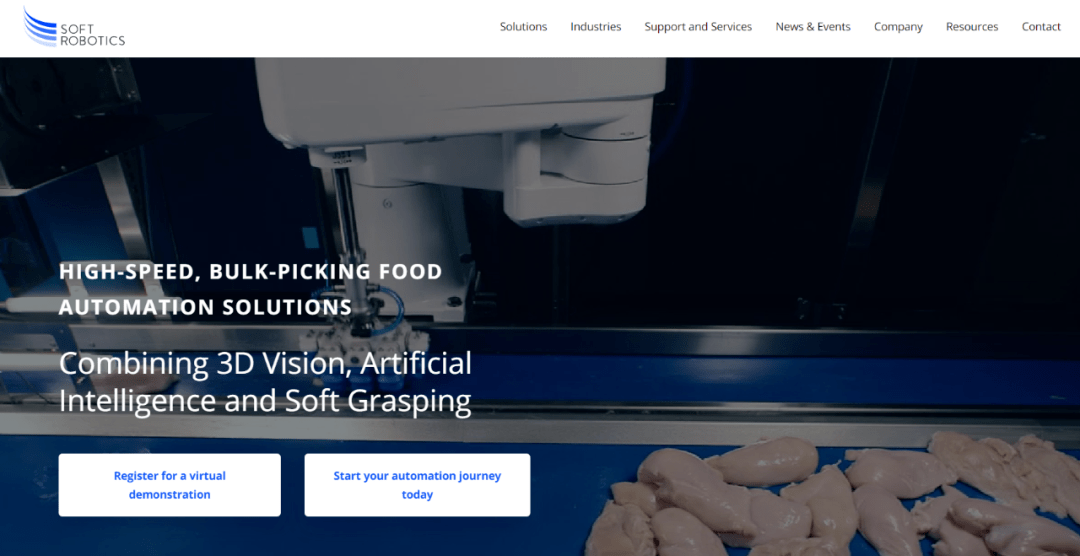

Soft Robotics is a technology company founded in 2012 by Dr. George M. Whitesides of Harvard University and is headquartered about 20 miles outside Boston. The company's mission is to provide a set of automatic picking solutions for the global food industry using unique soft robot grasping, 3D machine vision and artificial intelligence software technologies.

It is understood that mGripAI is an automation software package developed by Soft Robotics. It combines 3D vision and artificial intelligence technology to enable industrial robots to have "hand-eye" coordination capabilities. At present, mGripAI solution has been widely used in food processing

Soft Robotics used the NVIDIA Omniverse platform and the NVIDIA Isaac Sim robot simulator to create 3D renderings of chicken parts on a conveyor belt or in a box. With the ray tracing capabilities of AI and NVIDIA RTX technology, the robotic gripper can handle up to 100 grasps per minute, even in glare or changing light conditions.

In addition, mGripAI also has functions such as real-time object tracking, improved sorting accuracy, and grabbing optimization, intelligent robot motion control, and embedded object understanding.

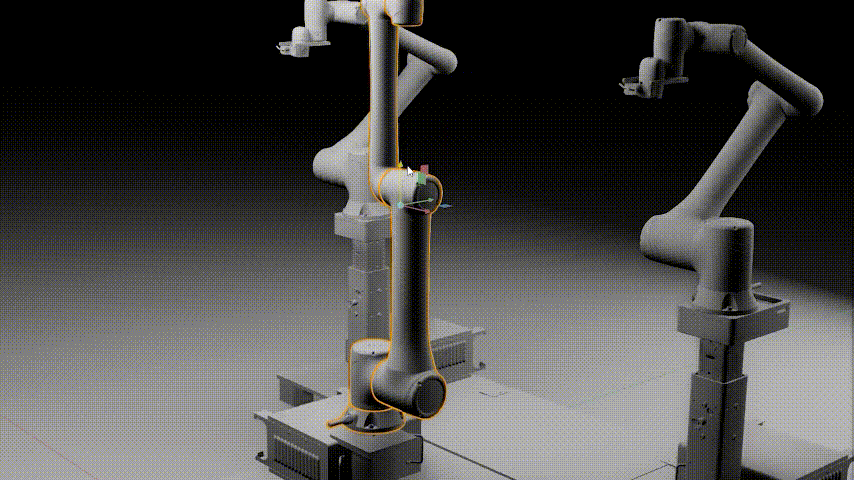

Quanta, a well-known electronics manufacturer in Taiwan, is undergoing a digital transformation of its factory. Its workshop uses the TM25S intelligent collaborative robot provided by Taiwan's Daming Company for automated inspection of product quality.

Daming Robot uses the NVIDIA Omniverse platform to build the inspection robot and the digital twin of the product to be inspected in Isaac Sim. Compared with the if...else manual programming of the real robot, using this method can reduce the operating time by more than 70%. .

Daming Robot used the optimization tools in Isaac Sim to conduct a large number of simulation program tests on NVIDIA GPUs for product quality inspection. The final results are as described in the video. This is a relatively mature solution. Through the digital twin solution, each inspection cycle is shortened by 20%.

▍Future application of Caltech’s deformable wheeled robot M4 for Mars exploration

In July this year, Caltech, the Jet Propulsion Laboratory and Northeastern University jointly developed a multi-motion mode, mobile deformable robot M4. This solution uses a wheeled robot structure design that can use high maneuverability to quickly reach and land in areas that conventional robots cannot enter. In the future, it will be widely used in scenarios such as barrier-free casualty transportation and digital agriculture. The M42 version of M4 is currently under development at NASA and is expected to become a candidate robot for Mars exploration missions.

M4 weighs about 6 kilograms, has a thrust of about 9kg, and a wheel diameter of about 30 centimeters. The fuselage is equipped with an onboard computer for underlying control and data collection, sensors (encoders, inertial measurement units, stereo cameras), and sensors for remote operation. Communication equipment, joint actuators, propulsion motors, power electronics and batteries.

The M4 transforming robot is powered by the NVIDIA Jetson platform for edge AI and robotics, a solution for building transformable drones. Through this solution, the M4 robot can achieve up to eight motion postures: including flying, rolling, crawling, squatting, balancing, rolling, reconnaissance, local operation and other actions.

Currently, the M4 can fly at a speed of 40 miles per hour and can fly for 30 minutes on a single charge. The team is working hard to design larger drones that can fly longer, carry larger payloads and fly farther.

The above is the detailed content of NVIDIA announces innovative applications for 2023. Robot innovative designs account for half of the total. For more information, please follow other related articles on the PHP Chinese website!

How oracle rounds

How oracle rounds

What does ICO mean?

What does ICO mean?

How to close port 135 445

How to close port 135 445

How to solve the problem that the msxml6.dll file is missing

How to solve the problem that the msxml6.dll file is missing

How to solve no route to host

How to solve no route to host

How to solve the problem when the computer CPU temperature is too high

How to solve the problem when the computer CPU temperature is too high

Detailed explanation of Linux fork function

Detailed explanation of Linux fork function

Commonly used database software

Commonly used database software