Introduction to common faults and maintenance methods of air compressors

Common faults and repair methods: 1. The exhaust temperature is too high, check whether the coolant is sufficient, whether the radiator is blocked, and whether the temperature control valve is working normally; 2. The compressor stops during operation, and you need to check the power supply and gas supply. bottle pressure; 3. The air compressor cannot pump out air. You need to check whether the pressure switch is damaged, whether the contacts are in good contact, whether the diaphragm is ruptured, etc.; 4. The exhaust pressure is low, check whether the air inlet valve is fully open, and whether the exhaust pipe is Check whether the air filter is blocked; 5. It is difficult to start the air compressor. Check whether the motor and power supply are normal, whether the motor is reversed, whether the motor is missing phase, etc.

Common faults and maintenance methods of air compressors are as follows:

The exhaust temperature is too high High: Check whether the coolant is sufficient, whether the radiator is blocked, whether the temperature control valve is working properly, and replace related accessories if necessary.

The compressor stops during operation: It may be a power failure or low air pressure. You need to check the power supply and cylinder pressure.

The air compressor cannot pump air: you need to check whether the pressure switch is damaged, whether the contacts are in good contact, whether the diaphragm is ruptured, etc. You need to replace related accessories.

Low exhaust pressure: Check whether the intake valve is fully open, whether the exhaust pipe is clear, whether the air filter is blocked, and replace relevant accessories if necessary.

It is difficult to start the air compressor: it is necessary to check whether the motor and power supply are normal, whether the motor is reversed, whether the motor is missing a phase, whether the motor is overloaded, and relevant accessories need to be replaced.

Air compressor oil leakage: Check whether the oil seal is damaged, whether the oil pipe joint is loose, and relevant accessories need to be replaced.

The air compressor makes abnormal noise: it is necessary to check whether the connecting rod bush and crankshaft bush are severely worn, whether the piston and piston ring are severely worn, and replace relevant accessories if necessary.

The safety valve frequently trips: it is necessary to check whether the gas contains too many impurities, whether the safety valve is loose, and relevant accessories need to be replaced.

It should be noted that when repairing the air compressor, it is necessary to follow the relevant operating specifications to avoid safety accidents. At the same time, in order to ensure the normal operation of the air compressor, regular maintenance is required.

The above is the detailed content of Introduction to common faults and maintenance methods of air compressors. For more information, please follow other related articles on the PHP Chinese website!

Hot AI Tools

Undresser.AI Undress

AI-powered app for creating realistic nude photos

AI Clothes Remover

Online AI tool for removing clothes from photos.

Undress AI Tool

Undress images for free

Clothoff.io

AI clothes remover

AI Hentai Generator

Generate AI Hentai for free.

Hot Article

Hot Tools

Notepad++7.3.1

Easy-to-use and free code editor

SublimeText3 Chinese version

Chinese version, very easy to use

Zend Studio 13.0.1

Powerful PHP integrated development environment

Dreamweaver CS6

Visual web development tools

SublimeText3 Mac version

God-level code editing software (SublimeText3)

Hot Topics

1377

1377

52

52

Fix: Microsoft Teams error code 80090016 Your computer's Trusted Platform module has failed

Apr 19, 2023 pm 09:28 PM

Fix: Microsoft Teams error code 80090016 Your computer's Trusted Platform module has failed

Apr 19, 2023 pm 09:28 PM

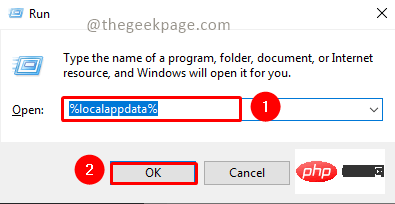

<p>MSTeams is the trusted platform to communicate, chat or call with teammates and colleagues. Error code 80090016 on MSTeams and the message <strong>Your computer's Trusted Platform Module has failed</strong> may cause difficulty logging in. The app will not allow you to log in until the error code is resolved. If you encounter such messages while opening MS Teams or any other Microsoft application, then this article can guide you to resolve the issue. </p><h2&

What does the 0x0000004e error mean?

Feb 18, 2024 pm 01:54 PM

What does the 0x0000004e error mean?

Feb 18, 2024 pm 01:54 PM

What is 0x0000004e failure? Failure is a common problem in computer systems. When a computer encounters a fault, the system usually shuts down, crashes, or displays error messages because it cannot run properly. In Windows systems, there is a specific fault code 0x0000004e, which is a blue screen error code indicating that the system has encountered a serious error. The 0x0000004e blue screen error is caused by system kernel or driver issues. This error usually causes the computer system to

What should I do if my Black Shark phone cannot be turned on? Teach you how to save yourself!

Mar 23, 2024 pm 04:06 PM

What should I do if my Black Shark phone cannot be turned on? Teach you how to save yourself!

Mar 23, 2024 pm 04:06 PM

What should I do if my Black Shark phone cannot be turned on? Teach you how to save yourself! In our daily lives, mobile phones have become an indispensable part of us. For many people, the Black Shark mobile phone is a beloved gaming phone. But it is inevitable that you will encounter various problems, one of which is that the phone cannot be turned on. When you encounter such a situation, don't panic. Here are some solutions that I hope will help you. First of all, when the Black Shark phone cannot be turned on, first check whether the phone has enough power. It may be that the phone cannot be turned on due to exhausted battery.

Honor Magic V2 RSR internal screen repair price announced: Replacing the internal screen will cost 5,279 yuan

Jan 14, 2024 am 08:48 AM

Honor Magic V2 RSR internal screen repair price announced: Replacing the internal screen will cost 5,279 yuan

Jan 14, 2024 am 08:48 AM

According to news on January 12, at 10:08 this morning, the Honor Magic V2RSR Porsche Design version was officially launched for sale. The 16GB+1TB price is 15,999 yuan, making it one of the most expensive mobile phones in Honor’s history. In addition to the high price, the price of repair and spare parts for the new machine has also been announced on the official website, which is also more expensive than the previous standard version and premium version. Overall, the internal screen and motherboard of Honor MagicV2RSR are the most expensive. An internal screen costs 5,279 yuan, and the motherboard costs 5,599 yuan. Either one is enough to buy a Huawei Mate60 mobile phone (12GB+256GB priced at 5,499 yuan). However, the screen and motherboard are also the core of a folding screen mobile phone, and they are also the difficult points to overcome with folding screens. Naturally, they are more expensive than ordinary candy bar phones.

How to Fix 0x00000001 Blue Screen Error

Feb 19, 2024 pm 11:12 PM

How to Fix 0x00000001 Blue Screen Error

Feb 19, 2024 pm 11:12 PM

What to do about 0x00000001 blue screen? The blue screen problem is a headache that many computer users often encounter. When our computer encounters a blue screen, it will suddenly stop running and display a blue screen interface with an error code. Among them, 0x00000001 is a common blue screen error code. Blue screen issues can be caused by a variety of reasons, including software errors, hardware failures, driver issues, and more. Although this problem can be frustrating, there are things we can do to resolve it. Below I will introduce some solutions to blue screen

What to do if Win10 Shared Printer 0x0000011b Fault Solution Win10 Shared Printer 0x0000011b Fault Solution

Jul 18, 2023 am 08:33 AM

What to do if Win10 Shared Printer 0x0000011b Fault Solution Win10 Shared Printer 0x0000011b Fault Solution

Jul 18, 2023 am 08:33 AM

Users who shared printers found that their win10 computers could not connect to the shared printers after upgrading the September 2021 patch. So what should they do if they encounter the win10 shared printer 0x0000011b failure? This problem is encountered by many users. , the following will give you the specific content of the win10 shared printer 0x0000011b fault solution. The method is very simple, and customers can learn it at a glance. What to do if win10 shared printer 0x0000011b fails 1. Open the control panel, enter the program and functions, and check the installed upgrade; 2. Uninstall the following patches: KB5005569/KB5005573/KB5005568/KB

Redmi Turbo 3 out-of-warranty repair price announced: motherboard price exceeds 1,500 yuan

May 02, 2024 pm 12:40 PM

Redmi Turbo 3 out-of-warranty repair price announced: motherboard price exceeds 1,500 yuan

May 02, 2024 pm 12:40 PM

According to news on May 2, Xiaomi Mall announced the out-of-warranty repair price of Redmi Turbo 3. The quotation shows that the most expensive material of Redmi Turbo 3 is the motherboard, which costs 1,530 yuan, followed by the display, which costs 390 yuan. The rear ultra-wide angle is 30 yuan, the front one is 40 yuan, the speaker is 15 yuan, the sub-panel is 45 yuan, the battery is 119 yuan, and the battery cover is 90 yuan. This is the first model of the Redmi Turbo series. The machine is equipped with Qualcomm's third-generation Snapdragon 8s processor, which is manufactured using a 4nm process. Its CPU adopts a 1+4+3 architecture, and the ultra-large core uses the third-generation Snapdragon 8s processor. The new Cortex-X4 has advanced performance and its AnTuTu score exceeded 1.75 million. In terms of screen, Redmi Turbo 3

OPPO Find X7/Ultra mobile phone repair price announced, wide-angle camera only costs 1,050 yuan!

Jan 14, 2024 pm 10:30 PM

OPPO Find X7/Ultra mobile phone repair price announced, wide-angle camera only costs 1,050 yuan!

Jan 14, 2024 pm 10:30 PM

According to news on January 12, today, OPPO officially announced the out-of-warranty repair prices for OPPO Find The specific prices are as follows: OPPO Find The battery cover assembly is 290 yuan, the front camera is 265 yuan, the rear outsole wide-angle camera (50M) is 490 yuan, and the rear ultra-wide-angle camera (50M)