Technology peripherals

Technology peripherals

It Industry

It Industry

TrendForce: Strong earthquake caused many semiconductor factories in Japan to suspend production for maintenance, but preliminary judgment is that the impact is controllable

TrendForce: Strong earthquake caused many semiconductor factories in Japan to suspend production for maintenance, but preliminary judgment is that the impact is controllable

TrendForce: Strong earthquake caused many semiconductor factories in Japan to suspend production for maintenance, but preliminary judgment is that the impact is controllable

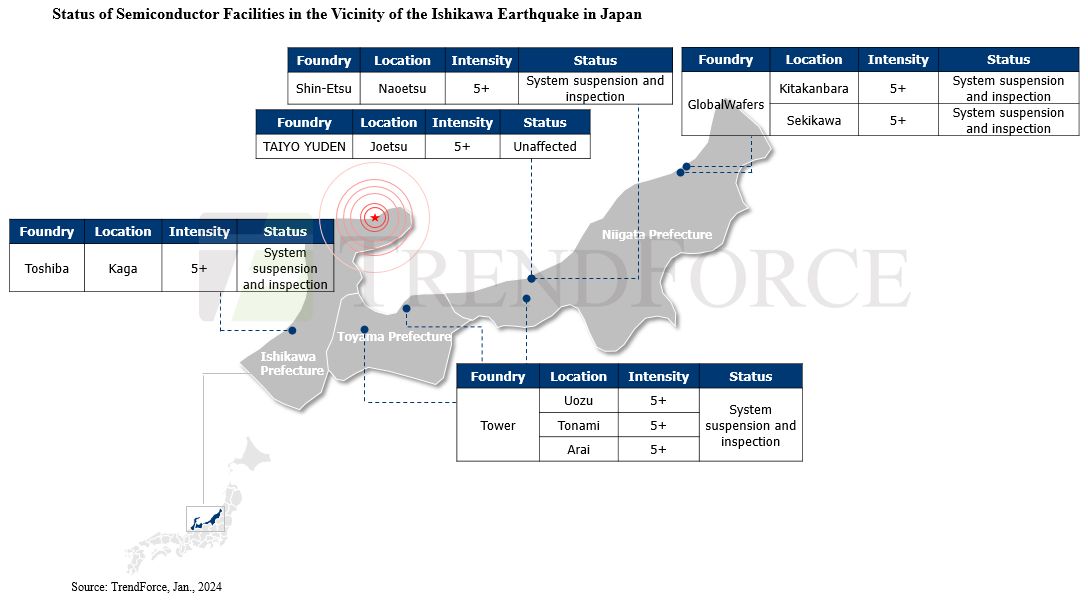

News from this site on January 3, TrendForce recently released a report stating that the strong earthquake in Japan caused the suspension of production at many local semiconductor factories. However, preliminary investigation results showed that the machines were not seriously damaged. The impact is controllable.

Regarding fabs, Shin-Etsu Chemical Industries (Shin-Etsu) and Global Wafers (GlobalWafers) in Niigata Prefecture currently A shutdown inspection is in progress.

In the silicon wafer (Raw Wafer) manufacturing process, crystal growth (Crystal Growth) is the most sensitive to earthquake shaking. However, fortunately, Shin-Etsu's crystal growth plant is mainly located in the Fukushima area, so the impact of this earthquake was relatively limited.

The Toshiba Kaga factory located in the southwest of Ishikawa Prefecture is a semiconductor factory. The factory has a six-inch plant and an eight-inch plant, and plans to build a 12-inch plant in the first half of 2024.

In addition, there are three factories of TPSCo in the three areas of Uozu, Tonami and Arai. These factories are joint ventures between Tower and Nuvoton (formerly Panasonic). Currently, these three factories are undergoing shutdown inspections and have been affected to a certain extent. The Mie Fujitsu Factory (USJC) acquired by UMC in 2019 has not been affected.

As far as MLCC is concerned, TAIYO YUDEN's Niigata factory is a brand-new factory with an earthquake resistance of level 7. Currently, the equipment has not been affected in any way.

According to reports, the MLCC (multilayer ceramic capacitor) production plants of Murata and TDK were less affected by the earthquake, with the earthquake intensity only below level 4, and no obvious damage was caused.

However, Murata has three factories in areas with earthquake intensity 5, namely Komatsu, Kanazawa and Toyama. These factories are not currently producing MLCCs and are shut down during the New Year holiday. According to current understanding, personnel have gone over to inspect the damage.

In general, since the semiconductor industry is currently in a downward cycle and market demand is relatively weak, some parts are still in stock, and most factories are within the earthquake intensity range of 4 to 5. , still within the limits of earthquake-resistant design, so the impact on semiconductor factories is limited.

The original address of the report is attached to this website. Interested users can read it in depth.

The above is the detailed content of TrendForce: Strong earthquake caused many semiconductor factories in Japan to suspend production for maintenance, but preliminary judgment is that the impact is controllable. For more information, please follow other related articles on the PHP Chinese website!

Hot AI Tools

Undresser.AI Undress

AI-powered app for creating realistic nude photos

AI Clothes Remover

Online AI tool for removing clothes from photos.

Undress AI Tool

Undress images for free

Clothoff.io

AI clothes remover

AI Hentai Generator

Generate AI Hentai for free.

Hot Article

Hot Tools

Notepad++7.3.1

Easy-to-use and free code editor

SublimeText3 Chinese version

Chinese version, very easy to use

Zend Studio 13.0.1

Powerful PHP integrated development environment

Dreamweaver CS6

Visual web development tools

SublimeText3 Mac version

God-level code editing software (SublimeText3)

Hot Topics

1386

1386

52

52

TSMC's Kumamoto plant plans to start production in April 2024, and is expected to achieve large-scale mass production in Q4, reaching a monthly production capacity of 55,000 12-inch wafers.

Dec 18, 2023 pm 09:25 PM

TSMC's Kumamoto plant plans to start production in April 2024, and is expected to achieve large-scale mass production in Q4, reaching a monthly production capacity of 55,000 12-inch wafers.

Dec 18, 2023 pm 09:25 PM

The No. 1 factory in Kumamoto Prefecture under construction by TSMC is scheduled to hold an opening ceremony in late February next year, and is scheduled to enter the final stage of production preparations in the second quarter (April to June). According to Nikkei, TSMC’s Japanese subsidiary (JASM) President Yuichi Hota said that the construction of TSMC's factory in Kumamoto is progressing smoothly and is about to be completed. They plan to start equipment import and installation in October. It is expected that TSMC’s Kumamoto factory will be put into production in April 2024 and mass production will begin in the fourth quarter. The monthly production capacity will reach 55,000 12-inch wafers. When mentioning supply chain partners, he pointed out that in addition to TSMC’s existing suppliers , and 120 Japanese companies have joined the cooperation. Currently, Japanese companies account for approximately 25% of procurement in the supply chain.

Foxconn builds AI one-stop service, and invested Sharp to enter advanced semiconductor packaging: put into production in 2026, designed to produce 20,000 wafers per month

Jul 18, 2024 pm 02:17 PM

Foxconn builds AI one-stop service, and invested Sharp to enter advanced semiconductor packaging: put into production in 2026, designed to produce 20,000 wafers per month

Jul 18, 2024 pm 02:17 PM

According to news from this site on July 11, the Economic Daily reported today (July 11) that Foxconn Group has entered the advanced packaging field, focusing on the current mainstream panel-level fan-out packaging (FOPLP) semiconductor solution. 1. Following its subsidiary Innolux, Sharp, invested by Foxconn Group, also announced its entry into Japan's panel-level fan-out packaging field and is expected to be put into production in 2026. Foxconn Group itself has sufficient influence in the AI field, and by making up for its shortcomings in advanced packaging, it can provide "one-stop" services to facilitate the acceptance of more AI product orders in the future. According to public information consulted on this site, Foxconn Group currently holds 10.5% of Sharp's shares. The group stated that it will not increase or reduce its holdings at this stage and will maintain its holdings.

It can reduce the use of expensive EUV lithography. Merck of Germany says DSA self-assembly technology will be commercially available within ten years.

Feb 05, 2024 pm 02:40 PM

It can reduce the use of expensive EUV lithography. Merck of Germany says DSA self-assembly technology will be commercially available within ten years.

Feb 05, 2024 pm 02:40 PM

According to news from this website on February 5, Anand Nambier, senior vice president of Merck of Germany, said at a press conference recently that DSA self-assembly technology will be commercialized in the next ten years, which can reduce the number of expensive EUV patterning and become an existing photolithography A great addition to the technology. Note from this site: DSA stands for Directedself-assembly, which uses the surface characteristics of block copolymers to realize the automatic construction of periodic patterns, and then induces them to eventually form the desired pattern with controllable direction. It is generally believed that DSA is not suitable for use as an independent patterning technology, but is combined with other patterning technologies (such as traditional photolithography) to produce high-precision semiconductors. ▲AnandNambier at the press conference. Picture source T

Counterpoint: In 2024Q1, the world's top five wafer equipment manufacturers' revenue from China increased by 116% year-on-year

Jun 20, 2024 pm 06:41 PM

Counterpoint: In 2024Q1, the world's top five wafer equipment manufacturers' revenue from China increased by 116% year-on-year

Jun 20, 2024 pm 06:41 PM

According to news from this website on June 20, market research agency Counterpoint Research released a blog post today stating that the revenue of the world's top five wafer equipment (WFE) manufacturers in the first quarter of 2024 fell by 9% year-on-year as customers postponed investments in cutting-edge semiconductors. . Note from this site: Among the top five, ASML’s revenue fell by 21% month-on-month and 26% year-on-year, while KLA’s revenue fell by 14% month-on-month and 5% year-on-year. Compared with 2023, Applied Materials, Lam Research and KLA reported single-digit revenue declines sequentially. Mainly due to the increase in China's DRAM shipments, the top five WFE manufacturers' revenue from China increased by 116% year-on-year in the first quarter of 2024.

Intel CEO: There are no plans to spin off the foundry business yet, and financial reports will be released independently starting in 2024Q2

Dec 16, 2023 pm 03:29 PM

Intel CEO: There are no plans to spin off the foundry business yet, and financial reports will be released independently starting in 2024Q2

Dec 16, 2023 pm 03:29 PM

According to news from this site on December 16, Intel CEO Pat Gelsinger said in a recent interview that Intel currently has no plans to spin off its foundry business. Gelsinger said Intel will not split its foundry business, but will release separate financial reports starting in the second quarter of next year. Source: Intel Our website translated Gelsinger's views, and he believed: "Under the current circumstances, the idea of internal manufacturers is the right path for us." Intel hopes to balance its chip development department and Wafer foundry business to better safeguard the assets and rights of third-party customers. Gelsinger said that most orders for the foundry business currently come from Intel itself, and it is more beneficial to keep the structure of the two areas unified.

TrendForce: Strong earthquake caused many semiconductor factories in Japan to suspend production for maintenance, but preliminary judgment is that the impact is controllable

Jan 12, 2024 pm 01:24 PM

TrendForce: Strong earthquake caused many semiconductor factories in Japan to suspend production for maintenance, but preliminary judgment is that the impact is controllable

Jan 12, 2024 pm 01:24 PM

According to this site's news on January 3, TrendForce recently released a report stating that the strong earthquake in Japan caused the suspension of production at many local semiconductor factories. However, preliminary investigation results showed that the machines were not seriously damaged and the impact was determined to be controllable. Regarding fabs, Shin-Etsu Chemical Industries (Shin-Etsu) and Global Wafers (GlobalWafers) in Niigata Prefecture are currently undergoing shutdown inspections. In the silicon wafer (RawWafer) manufacturing process, the crystal growth (CrystalGrowth) is the most sensitive to earthquake shaking. However, fortunately, Shin-Etsu's crystal growth plant is mainly located in the Fukushima area, so the impact of this earthquake was relatively limited. The Toshiba Kaga factory in southwestern Ishikawa Prefecture is a semiconductor factory. The job

2023 Q3 Wafer Foundry Industry Report: TSMC leads other companies with a 59% share, followed by Samsung with a 13% share

Dec 26, 2023 pm 02:05 PM

2023 Q3 Wafer Foundry Industry Report: TSMC leads other companies with a 59% share, followed by Samsung with a 13% share

Dec 26, 2023 pm 02:05 PM

Market research agency Counterpoint Research recently released a number of infographics summarizing the global semiconductor, foundry share and smartphone application processor (AP) share in the third quarter of 2023. Wafer foundry revenue share in the third quarter of 2023 Revenue share of foundry companies In the third quarter of 2023, the market share of the global foundry industry showed obvious levels. TSMC has taken a dominant position with an impressive 59% market share by increasing N3 production capacity and smartphone replenishment needs. Samsung OEM ranks second, occupying 13% of the market share. UMC, GlobalFoundries and SMIC have similar market shares, each accounting for about 6% of Taiwan’s market share.

Sources say Samsung has purchased a large amount of 2.5D packaging equipment to prepare for Nvidia's next-generation 'Blackwell” products

Dec 05, 2023 pm 09:34 PM

Sources say Samsung has purchased a large amount of 2.5D packaging equipment to prepare for Nvidia's next-generation 'Blackwell” products

Dec 05, 2023 pm 09:34 PM

According to TheElec, Samsung has placed an order with Japan's Shinkawa Company to purchase 16 units of 2.5D packaging bonding equipment. Sources revealed that Samsung has received 7 of the devices and may request the remaining devices if needed ▲ Source: Samsung He said that this is likely to provide HBM3 memory and 2.5 for Nvidia’s next-generation AI chips D packaging services. Samsung's HBM3, interposer and 2.5D packaging technologies may be used in Nvidia GB100 chips. However, when it comes to the GPU itself, Nvidia did not choose Samsung as a foundry partner, but chose their main partner TSMC. However, in terms of post-manufacturing processes, Nvidia chose to work with both