In the increasingly fierce competitive environment of the new energy vehicle industry, vehicle safety has become the focus of consumers' attention. As the "heart" of new energy vehicles, the safety of vehicle battery packs is even more related to the safety of the vehicle. Recently, in the China Automotive Research and Development New Energy Vehicle Battery Safety Devil Training Camp test challenge, the first model of Dongfeng Mengshi Technology, the Mengshi 917, successfully passed the test, demonstrating the hard work of "China's No. 1 luxury electric off-road vehicle" in battery safety protection. Nuclear power and ultra-tough standards. It has set a new standard for China's electric off-road battery safety protection.

The negative sill impact test simulates the most common off-road road conditions we use in outdoor off-roading. In outdoor off-roading, when the vehicle passes through ravines, there is a high probability that the vehicle chassis will Contact with hard objects may cause damage to the chassis. For new energy vehicles, the bottom of the vehicle is the crucial battery pack. If the battery pack catches fire while off-road, it will always endanger the personal safety of the driver and passengers.

In this simulation, the Warrior 917 drove down the steps at a speed of 5km/h. The gap between the bottom of the vehicle and the ground reached 250mm, allowing the bottom battery pack to directly interact with the rigidity. The obstacle collided, and we can intuitively understand from the picture that there are obvious signs of intrusion on the chassis guard of the Warrior 917.

But under such harsh conditions, the battery pack of the Warrior 917 did not leak, catch fire or explode. It can be seen that Mengshi 917 is very concerned about battery pack safety.

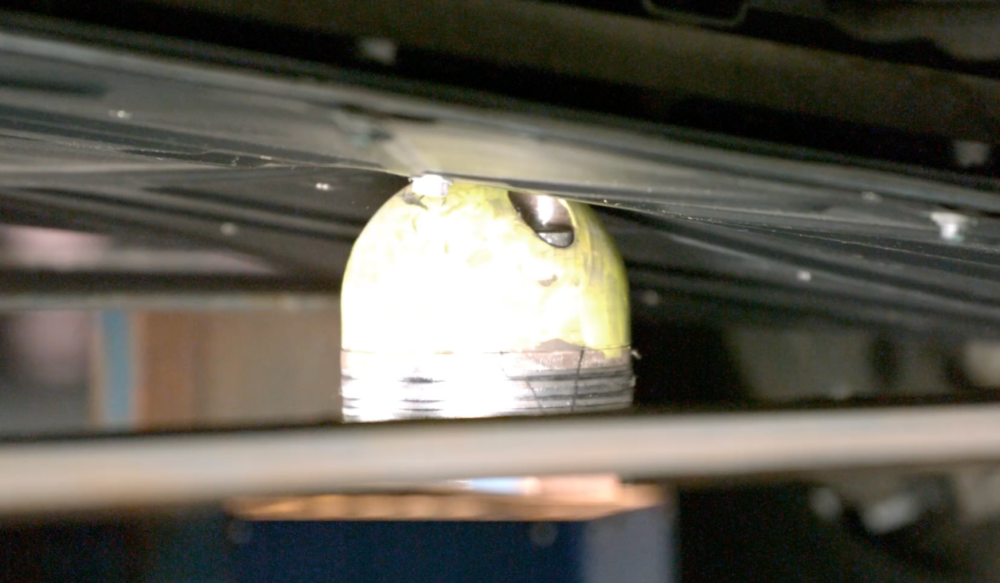

The next front and rear bottom scraping experiment made us even more worried about the Warrior 917. In the simulation test, the Warrior 917 performed bottom scraping tests at a speed of 30 km/h in the driving direction and 5 km/h in the reverse direction. The scratching obstacle is a 45# steel solid hemisphere with a height of 370mm and a diameter of 150mm. A speed of 30 km/h is not common even in outdoor off-roading.

After the Warrior 917 was scraped forward for a bottom scraping test, although debris from the vehicle’s bottom guard could be seen flying down at the scene, the battery pack could be said to be intact. No damage, it can be seen how hard the underbody guard of the Warrior 917 is!

In the subsequent bottom-scraping test at 5 km/h in the reverse direction, the Warrior 917 could even walk on flat ground and easily pass obstacles. During the test, the Mengshi 917 showed excellent sturdiness and protection performance and successfully passed this rigorous test project.

After the two tests, we thought that the Warrior 917 would be tested in some conservative projects, but who would have thought that the Warrior 917 would even play the role of the American blockbuster movie plot.

If the front and rear bottom scraping test made us worry about the Warrior 917, then in the high-speed jump test, we gained a new understanding of the overall suspension and body stability of the Warrior 917.

The flying jump test simulates the scene where the vehicle flies up and then lands on the ground on an inclined road while driving at a higher speed. It is also a scene that off-road vehicles will face at any time when rushing downhill outdoors.

Faced with a slope more than 4 meters long and 460mm high, the Warrior 917 soared into the air at a speed of 55 kilometers per hour. It was tested three times in a row. The battery pack was intact, and it even made two new slope jumps. Complete the challenge while testing.

After completing the above three tests, the Warrior 917 did not even make any preparations and directly started the wading test. Under simulation test. Warrior 917 drives in the pool at a speed of 10km/h. Due to the generation of surges, the highest water level during the test exceeded 900mm, but the Warrior 917 was still on the same level.

After the wading test, we immediately opened the door of the Warrior 917 to observe the water intrusion. It is worth mentioning that although the water level exceeded 900mm, there was no water in the Warrior 917 after the door was opened. The situation occurred, and the vehicle still maintained working status and did not send out insulation and other alarm signals.

After passing the four tests, we raised the Mengshi 917 and found that although the bottom guard of the Mengshi 917 had obvious signs of damage.

But no matter which angle you look at it, the bottom guard isolates the damage and does not intrude into the battery pack. It is enough to show how much the Warrior 917 pays attention to the protection of the battery pack. The perfect score can also double the confidence of users.

Conclusion: The success of the safety test of the Mengshi 917 battery pack fully proves Mengshi Technology’s dedication to vehicle safety and its hard power in vehicles. The four hard-core tests also allowed us to witness what is true "military quality." Through this test, Warrior 917 truly handed over its "safety business card" to everyone!

The above is the detailed content of Warrior 917 successfully completed the China Automotive Research and Development Battery Pack Safety Devil Training Camp and broke through the limits. For more information, please follow other related articles on the PHP Chinese website!

What is the difference between 5g and 4g

What is the difference between 5g and 4g

What is the difference between 4g and 5g mobile phones?

What is the difference between 4g and 5g mobile phones?

Can Douyin sparks be lit again if they have been off for more than three days?

Can Douyin sparks be lit again if they have been off for more than three days?

How to use transactionscope

How to use transactionscope

Connected but unable to access the internet

Connected but unable to access the internet

How to return to the homepage from an html subpage

How to return to the homepage from an html subpage

caj file opening method

caj file opening method

Dual graphics card notebook

Dual graphics card notebook