Industrial intelligence is important for promoting the digital transformation of the manufacturing industry, accelerating the realization of new industrialization, developing and strengthening the real economy, and promoting the deep integration of the digital economy and the real economy. significance. Recently, at the Digital Intelligence Shanghai 2023 Summit, an industrial intelligence forum called "Digital Intelligence" was held, which was a complete success. This forum gathered experts, scholars and entrepreneurs from all walks of life to discuss the latest development trends, application cases and challenges of industrial intelligence. Participants all stated that industrial intelligence is a key factor in promoting economic transformation and upgrading and improving production efficiency and quality. It is also a key factor in realizing digital transformation and the real economy. Su Aihua, Deputy Chief Engineer of Information Technology of COMAC, China Unicom Equipment Shen Zhou, senior director of the Manufacturing Corps and a leading expert on the industrial Internet of China Unicom Group, Dai Wenbo, deputy general manager of the Technology Center of CCCC Dredging Group, Qin Xiaodong, chief architect of Lenovo's intelligent manufacturing industry, and Yang Wanli, CIO of Card Saving Robot, gave keynote speeches. The roundtable session was hosted by Zheng Yu, professor and doctoral supervisor of the School of Mechanical and Power Engineering of Shanghai Jiao Tong University and deputy general manager of Shanghai Intelligent Manufacturing R&D and Transformation Functional Platform. Su Aihua, Baidu Intelligent Cloud Shanghai Regional General Manager Zhang Jiali, Yang Wanli, and Jimeng Intelligent founder and CEO Xie Mengjun exchanged views.

The guests shared observations and insights from the front lines of the industry, covering hot topics such as high-end manufacturing, 5G, industrial Internet, intelligent robots, and AI large models. At the same time, the 2023 Yangtze River Delta manufacturing digital transformation pilot demonstration list was also announced.

This time, Su Aihua, Deputy Chief Engineer of Information Technology of COMAC, shared "Exploration and Practice of Intelligent Production Control and Digital Transformation of Civil Aircraft".

"Modern civil aircraft mass production models are showing a new trend, and they are moving towards the automobile assembly line." Su Aihua said that civil aircraft products are more complex, with long and dispersed supply chains, involving hundreds of Tens of thousands of parts and components are produced in small batches per piece. Therefore, it is necessary to improve the intelligence of the production system, production process and supply chain system, and strengthen the certainty of production planning and execution to improve the ability to cope with various uncertainties and ensure Business continuity. At the same time, airworthiness is an important guarantee for the safety of civil aircraft and must run through the entire process of civil aircraft design, manufacturing, test flight, delivery and operation.

"Modern civil aircraft mass production models are showing a new trend, and they are moving towards the automobile assembly line." Su Aihua said that civil aircraft products are more complex, with long and dispersed supply chains, involving hundreds of Tens of thousands of parts and components are produced in small batches per piece. Therefore, it is necessary to improve the intelligence of the production system, production process and supply chain system, and strengthen the certainty of production planning and execution to improve the ability to cope with various uncertainties and ensure Business continuity. At the same time, airworthiness is an important guarantee for the safety of civil aircraft and must run through the entire process of civil aircraft design, manufacturing, test flight, delivery and operation.

COMAC has established an intelligent production control platform with MOM (Manufacturing Operation System) as the core. The platform is based on an open and unified digital platform for managing business and data in the aircraft manufacturing process. It has multiple capabilities such as data transmission, digital coordination tolerance, rhythmic production planning, and predictive repair processing.

In the future, civil aircraft manufacturing will present new paradigms such as forward design capabilities, collaborative research and development capabilities, human-machine integration, green and low-carbon and artificial intelligence applications. "Digital tools are blooming, and platform systems are open to all rivers." Su Aihua believes that platform systems are the foundation, supporting the flow and opening up of value and information; digital applications are tools, supporting the agility and efficiency of personalized businesses; in the future, new technologies will pass through platform systems Data integration enables large-scale applications and accelerates innovation and change in business models.

In the future, civil aircraft manufacturing will present new paradigms such as forward design capabilities, collaborative research and development capabilities, human-machine integration, green and low-carbon and artificial intelligence applications. "Digital tools are blooming, and platform systems are open to all rivers." Su Aihua believes that platform systems are the foundation, supporting the flow and opening up of value and information; digital applications are tools, supporting the agility and efficiency of personalized businesses; in the future, new technologies will pass through platform systems Data integration enables large-scale applications and accelerates innovation and change in business models.

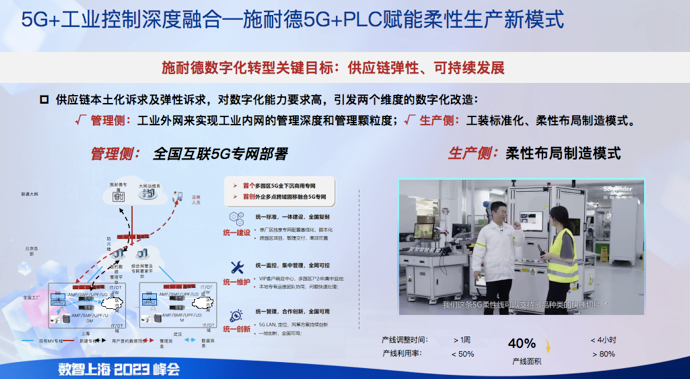

"5G Industrial Internet" is currently accelerating from the initial exploration to the stage of intensive cultivation. The application of peripheral auxiliary links in production has gradually been implemented. The core control links need to be expanded urgently. The industrial southbound control of 5G PLC Network applications have become the next step to explore new directions.

Previously, China Unicom, China Academy of Information and Communications Technology and Schneider Electric jointly released the "5G PLC Deep Integration Solution White Paper" to form a standard system for applying 5G network to the relevant experience in the field of industrial automation control to provide industrial enterprises with The flexible transformation of traditional rigid production lines provides a reference with practical value. Shen Zhou introduced that Schneider Electric’s 5G PLC enables a new model of flexible production, which can reduce the production line switching time from 7 days to 15 minutes, increase the production line utilization rate by 80%, save 50% of floor space, and increase production capacity by 12%. In the future, Shanghai Unicom will further create standard products for intelligent production lines based on this standard system to help high-quality development of the industry.

Thanks to the lush ecosystem of operating companies, solution providers, scientific research institutes, equipment manufacturers, etc., China currently leads the world in 5G applications. "In 2024, I believe that what everyone will hear most will be 5.5G (5G-A)." Shen Zhou shared the innovative breakthroughs of 5G-A in the field of industrial control and the case of China Great Wall Seiko's 5G-A flexible production line, saying that more Many new technologies will be integrated into industrial applications with the domestic pilot of 5G-A.

Dai Wenbo, deputy general manager of the Technology Center of CCCC Dredging Group, brought a report on "Digital Intelligence Innovation and Application of Dredging Offshore Equipment" and shared the intelligent frontier of the dredging industry. explore.

Dai Wenbo, deputy general manager of the Technology Center of CCCC Dredging Group, brought a report on "Digital Intelligence Innovation and Application of Dredging Offshore Equipment" and shared the intelligent frontier of the dredging industry. explore.

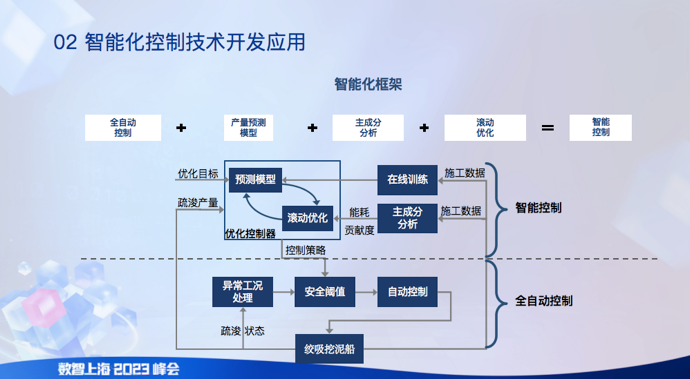

Like roads, shipping channels also need to be widened when they are not enough, relying on dredging offshore equipment such as trailing suction ships, cutter suction ships, and dredgers. The dredging mechanism is complex and involves multiple disciplines and fields such as geotechnical science, fluid mechanics, mechanical mechanics, control theory, and dredging technology, making control modeling difficult. From the perspective of the entire system, the dredging output target is related to many variables such as reamer speed, traverse speed, soil penetration depth, stepping distance, mud pump speed, environmental factors, etc. The system presents multi-parameters, nonlinearity, large time lag, and control problems. Difficult to solve.

To this end, CCCC Dredging has established a fully automatic control system to control the steps of lowering the bridge, lowering the bridge, traversing, and excavation, and set up abnormal working condition processing. As long as the parameters are set, the horizontal The movement, winch speed and mud pump speed can be fully automatically controlled. On this basis, intelligent control can be achieved through model prediction and control of excavation efficiency. It is difficult to build a model predictive control model. The cross-test modeling project in actual scenarios is huge and has a long cycle. CCCC Dredging Group collected historical data of offshore engineering equipment, trained and derived the model through the "neural network" method, solving the problem of twisting. Suction ship capacity optimization problem.

In addition, with the development of my country's shipping industry in recent years, the number of drag and suction ships has increased sharply. However, the talent echelon is broken and the dredging craftsmen are insufficient, which seriously restricts the healthy development of the industry. The rake suction simulation training system has established a navigation model, dredging model, semi-physical model, underwater terrain reconstruction, and marine environment model. It is the first three-in-one joint simulation system of dredging, navigation, and environment. "During training in the past, crew members did not dare to do many actions, fearing that mistakes would be costly and affect the subsequent construction of the ship. Now, the worst-case scenario is restarting the program and restarting the computer," said Dai Wenbo.

In addition, with the development of my country's shipping industry in recent years, the number of drag and suction ships has increased sharply. However, the talent echelon is broken and the dredging craftsmen are insufficient, which seriously restricts the healthy development of the industry. The rake suction simulation training system has established a navigation model, dredging model, semi-physical model, underwater terrain reconstruction, and marine environment model. It is the first three-in-one joint simulation system of dredging, navigation, and environment. "During training in the past, crew members did not dare to do many actions, fearing that mistakes would be costly and affect the subsequent construction of the ship. Now, the worst-case scenario is restarting the program and restarting the computer," said Dai Wenbo.

In addition, when introducing the development of core software for domestic ecological dredging construction, Dai Wenbo said, “In fact, we have also been sanctioned. We want to do this by embracing domestic CPUs, computers and operating systems. , to find a way out for our future technological development.”

In addition, when introducing the development of core software for domestic ecological dredging construction, Dai Wenbo said, “In fact, we have also been sanctioned. We want to do this by embracing domestic CPUs, computers and operating systems. , to find a way out for our future technological development.”

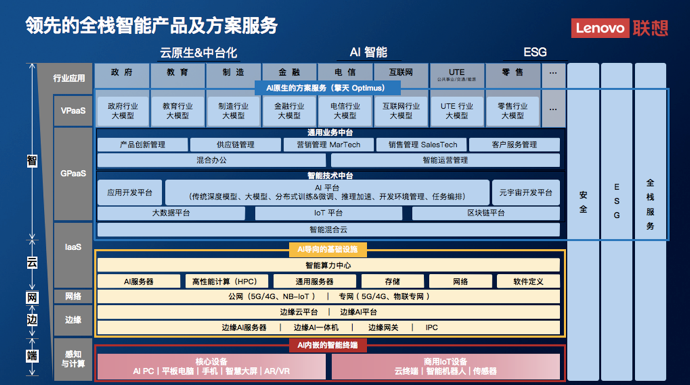

As a world-leading high-tech manufacturing company, Lenovo has extensive experience in assisting the digital and intelligent transformation of the manufacturing industry. Qin Xiaodong, chief architect of Lenovo's intelligent manufacturing industry, shared relevant experience.

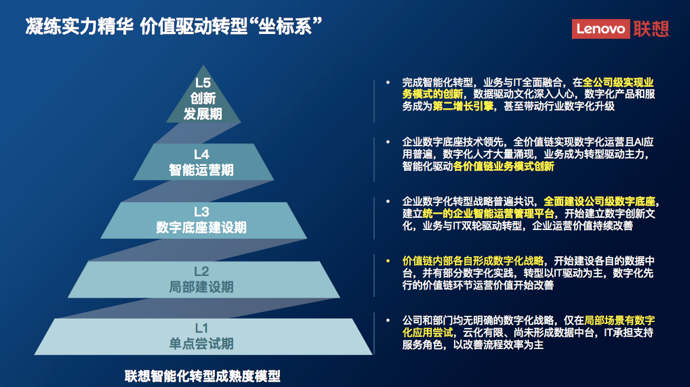

Lenovo has condensed its digital transformation methodology based on its practical experience accumulated from years of deep cultivation in the production line and its advanced exploration from automation, informatization, globalization to intelligence. and Transformation Maturity Model.

Lenovo has condensed its digital transformation methodology based on its practical experience accumulated from years of deep cultivation in the production line and its advanced exploration from automation, informatization, globalization to intelligence. and Transformation Maturity Model.

Lenovo and China Academy of Information and Communications Technology jointly created an enterprise intelligence maturity model to help enterprises accurately diagnose the maturity level of their own intelligent transformation. The model classifies the maturity level of enterprises' digital transformation as L1 Five levels to L5. Qin Xiaodong introduced that Lenovo currently has most of the L4 "intelligent operation" capabilities and a small amount of L5 "innovative development" capabilities.

L1 to L5 does not have to be a gradual path. By proactively formulating an intelligent transformation strategy and directly building a digital base based on the new IT architecture, enterprises can directly reach L3, L4 and L5, forming a leapfrog digital and intelligent transformation and development. Lenovo IT Engine "Qingtian" integrates Lenovo's new IT capabilities of "device-edge-cloud-network-intelligence" and five core capabilities of interconnection, flexible manufacturing, combination of virtual and real, closed-loop quality, and intelligent decision-making. Through "technology services" power to drive digital transformation.

L1 to L5 does not have to be a gradual path. By proactively formulating an intelligent transformation strategy and directly building a digital base based on the new IT architecture, enterprises can directly reach L3, L4 and L5, forming a leapfrog digital and intelligent transformation and development. Lenovo IT Engine "Qingtian" integrates Lenovo's new IT capabilities of "device-edge-cloud-network-intelligence" and five core capabilities of interconnection, flexible manufacturing, combination of virtual and real, closed-loop quality, and intelligent decision-making. Through "technology services" power to drive digital transformation.

Qin Xiaodong introduced that Lenovo found that "technological services" could not cover the entire industry. Lenovo Ventures invested in many companies based on "device-edge cloud network intelligence" to cultivate an innovation ecosystem and serve more new cars and new products. New manufacturing customers in energy, new materials, and new technologies, as well as traditional manufacturing customers such as steel, chemicals and energy, industrial machinery, and consumer manufacturing, achieve intelligent transformation.

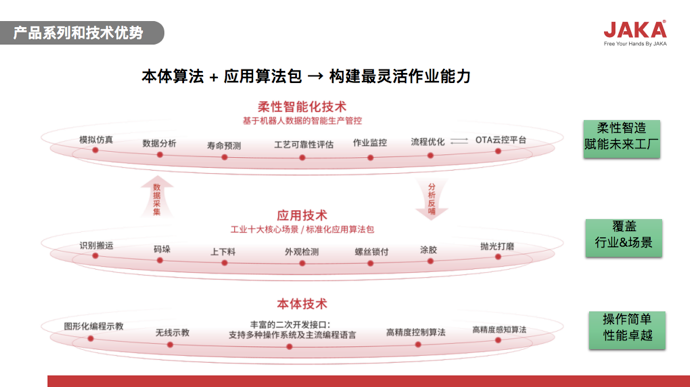

China’s Sky Eye FAST “pot cleaning” robot has sparked heated discussions. "Through this project, the Jieka robot has completed the maintenance work of the laser target on the reflective surface of the Sky Eye." Yang Wanli introduced. After nine years of accumulation, the card-saving robot has in-depth cooperation with many Fortune 500 companies such as Toyota Industrial Chain and Schneider, and has created many flexible automation benchmark cases.

In the future, Jiaka Robot will create a robot service ecosystem and build a "collaborative robot + ecosystem" through robot products, perception products, OTA smart service platforms, and digital factory construction. ”, using multi-wheel drive to empower the upgrading of the manufacturing industry and promote the ecological construction of digital factories.

COMAC attaches great importance to investment in digital platform software research and development capabilities. Su Aihua, deputy chief engineer of informatization of COMAC, said that there are many intelligent application scenarios in the long-cycle chain of aircraft manufacturing. COMAC has long been involved in artificial intelligence. In terms of applications, we will conduct tracking and research, including scenario applications in deep learning, NLP, knowledge graphs, large models, etc. In the future, we will increase work on algorithm applications and deep data mining based on early data accumulation.

For more enterprises, the first step to implement large models is to introduce large model capabilities. The Qianfan Large Model Platform launched by Baidu Intelligent Cloud is an enterprise-level large model service platform. As of December 2023, it has served more than 40,000 enterprise customers, and the cumulative number of fine-tuned models on the platform has reached 10,000. From the perspective of platform services, Zhang Jiali, general manager of Baidu Smart Cloud Shanghai, shared that both large enterprises and small and medium-sized enterprises have basically the same needs for scenario applications. However, due to security and other requirements, small and medium-sized enterprises are more likely to use public clouds, and large enterprises are more likely to use public clouds. Explore large models with private deployment. In the future, as a large amount of data is accumulated in the entire production, manufacturing, and operation process, the value of large models will become more and more obvious.

Collaborative robots are the core component of the industrial automation field and human-machine integration scenarios. Yang Wanli, CIO of Jiaka Robot, shared the difficulties and solutions to the intelligent application difficulties in the "human-machine integration" scenario, including how to carry out vision, Products such as Likong solve safety problems in industrial production as well as problems such as low product detection efficiency and misjudgment.

As a representative of local domestic digital software and industrial Internet platform companies, Xie Mengjun, founder and CEO of Jimeng Intelligence, believes that large models are a very good productivity transformation tool to achieve data-driven intelligent decision-making and release the value of data elements. The digital supply chain construction of China's large enterprises and the digital links between suppliers still need to be strengthened. At present, the basic homework of "digitalization" should be actively completed.

Zheng Yu, professor and doctoral supervisor at the School of Mechanical and Power Engineering of Shanghai Jiao Tong University and deputy general manager of Shanghai Intelligent Manufacturing R&D and Transformation Functional Platform, presided over this round table.

The above is the detailed content of Intelligent Manufacturing 2023 Summit | With the improvement of 5G and AI large model capabilities, what are the opportunities and challenges faced by the digital transformation of the manufacturing industry?. For more information, please follow other related articles on the PHP Chinese website!