How Robotics and Artificial Intelligence Can Automate Supply Chains

Automation technology is being widely used in different industries, especially in the supply chain field. Today, it has become an important part of supply chain management software. In the future, with the further development of automation technology, the entire supply chain and supply chain management software will undergo major changes. This will lead to more efficient logistics and inventory management, improve the speed and quality of production and delivery, and in turn promote the development and competitiveness of enterprises.

Forward-looking supply chain players are ready to deal with the new situation. CIOs should take the lead in ensuring the best outcomes for their organizations, and understanding the role of robotics, artificial intelligence, and automation in the supply chain is critical.

What is supply chain automation?

Supply chain automation refers to the use of technological means to reduce or eliminate human participation in supply chain activities. It covers a variety of different technologies and methods, such as machine learning, robotics, and artificial intelligence. Therefore, automation can be implemented in different ways at various points in the supply chain.

Supply chain automation has the potential to solve many current problems in the manufacturing industry, such as worker shortages, material shortages, inaccurate demand forecasts, transportation delays, etc. As supply chain automation technology matures and prices fall, it will become an integral part of the industry and not just an add-on for niche use cases.

What supply chain processes can be automated?

In theory, almost all aspects of a supply chain can be automated, but in practice, certain steps are closer to being fully automated. For example, supply chain tracking, inventory management, warehouse management, shipping, and back-office tasks are among the most common automated processes today. These automated processes increase efficiency, reduce the risk of errors, and save businesses time and money.

(1) Supply chain tracking

The supply chain involves multiple links, including raw material procurement and finished product transportation. Tracking system ensures every shipment is sent and received on time.

If a pattern emerges for a specific destination, carrier or route, the tracking system can alert relevant teams. For example, if severe weather in a particular area may affect delivery times, the customer service team can proactively notify customers of delays. Additionally, if a carrier has frequent delivery issues, business leadership teams can use the data to make informed decisions, such as whether to continue working with them. Such a tracking system can not only improve customer satisfaction, but also help companies optimize supply chain management and improve overall efficiency.

(2) Inventory Management

Proper inventory management is key to preventing overstocking and understocking, both of which can cause major problems and erosion in the supply chain Corporate profits.

Fortunately, demand planning analysis can predict whether demand for a product will change in the future. The inventory management system then generates automatic notifications when a SKU is low to prevent frustrating out-of-stock situations.

(3) Warehouse Management

Supply chain automation has changed warehouse management in many ways. For example, SCM software can automatically receive and confirm orders, while box algorithms recommend appropriately sized pallets to consolidate shipments and reduce waste.

Additionally, warehouse management tools can help eliminate or optimize repetitive tasks. For example, picking systems can help workers find products faster. Robot-guided vehicles, such as those used by Amazon warehouses to fulfill orders, can retrieve packages without human help.

(4) Transportation

Due to huge technical challenges, transportation automation still has a long way to go, but it is full of hope for the future of supply chain automation. This type of automation involves self-driving vehicles, alternative delivery equipment and route optimization technology.

Once they become feasible, self-driving trucks will solve the long-distance truck driver shortage, while the transition to delivery drones will reduce the need to use trucks and vans for last-mile deliveries. In the meantime, transportation automation would be better off focusing on optimizing delivery routes and vehicle maintenance schedules.

(5)Billing

Thanks to the power of artificial intelligence and optical character recognition (OCR), documents such as orders, receipts, and invoices can be automatically captured and processed. This reduces repetitive manual tasks, ensures greater accuracy, and makes the entire billing process more efficient.

Benefits of Supply Chain Automation

Automating all aspects of the supply chain holds great promise for businesses of all sizes.

First, automation allows human workers to spend more time and energy on value-added tasks. It also minimizes human error in tasks such as data entry, where there is a risk that information may be duplicated, incorrect or lost.

Additionally, the digital paper records created by SCM software increase visibility into all aspects of the supply chain. This enables business leaders to make more strategic decisions based on real-time data.

Supply chain automation also makes it easier to maintain organizational agility. When the unexpected happens (such as a natural disaster, widespread raw material shortages, or the COVID-19 pandemic), SCM software can help estimate the impact and develop a response plan.

These combined factors lead to faster production processes, higher profits and greater customer satisfaction.

Limitations of Supply Chain Automation

Despite the significant benefits, supply chain automation is still in its relatively early stages. As a result, there are some limitations for businesses looking to go all-in on supply chain automation.

Many technologies (especially artificial intelligence) have not yet fully matured and reached their full potential. This means that currently only the most menial, rote tasks can be automated. It takes time for the software to handle the more complex tasks currently done by humans, which is why so much SCM software currently focuses on the backend.

Cost is another significant challenge. This is especially true for robots, which are expensive to install and require ongoing maintenance to keep them running properly. As technology improves, costs will come down, but for now, it remains a significant barrier to entry for many supply chain entities.

That’s why big companies like Amazon are currently paving the way for supply chain automation, especially when it comes to robots and self-driving cars. It will be some time before small businesses with limited budgets experience the benefits of supply chain automation.

The Future of Supply Chain Automation

While supply chain automation is currently in a relatively early stage of development, it will eventually become a bargaining chip in maintaining manufacturing competitiveness, and this may happen sooner or later.

Even if their companies don’t currently have the budget to implement all types of automation, supply chain company CIOs need to understand what their competitors are doing and how automation will impact their own supply chains. To stay relevant over the years. And choosing SCM software with machine learning or artificial intelligence capabilities is a good starting point.

Hardware-intensive automation tools like warehouse robots and self-driving cars are more of an investment, but as their reliability increases and their costs fall, they will become available to smaller supply chain players. Understanding the benefits of robots in the supply chain and preparing accordingly is key.

In the near future, CIOs should focus on updating legacy systems to prepare for these coming changes. They should also hire employees with skills in key areas such as artificial intelligence, data science and robotics so that they already have the staff they need when implementing new supply chain automation initiatives.

The above is the detailed content of How Robotics and Artificial Intelligence Can Automate Supply Chains. For more information, please follow other related articles on the PHP Chinese website!

Hot AI Tools

Undresser.AI Undress

AI-powered app for creating realistic nude photos

AI Clothes Remover

Online AI tool for removing clothes from photos.

Undress AI Tool

Undress images for free

Clothoff.io

AI clothes remover

AI Hentai Generator

Generate AI Hentai for free.

Hot Article

Hot Tools

Notepad++7.3.1

Easy-to-use and free code editor

SublimeText3 Chinese version

Chinese version, very easy to use

Zend Studio 13.0.1

Powerful PHP integrated development environment

Dreamweaver CS6

Visual web development tools

SublimeText3 Mac version

God-level code editing software (SublimeText3)

Hot Topics

1377

1377

52

52

Bytedance Cutting launches SVIP super membership: 499 yuan for continuous annual subscription, providing a variety of AI functions

Jun 28, 2024 am 03:51 AM

Bytedance Cutting launches SVIP super membership: 499 yuan for continuous annual subscription, providing a variety of AI functions

Jun 28, 2024 am 03:51 AM

This site reported on June 27 that Jianying is a video editing software developed by FaceMeng Technology, a subsidiary of ByteDance. It relies on the Douyin platform and basically produces short video content for users of the platform. It is compatible with iOS, Android, and Windows. , MacOS and other operating systems. Jianying officially announced the upgrade of its membership system and launched a new SVIP, which includes a variety of AI black technologies, such as intelligent translation, intelligent highlighting, intelligent packaging, digital human synthesis, etc. In terms of price, the monthly fee for clipping SVIP is 79 yuan, the annual fee is 599 yuan (note on this site: equivalent to 49.9 yuan per month), the continuous monthly subscription is 59 yuan per month, and the continuous annual subscription is 499 yuan per year (equivalent to 41.6 yuan per month) . In addition, the cut official also stated that in order to improve the user experience, those who have subscribed to the original VIP

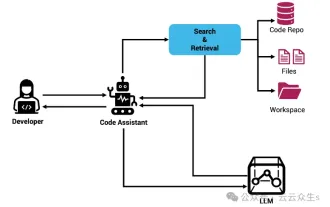

Context-augmented AI coding assistant using Rag and Sem-Rag

Jun 10, 2024 am 11:08 AM

Context-augmented AI coding assistant using Rag and Sem-Rag

Jun 10, 2024 am 11:08 AM

Improve developer productivity, efficiency, and accuracy by incorporating retrieval-enhanced generation and semantic memory into AI coding assistants. Translated from EnhancingAICodingAssistantswithContextUsingRAGandSEM-RAG, author JanakiramMSV. While basic AI programming assistants are naturally helpful, they often fail to provide the most relevant and correct code suggestions because they rely on a general understanding of the software language and the most common patterns of writing software. The code generated by these coding assistants is suitable for solving the problems they are responsible for solving, but often does not conform to the coding standards, conventions and styles of the individual teams. This often results in suggestions that need to be modified or refined in order for the code to be accepted into the application

Can fine-tuning really allow LLM to learn new things: introducing new knowledge may make the model produce more hallucinations

Jun 11, 2024 pm 03:57 PM

Can fine-tuning really allow LLM to learn new things: introducing new knowledge may make the model produce more hallucinations

Jun 11, 2024 pm 03:57 PM

Large Language Models (LLMs) are trained on huge text databases, where they acquire large amounts of real-world knowledge. This knowledge is embedded into their parameters and can then be used when needed. The knowledge of these models is "reified" at the end of training. At the end of pre-training, the model actually stops learning. Align or fine-tune the model to learn how to leverage this knowledge and respond more naturally to user questions. But sometimes model knowledge is not enough, and although the model can access external content through RAG, it is considered beneficial to adapt the model to new domains through fine-tuning. This fine-tuning is performed using input from human annotators or other LLM creations, where the model encounters additional real-world knowledge and integrates it

To provide a new scientific and complex question answering benchmark and evaluation system for large models, UNSW, Argonne, University of Chicago and other institutions jointly launched the SciQAG framework

Jul 25, 2024 am 06:42 AM

To provide a new scientific and complex question answering benchmark and evaluation system for large models, UNSW, Argonne, University of Chicago and other institutions jointly launched the SciQAG framework

Jul 25, 2024 am 06:42 AM

Editor |ScienceAI Question Answering (QA) data set plays a vital role in promoting natural language processing (NLP) research. High-quality QA data sets can not only be used to fine-tune models, but also effectively evaluate the capabilities of large language models (LLM), especially the ability to understand and reason about scientific knowledge. Although there are currently many scientific QA data sets covering medicine, chemistry, biology and other fields, these data sets still have some shortcomings. First, the data form is relatively simple, most of which are multiple-choice questions. They are easy to evaluate, but limit the model's answer selection range and cannot fully test the model's ability to answer scientific questions. In contrast, open-ended Q&A

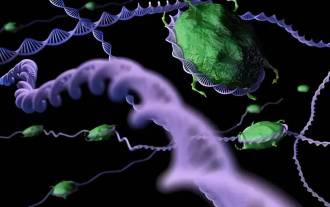

SOTA performance, Xiamen multi-modal protein-ligand affinity prediction AI method, combines molecular surface information for the first time

Jul 17, 2024 pm 06:37 PM

SOTA performance, Xiamen multi-modal protein-ligand affinity prediction AI method, combines molecular surface information for the first time

Jul 17, 2024 pm 06:37 PM

Editor | KX In the field of drug research and development, accurately and effectively predicting the binding affinity of proteins and ligands is crucial for drug screening and optimization. However, current studies do not take into account the important role of molecular surface information in protein-ligand interactions. Based on this, researchers from Xiamen University proposed a novel multi-modal feature extraction (MFE) framework, which for the first time combines information on protein surface, 3D structure and sequence, and uses a cross-attention mechanism to compare different modalities. feature alignment. Experimental results demonstrate that this method achieves state-of-the-art performance in predicting protein-ligand binding affinities. Furthermore, ablation studies demonstrate the effectiveness and necessity of protein surface information and multimodal feature alignment within this framework. Related research begins with "S

Laying out markets such as AI, GlobalFoundries acquires Tagore Technology's gallium nitride technology and related teams

Jul 15, 2024 pm 12:21 PM

Laying out markets such as AI, GlobalFoundries acquires Tagore Technology's gallium nitride technology and related teams

Jul 15, 2024 pm 12:21 PM

According to news from this website on July 5, GlobalFoundries issued a press release on July 1 this year, announcing the acquisition of Tagore Technology’s power gallium nitride (GaN) technology and intellectual property portfolio, hoping to expand its market share in automobiles and the Internet of Things. and artificial intelligence data center application areas to explore higher efficiency and better performance. As technologies such as generative AI continue to develop in the digital world, gallium nitride (GaN) has become a key solution for sustainable and efficient power management, especially in data centers. This website quoted the official announcement that during this acquisition, Tagore Technology’s engineering team will join GLOBALFOUNDRIES to further develop gallium nitride technology. G

SK Hynix will display new AI-related products on August 6: 12-layer HBM3E, 321-high NAND, etc.

Aug 01, 2024 pm 09:40 PM

SK Hynix will display new AI-related products on August 6: 12-layer HBM3E, 321-high NAND, etc.

Aug 01, 2024 pm 09:40 PM

According to news from this site on August 1, SK Hynix released a blog post today (August 1), announcing that it will attend the Global Semiconductor Memory Summit FMS2024 to be held in Santa Clara, California, USA from August 6 to 8, showcasing many new technologies. generation product. Introduction to the Future Memory and Storage Summit (FutureMemoryandStorage), formerly the Flash Memory Summit (FlashMemorySummit) mainly for NAND suppliers, in the context of increasing attention to artificial intelligence technology, this year was renamed the Future Memory and Storage Summit (FutureMemoryandStorage) to invite DRAM and storage vendors and many more players. New product SK hynix launched last year

A new era of VSCode front-end development: 12 highly recommended AI code assistants

Jun 11, 2024 pm 07:47 PM

A new era of VSCode front-end development: 12 highly recommended AI code assistants

Jun 11, 2024 pm 07:47 PM

In the world of front-end development, VSCode has become the tool of choice for countless developers with its powerful functions and rich plug-in ecosystem. In recent years, with the rapid development of artificial intelligence technology, AI code assistants on VSCode have sprung up, greatly improving developers' coding efficiency. AI code assistants on VSCode have sprung up like mushrooms after a rain, greatly improving developers' coding efficiency. It uses artificial intelligence technology to intelligently analyze code and provide precise code completion, automatic error correction, grammar checking and other functions, which greatly reduces developers' errors and tedious manual work during the coding process. Today, I will recommend 12 VSCode front-end development AI code assistants to help you in your programming journey.