Technology peripherals

Technology peripherals

AI

AI

Gigafactory: The role of artificial intelligence in shaping the future of manufacturing

Gigafactory: The role of artificial intelligence in shaping the future of manufacturing

Gigafactory: The role of artificial intelligence in shaping the future of manufacturing

The integration of manufacturing and artificial intelligence (AI) has opened a new era of modern industrial innovation. Artificial intelligence-driven supercomputing systems are at the forefront of this movement, revolutionizing traditional manufacturing processes, increasing efficiency and enabling new levels of automation and personalization. In 2022, the global artificial intelligence manufacturing market will reach US$3.8 billion, and is expected to reach approximately US$68.36 billion by 2032, with a compound annual growth rate of 33.5% from 2023 to 2032. This article will discuss how artificial intelligence is changing the face of manufacturing in unprecedented ways.

Manufacturing Transformation in the Digital Era

The importance of labor-intensive manual labor and traditional machinery in the manufacturing industry has gradually weakened. With the advent of the digital age, The integration of modern artificial intelligence algorithms and supercomputers is driving profound changes in the manufacturing industry. Smart factories have become an important pillar of today's manufacturing industry, allowing machines to communicate seamlessly and make real-time decisions, thereby increasing production efficiency and streamlining operations. The application of this advanced technology has made the manufacturing industry move towards a more intelligent and efficient direction, bringing huge development opportunities and challenges.

One of the key impacts of artificial intelligence technology in manufacturing is its ability to significantly improve the efficiency of the entire production process. Through artificial intelligence algorithms, companies can promptly discover inefficiencies and bottlenecks in the production chain, thereby optimizing processes and reducing resource waste. This data-driven approach not only reduces production costs and improves production efficiency, but also enhances the sustainability and profitability of the manufacturing industry. By detecting and analyzing large amounts of data generated by sensors, equipment and machines, artificial intelligence systems help companies achieve higher levels of production efficiency and drive the manufacturing industry towards more intelligent and sustainable development.

After understanding how the era of artificial intelligence is redefining manufacturing, let’s take a look at some practical applications of artificial intelligence in manufacturing.

Application fields of artificial intelligence super computing in manufacturing industry

Artificial intelligence super computing has profoundly changed the manufacturing industry, making the production process more efficient, flexible and intelligent. Here are some key application areas:

- Digital Twins: Leveraging artificial intelligence to create digital twins in manufacturing is an innovative approach that combines artificial intelligence with digital twin technology , which can revolutionize the way products are designed, produced and maintained. A digital twin is a virtual copy of a physical product, process, or system that can be used for a variety of purposes, including simulation, analysis, and control. When augmented by artificial intelligence, these digital twins become dynamic tools capable of learning and adapting, providing unprecedented insight and predictive capabilities.

- AI-enhanced digital twins can quickly prototype and test new designs in a virtual environment. This enables manufacturers to experiment with different materials, designs and processes without the need for physical prototypes, significantly reducing time and costs. By simulating different scenarios and conditions, AI algorithms can analyze the performance of a design and make optimization recommendations, resulting in more efficient and effective products.

- Predictive Analytics: Using artificial intelligence in manufacturing, predictive analytics represents a major leap forward for companies to predict maintenance needs, optimize production processes and improve overall efficiency. Artificial intelligence algorithms trained with the help of massive processing and computing power can analyze data from machinery sensors to detect anomalies that may indicate potential failures. By inferring these early signs, maintenance can be carried out before failure occurs, minimizing downtime.

In addition, powerful artificial intelligence models can predict the remaining service life of equipment, allowing for better planning of maintenance plans and budget allocation. This ensures that machines are only serviced when necessary, reducing unnecessary maintenance costs. Some real-life examples of predictive maintenance in manufacturing include vibration monitoring in CNC machine tools, temperature tracking in motors, oil quality in hydraulic systems, air pressure monitoring in pneumatic systems, wear analysis in conveyor belts, etc.

The application of artificial intelligence supercomputing in manufacturing is like a factory having a sixth sense that can anticipate failures before they even occur, saving millions of dollars in the process. The potential of the predictive maintenance market can be measured from the fact that the predictive maintenance market will increase from US$5.93 billion in 2023 to US$32.2 billion in 2030, with a compound annual growth rate of 27.4% from 2024 to 2030.

- Quality Control: Artificial intelligence vision systems can inspect products on the production line in real time and identify defects that may not be visible to the human eye. This ensures that only products that meet quality standards reach customers, thereby enhancing brand reputation. Machine vision is a form of industrial automation used for inspection, classification, and robot guidance. The idea is to use a combination of lighting, cameras and software to extract information from captured images.

This information can be a simple go/no-go signal, or it can be complex with the identity, direction and position of each object in the image. While machine vision itself does not involve artificial intelligence, the two technologies are becoming more closely intertwined as developers turn to neural networks to enhance machine vision algorithms and improve their accuracy. For example, Audi has begun using artificial intelligence for spot welding quality control at its Neckarsulm plant in Germany. Before machine vision was deployed, employees had to manually inspect weld quality using ultrasonics and take random samples.

- Supply chain optimization: This includes the key processes of demand forecasting and logistics optimization. Algorithms trained on artificial intelligence supercomputers can analyze market trends, historical sales data and other parameters to more accurately predict future product demand. This helps optimize inventory levels and reduces the risk of stock-outs or overstocking. Additionally, predictive analytics can improve delivery efficiency and reduce transportation costs by optimizing routes and delivery schedules based on expected orders, traffic conditions, and other variables.

Summary

The potential and benefits of using artificial intelligence in manufacturing are huge, provided there are some challenges such as infrastructure and investment, data management and skills gaps, are adequately addressed. If can solve the above challenges, in which case the technology is expected to propel manufacturing into a new era, providing solutions to long-term challenges and bringing new opportunities for innovation and efficiency. As technology continues to evolve, its impact on manufacturing is expected to grow, reshaping entire industries.

The above is the detailed content of Gigafactory: The role of artificial intelligence in shaping the future of manufacturing. For more information, please follow other related articles on the PHP Chinese website!

Hot AI Tools

Undresser.AI Undress

AI-powered app for creating realistic nude photos

AI Clothes Remover

Online AI tool for removing clothes from photos.

Undress AI Tool

Undress images for free

Clothoff.io

AI clothes remover

Video Face Swap

Swap faces in any video effortlessly with our completely free AI face swap tool!

Hot Article

Hot Tools

Notepad++7.3.1

Easy-to-use and free code editor

SublimeText3 Chinese version

Chinese version, very easy to use

Zend Studio 13.0.1

Powerful PHP integrated development environment

Dreamweaver CS6

Visual web development tools

SublimeText3 Mac version

God-level code editing software (SublimeText3)

Hot Topics

1386

1386

52

52

Bytedance Cutting launches SVIP super membership: 499 yuan for continuous annual subscription, providing a variety of AI functions

Jun 28, 2024 am 03:51 AM

Bytedance Cutting launches SVIP super membership: 499 yuan for continuous annual subscription, providing a variety of AI functions

Jun 28, 2024 am 03:51 AM

This site reported on June 27 that Jianying is a video editing software developed by FaceMeng Technology, a subsidiary of ByteDance. It relies on the Douyin platform and basically produces short video content for users of the platform. It is compatible with iOS, Android, and Windows. , MacOS and other operating systems. Jianying officially announced the upgrade of its membership system and launched a new SVIP, which includes a variety of AI black technologies, such as intelligent translation, intelligent highlighting, intelligent packaging, digital human synthesis, etc. In terms of price, the monthly fee for clipping SVIP is 79 yuan, the annual fee is 599 yuan (note on this site: equivalent to 49.9 yuan per month), the continuous monthly subscription is 59 yuan per month, and the continuous annual subscription is 499 yuan per year (equivalent to 41.6 yuan per month) . In addition, the cut official also stated that in order to improve the user experience, those who have subscribed to the original VIP

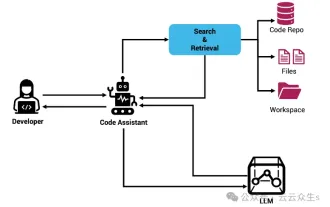

Context-augmented AI coding assistant using Rag and Sem-Rag

Jun 10, 2024 am 11:08 AM

Context-augmented AI coding assistant using Rag and Sem-Rag

Jun 10, 2024 am 11:08 AM

Improve developer productivity, efficiency, and accuracy by incorporating retrieval-enhanced generation and semantic memory into AI coding assistants. Translated from EnhancingAICodingAssistantswithContextUsingRAGandSEM-RAG, author JanakiramMSV. While basic AI programming assistants are naturally helpful, they often fail to provide the most relevant and correct code suggestions because they rely on a general understanding of the software language and the most common patterns of writing software. The code generated by these coding assistants is suitable for solving the problems they are responsible for solving, but often does not conform to the coding standards, conventions and styles of the individual teams. This often results in suggestions that need to be modified or refined in order for the code to be accepted into the application

Can fine-tuning really allow LLM to learn new things: introducing new knowledge may make the model produce more hallucinations

Jun 11, 2024 pm 03:57 PM

Can fine-tuning really allow LLM to learn new things: introducing new knowledge may make the model produce more hallucinations

Jun 11, 2024 pm 03:57 PM

Large Language Models (LLMs) are trained on huge text databases, where they acquire large amounts of real-world knowledge. This knowledge is embedded into their parameters and can then be used when needed. The knowledge of these models is "reified" at the end of training. At the end of pre-training, the model actually stops learning. Align or fine-tune the model to learn how to leverage this knowledge and respond more naturally to user questions. But sometimes model knowledge is not enough, and although the model can access external content through RAG, it is considered beneficial to adapt the model to new domains through fine-tuning. This fine-tuning is performed using input from human annotators or other LLM creations, where the model encounters additional real-world knowledge and integrates it

Seven Cool GenAI & LLM Technical Interview Questions

Jun 07, 2024 am 10:06 AM

Seven Cool GenAI & LLM Technical Interview Questions

Jun 07, 2024 am 10:06 AM

To learn more about AIGC, please visit: 51CTOAI.x Community https://www.51cto.com/aigc/Translator|Jingyan Reviewer|Chonglou is different from the traditional question bank that can be seen everywhere on the Internet. These questions It requires thinking outside the box. Large Language Models (LLMs) are increasingly important in the fields of data science, generative artificial intelligence (GenAI), and artificial intelligence. These complex algorithms enhance human skills and drive efficiency and innovation in many industries, becoming the key for companies to remain competitive. LLM has a wide range of applications. It can be used in fields such as natural language processing, text generation, speech recognition and recommendation systems. By learning from large amounts of data, LLM is able to generate text

Five schools of machine learning you don't know about

Jun 05, 2024 pm 08:51 PM

Five schools of machine learning you don't know about

Jun 05, 2024 pm 08:51 PM

Machine learning is an important branch of artificial intelligence that gives computers the ability to learn from data and improve their capabilities without being explicitly programmed. Machine learning has a wide range of applications in various fields, from image recognition and natural language processing to recommendation systems and fraud detection, and it is changing the way we live. There are many different methods and theories in the field of machine learning, among which the five most influential methods are called the "Five Schools of Machine Learning". The five major schools are the symbolic school, the connectionist school, the evolutionary school, the Bayesian school and the analogy school. 1. Symbolism, also known as symbolism, emphasizes the use of symbols for logical reasoning and expression of knowledge. This school of thought believes that learning is a process of reverse deduction, through existing

To provide a new scientific and complex question answering benchmark and evaluation system for large models, UNSW, Argonne, University of Chicago and other institutions jointly launched the SciQAG framework

Jul 25, 2024 am 06:42 AM

To provide a new scientific and complex question answering benchmark and evaluation system for large models, UNSW, Argonne, University of Chicago and other institutions jointly launched the SciQAG framework

Jul 25, 2024 am 06:42 AM

Editor |ScienceAI Question Answering (QA) data set plays a vital role in promoting natural language processing (NLP) research. High-quality QA data sets can not only be used to fine-tune models, but also effectively evaluate the capabilities of large language models (LLM), especially the ability to understand and reason about scientific knowledge. Although there are currently many scientific QA data sets covering medicine, chemistry, biology and other fields, these data sets still have some shortcomings. First, the data form is relatively simple, most of which are multiple-choice questions. They are easy to evaluate, but limit the model's answer selection range and cannot fully test the model's ability to answer scientific questions. In contrast, open-ended Q&A

SOTA performance, Xiamen multi-modal protein-ligand affinity prediction AI method, combines molecular surface information for the first time

Jul 17, 2024 pm 06:37 PM

SOTA performance, Xiamen multi-modal protein-ligand affinity prediction AI method, combines molecular surface information for the first time

Jul 17, 2024 pm 06:37 PM

Editor | KX In the field of drug research and development, accurately and effectively predicting the binding affinity of proteins and ligands is crucial for drug screening and optimization. However, current studies do not take into account the important role of molecular surface information in protein-ligand interactions. Based on this, researchers from Xiamen University proposed a novel multi-modal feature extraction (MFE) framework, which for the first time combines information on protein surface, 3D structure and sequence, and uses a cross-attention mechanism to compare different modalities. feature alignment. Experimental results demonstrate that this method achieves state-of-the-art performance in predicting protein-ligand binding affinities. Furthermore, ablation studies demonstrate the effectiveness and necessity of protein surface information and multimodal feature alignment within this framework. Related research begins with "S

SK Hynix will display new AI-related products on August 6: 12-layer HBM3E, 321-high NAND, etc.

Aug 01, 2024 pm 09:40 PM

SK Hynix will display new AI-related products on August 6: 12-layer HBM3E, 321-high NAND, etc.

Aug 01, 2024 pm 09:40 PM

According to news from this site on August 1, SK Hynix released a blog post today (August 1), announcing that it will attend the Global Semiconductor Memory Summit FMS2024 to be held in Santa Clara, California, USA from August 6 to 8, showcasing many new technologies. generation product. Introduction to the Future Memory and Storage Summit (FutureMemoryandStorage), formerly the Flash Memory Summit (FlashMemorySummit) mainly for NAND suppliers, in the context of increasing attention to artificial intelligence technology, this year was renamed the Future Memory and Storage Summit (FutureMemoryandStorage) to invite DRAM and storage vendors and many more players. New product SK hynix launched last year