Technology peripherals

Technology peripherals

It Industry

It Industry

Intel teamed up with several Japanese companies to form a back-end process automation alliance, aiming to commercialize the technology by 2028

Intel teamed up with several Japanese companies to form a back-end process automation alliance, aiming to commercialize the technology by 2028

Intel teamed up with several Japanese companies to form a back-end process automation alliance, aiming to commercialize the technology by 2028

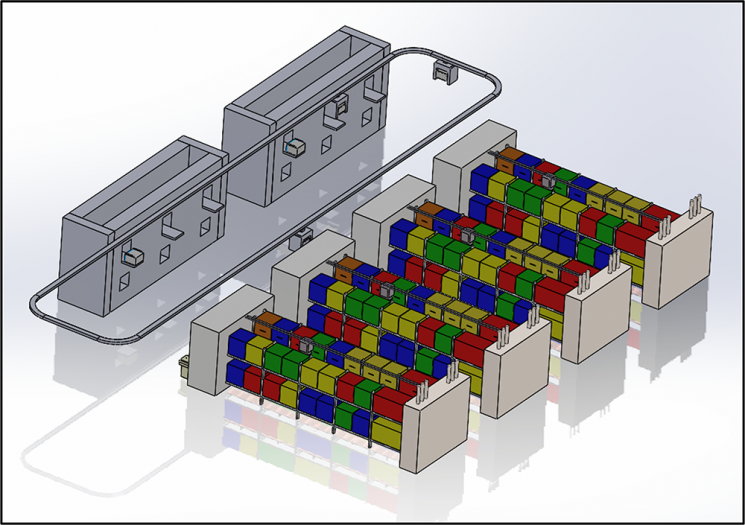

According to the official website of Mahar Engine, Intel will jointly develop semiconductor manufacturing process automation technology with 14 Japanese companies and institutions, aiming to achieve technology commercialization goals. This collaborative project aims to advance technology commercialization to at least the level of 28 years ago.

The name of the cooperative organization is "Semiconductor Back-End Process Automation and Standardization Technology Research Alliance" (note on this site: English name is Semiconductor Assembly Test Automation and Standardization Research Association, referred to as SATAS), which is owned by Intel Japan Corporation. Naga Suzuki Kunimasa serves as the representative director.

Participating Japanese companies and institutions also include Mitsubishi Research Institute, Omron, Resonac (formerly Showa Denko), Shin-Etsu Polymer, Murata Machinery, etc.

With the slowdown of Moore's Law, competition in semiconductor technology has gradually begun to shift to back-end processes. However, traditionally, back-end processes are more labor-intensive than front-end wafer production and require more Manual work.

At that time, labor costs in the United States and the United States were high, and it was difficult to compete with China and Southeast Asia in back-end processes in terms of cost. Therefore, it is necessary to realize unmanned automation of back-end production lines.

The alliance plans to establish a pilot line in Japan in the next few years, promote the standardization of back-end processes, and develop corresponding automation equipment to facilitate the unified management of multiple manufacturing, testing, and transportation equipment in the system, and ultimately achieve Completely unmanned production line.

The overall investment in the SATAS Alliance is expected to reach tens of billions of yen. The report predicts that Japan’s Ministry of Economy, Trade and Industry will also provide tens of billions of yen in funding. In the future, Intel will continue to recruit for the alliance. Japanese equipment and materials manufacturer.

The above is the detailed content of Intel teamed up with several Japanese companies to form a back-end process automation alliance, aiming to commercialize the technology by 2028. For more information, please follow other related articles on the PHP Chinese website!

Hot AI Tools

Undresser.AI Undress

AI-powered app for creating realistic nude photos

AI Clothes Remover

Online AI tool for removing clothes from photos.

Undress AI Tool

Undress images for free

Clothoff.io

AI clothes remover

AI Hentai Generator

Generate AI Hentai for free.

Hot Article

Hot Tools

Notepad++7.3.1

Easy-to-use and free code editor

SublimeText3 Chinese version

Chinese version, very easy to use

Zend Studio 13.0.1

Powerful PHP integrated development environment

Dreamweaver CS6

Visual web development tools

SublimeText3 Mac version

God-level code editing software (SublimeText3)

Hot Topics

1376

1376

52

52

Intel Core Ultra 9 285K processor exposed: CineBench R23 multi-core running score is 18% higher than i9-14900K

Jul 25, 2024 pm 12:25 PM

Intel Core Ultra 9 285K processor exposed: CineBench R23 multi-core running score is 18% higher than i9-14900K

Jul 25, 2024 pm 12:25 PM

According to news from this website on July 25, the source Jaykihn posted a tweet on the X platform yesterday (July 24), sharing the running score data of the Intel Core Ultra9285K "ArrowLake-S" desktop processor. The results show that it is better than the Core 14900K 18% faster. This site quoted the content of the tweet. The source shared the running scores of the ES2 and QS versions of the Intel Core Ultra9285K processor and compared them with the Core i9-14900K processor. According to reports, the TD of ArrowLake-SQS when running workloads such as CinebenchR23, Geekbench5, SpeedoMeter, WebXPRT4 and CrossMark

Intel N250 low-power processor exposed: 4 cores, 4 threads, 1.2 GHz frequency

Jun 03, 2024 am 10:26 AM

Intel N250 low-power processor exposed: 4 cores, 4 threads, 1.2 GHz frequency

Jun 03, 2024 am 10:26 AM

According to news from this site on May 16, the source @InstLatX64 recently tweeted that Intel is preparing to launch a new N250 "TwinLake" series of low-power processors to replace the N200 series "AlderLake-N" series. Source: videocardz The N200 series processors are popular in low-cost laptops, thin clients, embedded systems, self-service and point-of-sale terminals, NAS and consumer electronics. "TwinLake" is the code name of the new processor series, which is somewhat similar to the single-chip processor Dies using a ring bus (RingBus) layout, but with an E-core cluster to complete the computing power. The screenshots attached to this site are as follows: AlderLake-N

Intel announces Wi-Fi 7 BE201 network card, supports CNVio3 interface

Jun 07, 2024 pm 03:34 PM

Intel announces Wi-Fi 7 BE201 network card, supports CNVio3 interface

Jun 07, 2024 pm 03:34 PM

According to news from this site on June 1, Intel updated the support document on May 27 and announced the product details of the Wi-Fi7 (802.11be) BE201 network card code-named "Fillmore Peak2". Source of the above picture: benchlife website Note: Unlike the existing BE200 and BE202 which use PCIe/USB interface, BE201 supports the latest CNVio3 interface. The main specifications of the BE201 network card are similar to those of the BE200. It supports 2x2TX/RX streams, supports 2.4GHz, 5GHz and 6GHz. The maximum network speed can reach 5Gbps, which is far lower than the maximum standard rate of 40Gbit/s. BE201 also supports Bluetooth 5.4 and Bluetooth LE.

MSI launches new MS-C918 mini console with Intel Alder Lake-N N100 processor

Jul 03, 2024 am 11:33 AM

MSI launches new MS-C918 mini console with Intel Alder Lake-N N100 processor

Jul 03, 2024 am 11:33 AM

This website reported on July 3 that in order to meet the diversified needs of modern enterprises, MSIIPC, a subsidiary of MSI, has recently launched the MS-C918, an industrial mini host. No public price has been found yet. MS-C918 is positioned for enterprises that focus on cost-effectiveness, ease of use and portability. It is specially designed for non-critical environments and provides a 3-year service life guarantee. MS-C918 is a handheld industrial computer, using Intel AlderLake-NN100 processor, specially tailored for ultra-low power solutions. The main functions and features of MS-C918 attached to this site are as follows: Compact size: 80 mm x 80 mm x 36 mm, palm size, easy to operate and hidden behind the monitor. Display function: via 2 HDMI2.

ASUS releases BIOS update for Z790 motherboards to alleviate instability issues with Intel's 13th/14th generation Core processors

Aug 09, 2024 am 12:47 AM

ASUS releases BIOS update for Z790 motherboards to alleviate instability issues with Intel's 13th/14th generation Core processors

Aug 09, 2024 am 12:47 AM

According to news from this website on August 8, MSI and ASUS today launched a beta version of BIOS containing the 0x129 microcode update for some Z790 motherboards in response to the instability issues in Intel Core 13th and 14th generation desktop processors. ASUS's first batch of motherboards to provide BIOS updates include: ROGMAXIMUSZ790HEROBetaBios2503ROGMAXIMUSZ790DARKHEROBetaBios1503ROGMAXIMUSZ790HEROBTFBetaBios1503ROGMAXIMUSZ790HEROEVA-02 joint version BetaBios2503ROGMAXIMUSZ790A

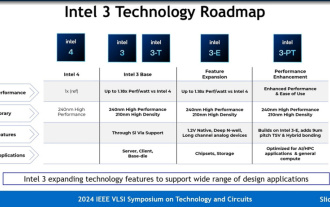

Intel explains in detail the Intel 3 process: applying more EUV lithography, increasing the frequency of the same power consumption by up to 18%

Jun 19, 2024 pm 10:53 PM

Intel explains in detail the Intel 3 process: applying more EUV lithography, increasing the frequency of the same power consumption by up to 18%

Jun 19, 2024 pm 10:53 PM

According to news from this site on June 19, as part of the 2024 IEEEVLSI seminar activities, Intel recently introduced the technical details of the Intel3 process node on its official website. Intel's latest generation of FinFET transistor technology is Intel's latest generation of FinFET transistor technology. Compared with Intel4, it has added steps to use EUV. It will also be a node family that provides foundry services for a long time, including basic Intel3 and three variant nodes. Among them, Intel3-E natively supports 1.2V high voltage, which is suitable for the manufacturing of analog modules; while the future Intel3-PT will further improve the overall performance and support finer 9μm pitch TSV and hybrid bonding. Intel claims that as its

Intel Panther Lake mobile processor specifications exposed: up to '4+8+4' 16-core CPU, 12 Xe3 core display

Jul 18, 2024 pm 04:43 PM

Intel Panther Lake mobile processor specifications exposed: up to '4+8+4' 16-core CPU, 12 Xe3 core display

Jul 18, 2024 pm 04:43 PM

According to news from this site on July 16, following the revelation of the specifications of the ArrowLake desktop processor and the BartlettLake desktop processor, blogger @jaykihn0 released the specifications of the mobile U and H versions of the Intel PantherLake processor in the early morning. The Panther Lake mobile processor is expected to be named the Core Ultra300 series and will be available in the following versions: PTL-U: 4P+0E+4LPE+4Xe, 15WPL1PTL-H: 4P+8E+4LPE+12Xe, 25WPL1PTL-H: 4P+8E+4LPE+ 4Xe, 25WPL1. The blogger also released the 12Xe nuclear display version of the PantherLake processor.

Innolux plans to mass-produce fan-out panel-level semiconductor packaging technology by the end of the year

Aug 07, 2024 pm 06:18 PM

Innolux plans to mass-produce fan-out panel-level semiconductor packaging technology by the end of the year

Aug 07, 2024 pm 06:18 PM

According to news from this site on August 6, Yang Zhuxiang, general manager of Innolux Corporation, said yesterday (August 5) that the company is actively deploying and promoting semiconductor fan-out panel-level packaging (FOPLP) and is expected to mass-produce ChipFirst before the end of this year. The contribution of process technology to revenue will be apparent in the first quarter of next year. Fenye Innolux stated that it is expected to mass-produce the redistribution layer (RDLFirst) process technology for mid-to-high-end products in the next 1-2 years, and will work with partners to develop the most technically difficult glass drilling (TGV) process, which will take another 2-3 years. It can be put into mass production within a year. Yang Zhuxiang said that Innolux’s FOPLP technology is “ready for mass production” and will enter the market with low-end and mid-range products.